Tailored Overhead Cranes for Aerospace: High Precision, Efficience, Safety and Reliability

Tailored Overhead Cranes for Aerospace meet the industry’s unique demands, characterized by specialized plant structures, high-value products, complex assembly processes, stringent precision requirements, and large component dimensions. These factors place extremely high demands on the supporting crane equipment. The use of specialized multi-point and multi-layer framework structures significantly increases the complexity of crane design, manufacturing, and installation, requiring enhanced quality management and additional safety features to ensure crane safety and reliability.

Henan Kuangshan Crane’s products have been utilized by numerous companies domestically and internationally within the aviation and space industry, receiving high praise for their advanced technology, superior performance, and reliable quality. Overhead cranes for the aerospace sector include cleanroom cranes, multipoint hanging cranes, interlock transfer cranes, explosion proof overhead cranes, and overhead cranes with lower rotating beam.

Cleanroom cranes

Multipoint hanging cranes

Interlock transfer cranes

Explosion proof overhead cranes

Overhead cranes with lower rotating beam

Cleanroom Cranes

In the aircraft manufacturing process, cleanroom cranes (dust-free cranes) are widely used. Aerospace materials, such as polyimide, are extensively applied in various areas, including aerospace engine components, aircraft fuselage structural materials, and aviation electrical components.

However, the manufacturing process of polyimide materials imposes extremely high requirements on the environment and equipment. First, contamination from impurities and dust must be avoided during production to ensure material purity and performance. Additionally, parameters such as temperature and pressure need to be precisely controlled throughout the manufacturing process to maintain the stability of the material’s structure and performance. These requirements make clean room cranes indispensable in polyimide aerospace material workshops.

In polyimide aerospace material workshops, cleanroom overhead cranes are commonly used in several areas: raw material handling, production line material handling, and equipment maintenance and replacement.

Multipoint Hanging Cranes

Aviation multipoint hanging cranes are specialized lifting products designed for the aerospace industry, catering to the requirements of grid-structure facilities and suited for precise assembly, efficient cross-aisle material handling, and lifting of irregular workpieces. This type of hangar crane minimizes the impact of crane weight on the roof structure of such facilities and helps reduce building height, saving significantly on facility construction costs.

Applications include aircraft manufacturing plants, maintenance hangars, painting hangars, and dismantling hangars, accommodating a full range of aircraft such as the A380, A330, B747, B787, C919, C929, and Y20. With a maximum span of 90 meters and up to 7 suspension points, these aircraft hangar cranes offer the following advantages:

- Lightweight design, low wheel pressure, compact height, high efficiency, and eco-friendliness

- Flexible main beam and adaptive suspension points, eliminating track wear issues, ensuring smooth, safe, and reliable operation

- Polyurethane-coated wheels for quiet, clean movement

- Automatic adjustment capability

- Maintenance-free

Interlock Transfer Cranes

The interlock crane is a versatile crane used for various transport operations in aircraft maintenance centers. Interlocking bridge cranes enable cross-aisle transfer between adjacent crane bridges, allowing remote-controlled platforms or lift vehicles to move seamlessly throughout the entire hangar.

Explosion Proof Overhead Cranes

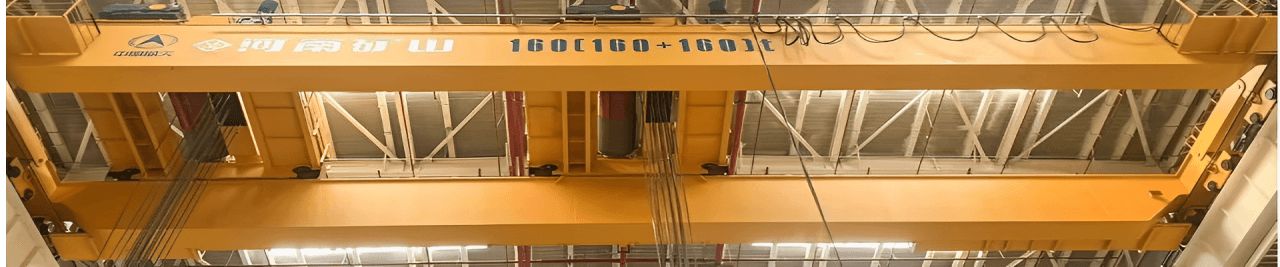

The overhead crane with lower rotating beam, manufactured by Henan Kuangshan Crane for the Xi’an Aerospace Composite Materials Research Institute, represents another innovative product following the 160t+160t explosion proof crane. This crane fills a gap in the application of overhead cranes with lower rotating beam in the aerospace sector. The project’s crane incorporates modular design, finite element structural analysis improvements, high information integration, and a unique dual lifting hook design with control precision under 1mm. These features enhance production efficiency and operational safety for the customer.

The Xi’an Aerospace Composite Materials Research Institute is a leading manufacturer of composite material casings, nozzles, and large composite launch tubes for solid rocket engines in China. Henan Kuangshan Crane has established a long-term strategic partnership with the institute.

As a key crane equipment supplier for China’s aerospace projects, Henan Kuangshan Crane provides essential support through research and development, technological innovation, service optimization, and quality enhancement. The company’s contributions have been highly recognized by its clients. In 2024, China’s aerospace sector anticipates approximately 100 launch missions. Henan Kuangshan Crane will support launches, including the Shenzhou 18 manned spacecraft, Tianzhou 8 cargo spacecraft, Shenzhou 20 manned spacecraft, and Long March 2F rocket, further contributing to China’s aerospace advancement.

お問い合わせ

- 製品の無料で迅速な見積もり。

- 製品カタログを提供します。

- 私達の会社からのあなたのローカル クレーン プロジェクト。

- 私たちのエージェントになって手数料を稼ぎましょう。

- ご不明な点がございましたら、お問い合わせください。