- EQUIPMENT

- special cranes

-

Industry Crane

-

Industry Crane

-

Tundish Cranes

-

Slab Cranes

-

Scrap Cranes

-

Billet Cranes

-

Coil,Bar and Plate Handling Cranes

-

Cement And Precast Crane

-

Power Station Crane

-

Ladle Cranes

-

Paper Industry Cranes

-

Waste to Energy Cranes and Biomass Cranes

-

Tailored Overhead Cranes for Aerospace: High Precision, Efficience, Safety and Reliability

-

-

Hoist & Winch Trolley

-

Casting Electric Wire Rope Hoist

-

European Model Electric Hoist

-

Explosion-proof Electric Hoist

-

Low-headroom Electric Hoist

-

Electric Chain Hoist

-

2 Types Explosion-Proof Electric Chain Hoists for Hazardous Zones: Gas & Dust Protection

-

2 Types Explosion-Proof Electric Wire Rope Hoists for Industrial Safety: Reliable Gas & Dust-Proof Solutions

-

Manual Hoists for Precision Lifting: Explore 3 Proven Types for Power-Free Operation

-

-

CRANE Spreader

-

Crane Electromagnetic Lifting Magnets

-

Lifting Electromagnet for Turning and Side Hung

-

Lifting Electromagnet for Thick Plate

-

Specialized Electromagnet for Lifting Steel Plates

-

Lifting Electromagnets for Lifting Steel Plates

-

Lifting Electromagnet for Heavy Rail and Profiled Steel

-

Lifting Electromagnet for High Speed Wier(Coiled Bar)

-

Lifting Electromagnet for Rebar and Steel Pipe

-

Lifting Electromagnet for Bundled Rebar and Profiled Steel

-

Lifting Electromagnet for Billet, Girder Billet and Slab

-

Lifting Electromagnet for Steel Scraps

-

- Crane Spreader

- Crane Lifting Tongs and Clamps

-

Crane Electromagnetic Lifting Magnets

- CRANE PARTS

- Transfer Cart

Environmental Protection And Embark The Green Development.

19 Sep, 2018

Spacious and bright workshop, Blue ventilation ducts throughout the workshop,

Become a beautiful landscape in Henan mining workshop

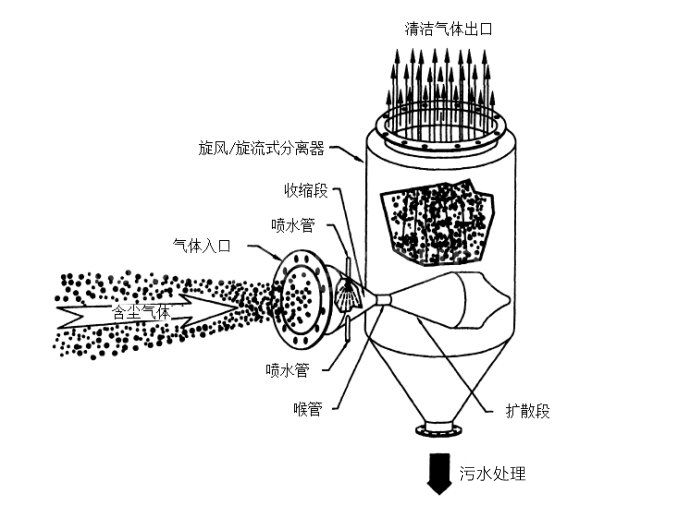

This is a wet dust removal and environmental protection equipment developed by Henan Mine based on the characteristics of the crane manufacturing workshop. It is commonly known as “water dust removal equipment”. It is a close contact between dusty gas and liquid (usually water), using inertial collision of water droplets and particles. And use the sufficient mixing of water and dust to capture soot particles.

The wet dust removal device can remove water vapor and some toxic and harmful gas pollutants in the gas while removing dust particles of dusty gas. Therefore, the wet dust remover can remove dust and treat the gas as exhaust gas. The utility model has the advantages of simple structure, small occupied area, convenient operation and maintenance and high purification efficiency, and has high exhaust gas treatment efficiency for purifying high specific resistance, high humidity, high temperature, flammable and explosive dust-containing gas. Minimize the possibility of fire and explosion. The air quality in the workshop has been significantly improved.

As a responsible crane manufacturer, Henan Mine insists on taking environmental protection work as the top political task of the company in the current and future period. It is willing to invest heavily, according to system planning, regardless of cost, no return, and construction period. Although the company has increased the cost of purchasing and renovating environmental protection facilities, we believe it is necessary and worthwhile.

In recent years, the company has increased investment in new technologies, new equipment, new product research and development, etc., vigorously develop green manufacturing, and seek transformation in green development.

- First, process innovation, reduce energy consumption

Together with Siemens, we have implemented the intelligent production line transformation of European cranes, and the digital improvement of the crane manufacturing process will create a world-class crane digital factory; intelligent, energy-saving, lightweight, improved, popularized and popularized crane products, Promote Henan mining crane products to reach world-class level.

- Second, machine substitution, energy saving

Dismantle the boiler with high consumption and polution

- Third, new products, lightweight environmental protection

Do you like what we do?Share it