- EQUIPMENT

-

special cranes

-

Garbage Grab Crane

-

Foundry Overhead Crane

-

Explosion-proof Overhead Crane

-

Tongs Overhead Crane

-

Overhead Crane with Carrier-beam

-

Electromagnetic Overhead Cranes

-

Diesel Hydraulic Straddle Carrier: Flexible Operation and Affordable Solution for Container Handling

-

Upper Spillway Gate Gantry Crane: Reliable Solution for Dam Gate Hoisting and Hydropower Station Operations

-

Harbour Portal Crane: Powerful and Intelligent Solutions for Efficient Port Handling

-

Coke Pot Crane for CDQ: Exceptional Heavy-Duty Red-Hot Coke Handling

-

Emergency Rescue Specialized Crane for Water-Rescue Simulation: Engineered for Lifesaving Training

-

Intelligent Grab Bucket Overhead Crane: Powerful, Precise and Unmanned Bulk Material Handling Solution

-

Custom Multi-Point Suspension Overhead Crane for Large-Span and Load-Sensitive Industrial Buildings

-

Electrolytic Copper Cranes: Specialized in Efficient Cathode Plate Tank Loading and Transfer

-

Nuclear Polar Cranes: Multi-Function Lifting Machinery For Nuclear Power Plants

-

-

Industry Crane

-

Industry Crane

-

Tundish Cranes

-

Slab Cranes

-

Scrap Cranes

-

Billet Cranes

-

Coil,Bar and Plate Handling Cranes

-

Cement And Precast Crane

-

Power Station Crane

-

Ladle Cranes

-

Paper Industry Cranes

-

Waste to Energy Cranes and Biomass Cranes

-

Tailored Overhead Cranes for Aerospace: High Precision, Efficience, Safety and Reliability

-

Anode Baking Multifunctional Cranes: Versatile, High-Temp Resistant & Smart-Controlled Must-Have for Electrolytic Aluminum Industry

-

Multifunctional Crane For Electrolytic Aluminum: Fulfills All Aluminum Electrolysis Processes, Boosts Plant Efficiency

-

Warehouse Stacker Crane for AS/RS: High-Efficiency, Reliable, Fully Automated Storage

-

Slab Handling Overhead Crane: Metallurgical-Grade Crane for Continuous Casting and Slab Yards

-

Anode Carbon Block Stacking Cranes: 6-Layer Stacking, A Lifting Solution for Carbon Plants’ Efficient Transfer

-

Quenching Crane for Heat Treatment: Process-Oriented Overhead Crane Solution

-

Safe & Stable Scrap Charging Overhead Crane for Metallurgical Feeding Operations

-

Forging Overhead Crane: Reliable Lifting Equipment for Heavy-Duty Forging Workshops

-

Mold Handling Crane for AAC Production Line: Reliable Engineered Fixed-Position Lifting Solution

-

Pickling Overhead Cranes: For Acid Mist Environments in Non-ferrous Metal Smelting

-

-

Hoist & Winch Trolley

-

Casting Electric Wire Rope Hoist

-

European Model Electric Hoist

-

Explosion-proof Electric Hoist

-

Low-headroom Electric Hoist

-

Electric Chain Hoist

-

2 Types Explosion-Proof Electric Chain Hoists for Hazardous Zones: Gas & Dust Protection

-

2 Types Explosion-Proof Electric Wire Rope Hoists for Industrial Safety: Reliable Gas & Dust-Proof Solutions

-

Manual Hoists for Precision Lifting: Explore 3 Proven Types for Power-Free Operation

-

Air Pneumatic Hoists: 4 Specialized Designs for Precision, Safety, and Harsh Environments

-

HC Type Electric Hoist: Heavy-duty Wire Rope Hoist for Factory Heavy Lifting

-

-

CRANE Spreader

-

Crane Electromagnetic Lifting Magnets

-

Lifting Electromagnet for Turning and Side Hung

-

Lifting Electromagnet for Thick Plate

-

Specialized Electromagnet for Lifting Steel Plates

-

Lifting Electromagnets for Lifting Steel Plates

-

Lifting Electromagnet for Heavy Rail and Profiled Steel

-

Lifting Electromagnet for High Speed Wier(Coiled Bar)

-

Lifting Electromagnet for Rebar and Steel Pipe

-

Lifting Electromagnet for Bundled Rebar and Profiled Steel

-

Lifting Electromagnet for Billet, Girder Billet and Slab

-

Lifting Electromagnet for Steel Scraps

-

- Crane Spreader

- Crane Hook

- Crane Lifting Tongs and Clamps

-

Crane Electromagnetic Lifting Magnets

- CRANE PARTS

- Transfer Cart

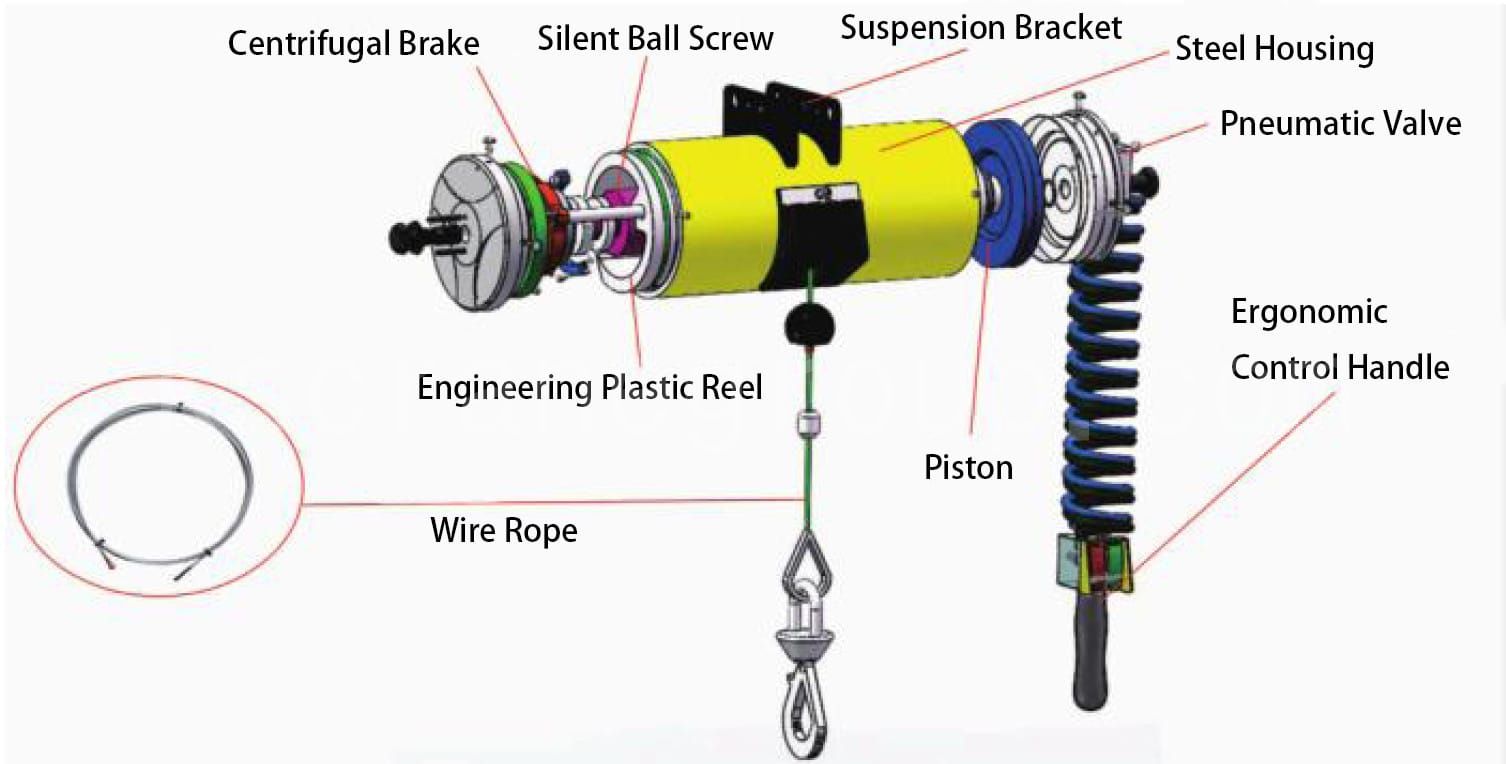

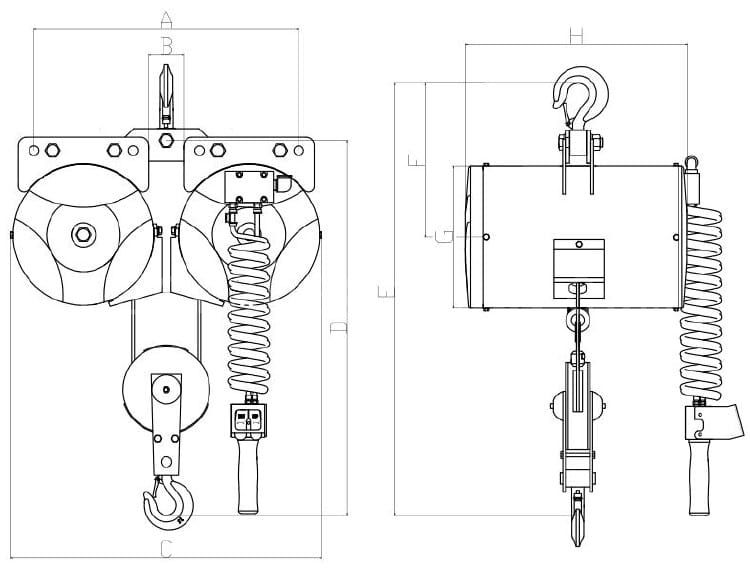

Air Pneumatic Hoists: 4 Specialized Designs for Precision, Safety, and Harsh Environments

Air pneumatic hoist is also known as an air hoist. Pneumatic hoist is a kind of pneumatic power handling equipment, which uses compressed air as the power source, through the transmission mechanism, the balance of the object’s own gravity and the pressure in the cylinder to achieve the lifting and lowering movement of heavy objects.

Air Operated Hoist Performance Advantages

Safety:

- Powered by compressed air, non-sparking operation.

- With air break protection function, even if the air source is suddenly cut off, the heavy weight will not fall.

- With overload protection function, it is impossible to lift the weight that exceeds the rated load.

- Built-in centrifugal brake function prevents sudden and rapid lifting caused by misuse.

High efficiency:

- Fast rising and falling speed, the fastest can be up to 1m/s.

- Infinitely variable speed function, the rising speed can be freely controlled according to the lifting weight.

Precision:

- With self-adaptive ‘floating' function, when the parts are lifted in a ‘gravity-free' state, it is easy to achieve precise positioning and assisted assembly.

Energy saving:

- Extremely low air consumption, the average air consumption per working cycle is about 0.21m>/h, which is 1/50th of the air consumption of pneumatic hoists.

- Clean and oil-free operation, can be used for a long time by pre-filling lubrication in the interior only.

- Small volume, no noise.

Pneumatic Air Hoist Structure

1. Ergonomic control handle

Is ergonomically manufactured for minimum size and light weight. The rise and fall buttons are equipped with adjusting screws to adjust the rise and fall speeds according to actual needs. At the same time, the control handle has mounting holes on the back, which can be combined with fixtures for mounting.

2. Centrifugal brake

If the load is suddenly removed or suddenly and unexpectedly raised, the brake will open to prevent the wire rope from suddenly retracting.

The method to release the brake is to press and hold the descending button, empty the pressure in the cavity, then pull the wire rope downward (different loads, the force required is different), and hear the ‘ticking' sound, indicating that the brake is released.

3.Mute ball screw

The unique cycle design effectively prevents the wear and tear of the balls and prolongs the service life of the product.

4. Steel wire rope

As a consumable part, our steel wire rope is made of pure imported steel wire rope from Germany, which is twisted with special steel wire for lifting, effectively preventing from breakage and scattering of strands, and has the performance of anti-abrasion and anti-corrosion.

5.Steel shell

Sturdy all-steel shell, the cavity of the internal use of ultra-precision polishing technology, reducing friction, increasing the service life.

6.Engineering plastic reel

It is made of high performance special engineering plastics, once processed and moulded, with excellent wear-resisting performance.

7.Piston

As a wear part, our piston is injection moulded with special polyester compound, which has extremely low friction coefficient and wear resistance.

8.Suspension bracket

The suspension bracket can be directly suspended from the hook, or directly connected to the KBK sliding trolley, I-beam trolley and so on. The suspension bracket can also be dismantled according to customer’s needs, and the shell lugs can be used to connect with the components.

9. The pneumatic valve is made of aluminium alloy, which is used together with the control handle to achieve the function of ascending and descending.

Basic Types of Air Pneumatic Hoists

- Lifting capacity: 58kg-1100kg

- Built-in centrifugal brake function

- Air break protection function

- Overload protection function

- Infinitely variable speed function

- Adjustable button section function

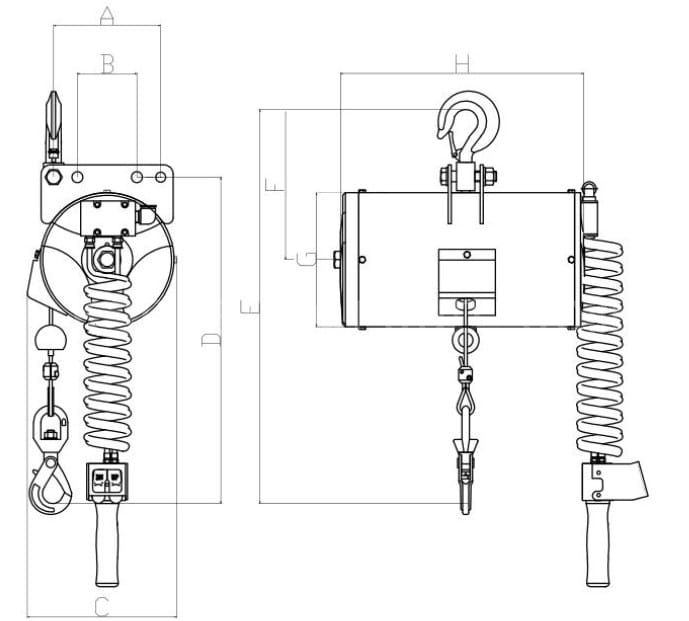

Dimensional Parameters for Single-Line Wire Rope Air Pneumatic Hoist

| A | B | C | D | E | F | G | L |

|---|---|---|---|---|---|---|---|

| 145 | / | 171 | 480 | 589 | 212 | 160 | 396 |

| 174 | 97 | 240 | 500 | 609 | 242 | 218 | 396 |

| 174 | 97 | 240 | 500 | 609 | 242 | 218 | 396 |

| 182 | 114 | 273 | 575 | 684 | 264 | 260 | 407 |

| 218 | 134 | 326 | 615 | 724 | 289 | 309 | 407 |

| 246 | 146 | 365 | 690 | 799 | 326 | 365 | 407 |

Standard ‘floating' mode, 400mm up and down

Maximum lifting weight is recommended to be around 80% of the rated load, exceeding this ratio will affect the floating performance.

Please contact us for special requirements.

Dimensions Parameters for Wire Rope Air Pneumatic Hoist with Sheave Block

The air pneumatic hoist with sheave block doubles the lifting capacity of the machine but halves the travelling distance.

| A | B | C | D | E | F | G | H |

|---|---|---|---|---|---|---|---|

| 182 | 114 | 273 | 695 | 805 | 264 | 260 | 407 |

| 218 | 134 | 326 | 745 | 855 | 286 | 309 | 407 |

| 246 | 146 | 365 | 809 | 920 | 326 | 365 | 407 |

Standard ‘floating' mode, 200mm up and down

Maximum lifting weight is recommended to be about 80% of the rated load, exceeding this ratio will affect the floating performance.

Please contact us for special requirements.

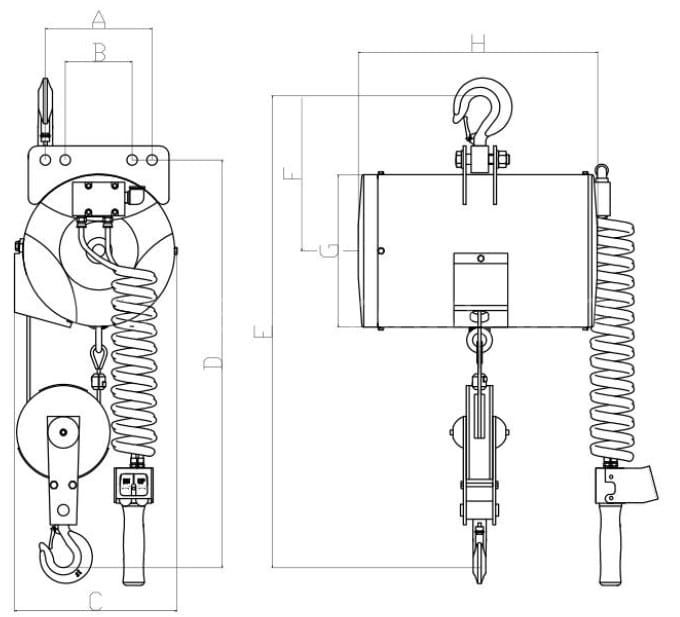

Dimensions Parameters for the Parallel Wire Rope Air Pneumatic Hoist

The parallel wire rope air pneumatic hoist lifts twice as much as a single-line wire rope air pneumatic hoist without any influence on the travelling distance.

| A | B | C | D | E | F | G | H |

|---|---|---|---|---|---|---|---|

| 486 | 64 | 570 | 575 | 684 | 282 | 260 | 407 |

| 571 | 93 | 670 | 615 | 724 | 289 | 309 | 407 |

| 630 | 79 | 756 | 690 | 799 | 326 | 365 | 407 |

Standard ‘floating' mode, 400mm up and down

Maximum lifting weight is recommended to be around 80% of the rated load, exceeding this ratio will affect the floating performance.

Please contact us for special requirements.

Dimensions Parameters for Parallel Wire Rope Air Pneumatic Hoist with Sheave Block

In order to increase the rated load, some of the products are connected in parallel with additional dynamic pulleys, which results in a lifting capacity four times that of the basic model.

| A | B | C | D | E | F | G | L |

|---|---|---|---|---|---|---|---|

| 486 | 64 | 570 | 695 | 805 | 282 | 260 | 407 |

| 571 | 93 | 670 | 745 | 855 | 289 | 309 | 407 |

| 630 | 79 | 756 | 809 | 920 | 326 | 365 | 407 |

Standard ‘floating' mode, 200mm up and down

Maximum lifting weight is recommended to be about 80% of the rated load, exceeding this ratio will affect the floating performance.

Please contact us if you have special requirements.

Air Driven Hoist Parameter Table:

| Rated Load (kg) | Maximum Stroke (mm) | Air Consumption (m³/h) | Number of Wire Rope Strands (n) | Maximum Lifting Speed (m/min) | Net Weight (kg) |

| Single-Line Wire Rope Air Hoist | |||||

| 58 | 1800 | 0.18 | 1 | 60 | 21 |

| 100 | 2000 | 0.2 | 1 | 35 | 27 |

| 100 | 2600 | 0.2 | 1 | 35 | 32 |

| 158 | 2000 | 0.21 | 1 | 25 | 47 |

| 228 | 2000 | 0.25 | 1 | 20 | 52 |

| 280 | 1900 | 0.3 | 1 | 15 | 62 |

| Wire Rope Air Hoist with Sheave Block | |||||

| 316 | 1000 | 0.21 | 2 | 12 | 51 |

| 456 | 1000 | 0.25 | 2 | 10 | 56 |

| 560 | 1900 | 0.3 | 2 | 7 | 69 |

| Parallel Wire Rope Air Hoist | |||||

| 316 | 2000 | 0.42 | 1 | 25 | 96 |

| 456 | 2000 | 0.5 | 1 | 20 | 106 |

| 560 | 1900 | 0.6 | 1 | 15 | 133 |

| Parallel Wire Rope Air Hoist with Sheave Block | |||||

| 630 | 1000 | 0.42 | 2 | 12 | 100 |

| 900 | 1000 | 0.5 | 2 | 10 | 110 |

| 1100 | 900 | 0.6 | 2 | 7 | 137 |

The actual lifting capacity is mainly determined by the input pressure, for every 0.1MPa decrease in input pressure, the actual lifting capacity decreases by 10%.

The maximum lifting weight is recommended to be about 80% of the rated load, exceeding this ratio will affect the floating performance.

Please contact us if you have special requirements.

Suspension Types Are as Follows:

Fixed Hook Type

I-Beam Trolley Type

Sliding Trolley Type

Advantages of Air Pneumatic Hoists Over Electric Hoists:

- Fast rising and falling speeds, usually 2-6 times faster than electric hoists

- ‘Floating' function, easy to achieve precise positioning

- Very high working system, 24 hours uninterrupted operation

- Compressed air as the driving force, non-sparking operation is safer

- Relying on the screw drive, smooth and jitter-free rising and falling, and can be infinitely variable speeds.

Get in Touch

- Free and fast quote for the product.

- Provide you our product catalog.

- Your local crane projects from our company.

- Become our agent and earn commission.

- Any questions, contact us.

.png?w=200&h=134)