- EQUIPMENT

-

special cranes

-

Garbage Grab Crane

-

Foundry Overhead Crane

-

Explosion-proof Overhead Crane

-

Tongs Overhead Crane

-

Overhead Crane with Carrier-beam

-

Electromagnetic Overhead Cranes

-

Diesel Hydraulic Straddle Carrier: Flexible Operation and Affordable Solution for Container Handling

-

Upper Spillway Gate Gantry Crane: Reliable Solution for Dam Gate Hoisting and Hydropower Station Operations

-

Harbour Portal Crane: Powerful and Intelligent Solutions for Efficient Port Handling

-

Coke Pot Crane for CDQ: Exceptional Heavy-Duty Red-Hot Coke Handling

-

Emergency Rescue Specialized Crane for Water-Rescue Simulation: Engineered for Lifesaving Training

-

Intelligent Grab Bucket Overhead Crane: Powerful, Precise and Unmanned Bulk Material Handling Solution

-

Custom Multi-Point Suspension Overhead Crane for Large-Span and Load-Sensitive Industrial Buildings

-

Electrolytic Copper Cranes: Specialized in Efficient Cathode Plate Tank Loading and Transfer

-

Nuclear Polar Cranes: Multi-Function Lifting Machinery For Nuclear Power Plants

-

-

Industry Crane

-

Industry Crane

-

Tundish Cranes

-

Slab Cranes

-

Scrap Cranes

-

Billet Cranes

-

Coil,Bar and Plate Handling Cranes

-

Cement And Precast Crane

-

Power Station Crane

-

Ladle Cranes

-

Paper Industry Cranes

-

Waste to Energy Cranes and Biomass Cranes

-

Tailored Overhead Cranes for Aerospace: High Precision, Efficience, Safety and Reliability

-

Anode Baking Multifunctional Cranes: Versatile, High-Temp Resistant & Smart-Controlled Must-Have for Electrolytic Aluminum Industry

-

Multifunctional Crane For Electrolytic Aluminum: Fulfills All Aluminum Electrolysis Processes, Boosts Plant Efficiency

-

Warehouse Stacker Crane for AS/RS: High-Efficiency, Reliable, Fully Automated Storage

-

Slab Handling Overhead Crane: Metallurgical-Grade Crane for Continuous Casting and Slab Yards

-

Anode Carbon Block Stacking Cranes: 6-Layer Stacking, A Lifting Solution for Carbon Plants’ Efficient Transfer

-

Quenching Crane for Heat Treatment: Process-Oriented Overhead Crane Solution

-

Safe & Stable Scrap Charging Overhead Crane for Metallurgical Feeding Operations

-

Forging Overhead Crane: Reliable Lifting Equipment for Heavy-Duty Forging Workshops

-

Mold Handling Crane for AAC Production Line: Reliable Engineered Fixed-Position Lifting Solution

-

-

Hoist & Winch Trolley

-

Casting Electric Wire Rope Hoist

-

European Model Electric Hoist

-

Explosion-proof Electric Hoist

-

Low-headroom Electric Hoist

-

Electric Chain Hoist

-

2 Types Explosion-Proof Electric Chain Hoists for Hazardous Zones: Gas & Dust Protection

-

2 Types Explosion-Proof Electric Wire Rope Hoists for Industrial Safety: Reliable Gas & Dust-Proof Solutions

-

Manual Hoists for Precision Lifting: Explore 3 Proven Types for Power-Free Operation

-

Air Pneumatic Hoists: 4 Specialized Designs for Precision, Safety, and Harsh Environments

-

HC Type Electric Hoist: Heavy-duty Wire Rope Hoist for Factory Heavy Lifting

-

-

CRANE Spreader

-

Crane Electromagnetic Lifting Magnets

-

Lifting Electromagnet for Turning and Side Hung

-

Lifting Electromagnet for Thick Plate

-

Specialized Electromagnet for Lifting Steel Plates

-

Lifting Electromagnets for Lifting Steel Plates

-

Lifting Electromagnet for Heavy Rail and Profiled Steel

-

Lifting Electromagnet for High Speed Wier(Coiled Bar)

-

Lifting Electromagnet for Rebar and Steel Pipe

-

Lifting Electromagnet for Bundled Rebar and Profiled Steel

-

Lifting Electromagnet for Billet, Girder Billet and Slab

-

Lifting Electromagnet for Steel Scraps

-

- Crane Spreader

- Crane Hook

- Crane Lifting Tongs and Clamps

-

Crane Electromagnetic Lifting Magnets

- CRANE PARTS

- Transfer Cart

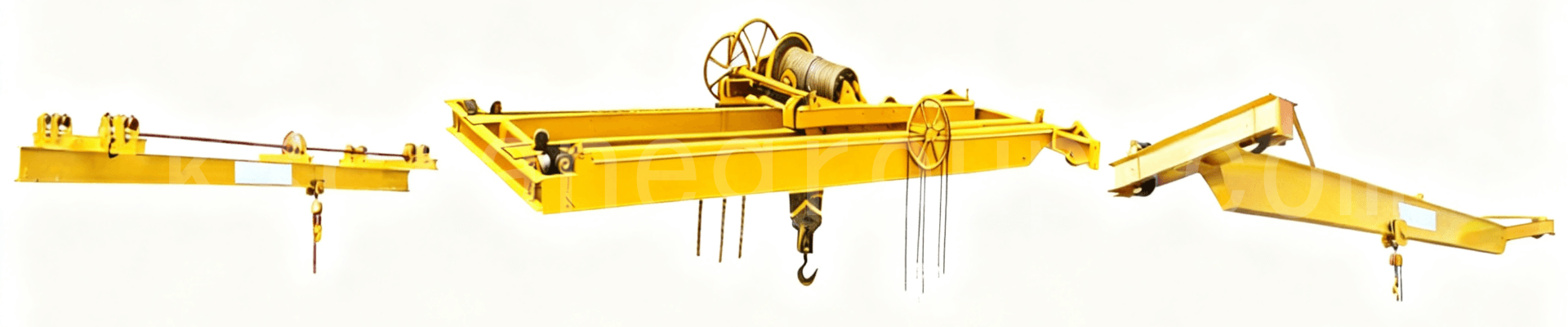

3 Types of Manual Overhead Crane: Power-Free Environments, A Low-Budget Lifting Solution

Manual overhead cranes are manually operated lifting devices suitable for environments without power sources, limited installation space, low budgets, or hazardous material storage. Featuring simple construction and easy maintenance, they are widely used in small workshops, warehouses, repair stations, and similar settings.

The core principle of manual single-girder bridge cranes involves mechanically transmitting human force to achieve precise lifting and transportation of heavy objects within three-dimensional space (vertical lifting, lateral movement, longitudinal movement). Essentially, they leverage simple mechanical transmission to amplify human strength, enabling lifting operations beyond the direct capabilities of conventional manual labor.

Manual Overhead Crane Types and Specifications

SL Manual Single Girder Overhead Crane

SL Manual Single-Girder Overhead Crane: A manual single-girder overhead crane denotes lifting equipment employing a single-girder structure and chain drive. This crane comprises a trolley travel mechanism, main girder, manual trolley, and manual hoisting mechanism, with its travel track mounted above the longitudinal rails.

Relevant Parameters:

- Lifting Capacity: 1–10 ton

- Lifting Height: 3–10m

- Working Class: A1–A3

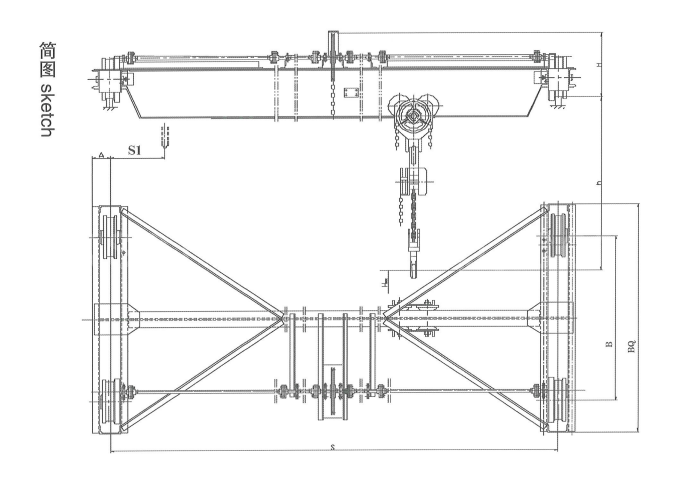

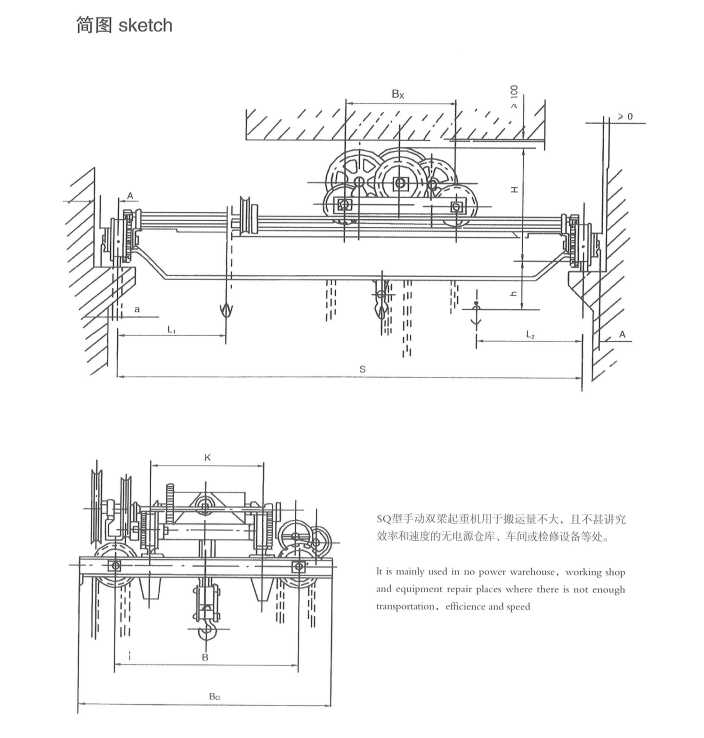

SQ Manual Double-Girder Bridge Crane

SQ Manual Double Girder: A manually operated bridge crane featuring a double-girder structure where the load is borne by a bridge frame composed of two main girders. The crane comprises a trolley travel mechanism, main girders, manual trolley, and manual hoisting mechanism, powered by manual pull transmission. The double-girder configuration offers enhanced stability and safety, making it suitable for long-term use.

Relevant Parameters:

- Lifting capacity: 5–20 ton

- Lifting height: 10m; 16m

- Span: 10–17m

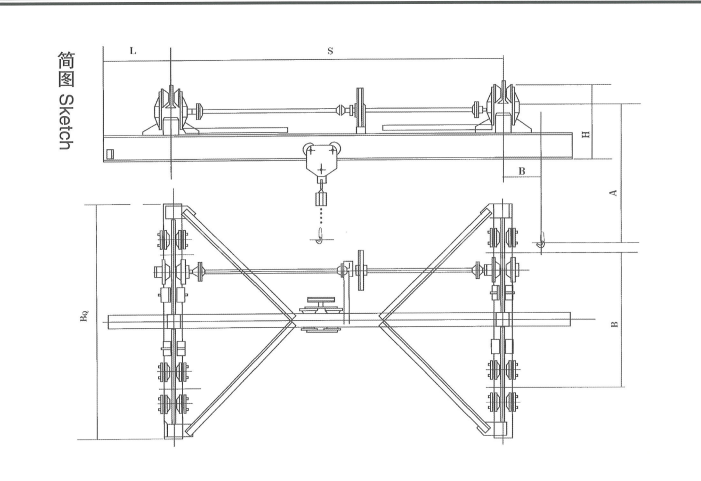

SLX Manual Single Girder Suspended Overhead Crane

SLX Manual Single-Girder Suspended: Suspended beneath roof structures or beams, this crane operates along I-beam tracks. Its principal components comprise the bridge frame, trolley travel mechanism, and manual monorail trolley. The entire crane traverses the lower flange of the I-beam track, with both hoisting and travel functions driven by manual chain hoists. This suspended manual bridge crane is suitable for applications where floor space is limited and track laying is impractical.

Relevant Parameters:

- Lifting capacity: 0.5–3 ton

- Span: 3–12m

- Lifting height: 2.5–12m

- Complementary hoist: HS-type manual chain hoist

Manual Overhead Crane Features and Advantages

Manual overhead cranes hold a significant position in lifting operations due to their numerous advantages. The following perspectives highlight the characteristics and benefits of manual overhead cranes.

Reliability

Manual overhead cranes rely on human power for lifting, eliminating the need for external electrical support. In areas with unstable power supply or during sudden power outages, operators can still lift cargo manually even without electricity, preventing operational downtime and economic losses. This prevents economic losses caused by operational halts due to power interruptions. In hazardous environments requiring explosion-proof measures, manual cranes eliminate certain safety hazards by lacking electrical systems, enabling safer and more stable operations.

Simple Structure

Designed for manual operation, manual overhead cranes feature lightweight and compact structures. Compared to EOT cranes, they eliminate numerous electrical and complex transmission components like motors, reducers, electrical cabinets, and cables. Lifting typically uses chain hoists and chain drives, while travel is driven by manual crank-operated gears, reducing the number of precision and failure-prone parts.

Simple Operation

Chain hoists utilize mechanical chain transmission powered by human effort, eliminating electrical operation barriers. Operators move alongside the load for intuitive distance control. Most tasks can be performed independently by a single operator, enabling shorter, more direct emergency procedures. For instance, during sudden jams or load loss, electrical faults can be addressed directly without emergency shutdowns or power cuts—mechanical components can be inspected based on the specific malfunction.

Cost-Effectiveness

Manual overhead cranes feature simple manufacturing, minimal consumables, and lower installation/commissioning costs, typically offering competitive pricing and superior economics. Operators require only brief training to become proficient, reducing training expenses.

Maintenance Convenience

Unlike electrically driven cranes requiring regular inspections of critical components like motors, resistors, and electrical cabinets, maintenance for manual overhead cranes primarily focuses on gear transmission mechanisms, chains, and manual brakes. This results in fewer maintenance components and faster servicing.

How to Select a Manual Overhead Crane

Manual overhead cranes offer distinct advantages but also present certain limitations in practical applications.

When selecting a manual crane, its reliance on human operation must be considered. For loads exceeding 5 tons, coordination between two or more operators is typically required, placing physical demands on the operators. If used frequently or over long distances, labor costs become a significant factor.

For small-scale, straightforward tasks, manual cranes may suffice; however, in large-scale, complex projects, electrically powered crane types are recommended as they may offer greater advantages.

In practical applications, comprehensive evaluation of factors such as the crane’s operating environment and budget is essential for selecting the appropriate crane. Whether manual overhead cranes or other electrically powered cranes, they all play vital roles in industrial production, providing reliable solutions for material handling and lifting tasks.

Industries Where Manual Overhead Cranes Are Applied

Manual overhead cranes are lightweight lifting equipment suitable for scenarios with smaller handling volumes. They are also ideal for environments where stable power supply voltage cannot be guaranteed or where strict efficiency requirements are not imposed. Manual overhead cranes can also be used in explosion-proof areas to reduce accidents caused by electrical components.

Below are real-world application scenarios for manual bridge cranes. Should you have any questions, our team welcomes your inquiries. We will recommend the most suitable lifting machinery for your industry.

Compressed Air Compressor Room

In the rich gas compressor plant, after the compressors boost the pressure of the rich gas, it is separated from non-condensable gases (such as methane and hydrogen). This process ultimately recovers high-value liquefied petroleum gas (LPG) and stable light hydrocarbons (gasoline components), enhancing the depth of petroleum processing and product yield, thereby delivering economic benefits. A double-girder manual overhead travelling crane is installed within the rich gas compressor plant for infrequent maintenance or new compressor installation.

Below are the parameters for the manual overhead travelling crane designed by our technical team according to the client’s plant requirements:

- Lifting capacity: 10 tonnes

- Span: 10.5m

- Lifting height: 12m

Advantages of manual overhead travelling cranes: Enriched gas typically contains high concentrations of hydrocarbon components, classifying it as a flammable and explosive gas. Manual overhead travelling cranes utilise mechanical chain-pull transmission, eliminating electrical sparks and ensuring high safety standards. This fundamentally removes electrical ignition sources, significantly simplifying safety management complexity. Manual bridge cranes require minimal maintenance, necessitating only periodic lubrication and inspection of tracks, wheels, chains, and gears, resulting in low upkeep costs.

Thermal Power Generation Enterprises

During coal transhipment operations, reliable lifting equipment is essential to ensure the efficient and stable conveyance of coal from storage areas to subsequent processing stages. Manual overhead travelling cranes are deployed in this phase to facilitate material transfer between coal storage silos and conveying apparatus, alongside the installation of transhipment equipment. The manual overhead travelling cranes selected for this project incorporate travel limit switches and buffer devices.

Below are the specifications of the manual overhead travelling crane designed by our technical team to meet the client’s facility requirements:

- Lifting capacity: 15 tonnes

- Span: 12 metres

- Lifting height: 15 metres

Advantages of manual overhead travelling cranes: The coal handling environment contains significant amounts of coal dust. The manual bridge crane employs mechanical chain-pull transmission, eliminating electrical sparks and ensuring high safety standards. This approach eradicates electrical ignition risks at source, significantly reducing safety management complexity. Furthermore, its maintenance is straightforward, requiring only periodic lubrication and inspection of tracks, wheels, chains, and gears. With low maintenance costs, it guarantees the continuous and stable operation of coal transfer and equipment maintenance across coal handling systems, transfer stations, sampling rooms, and other facilities.

Chemical Plant Wastewater Treatment

Within chemical plant industrial wastewater treatment facilities, domestic sewage treatment units, and processes involving chemical water filtration, desalination, and purification, manual overhead travelling cranes undertake the lifting and transportation of materials and components for water filtration and desalination equipment, as well as water purification systems. This ensures the smooth operation of water treatment processes, enabling compliant wastewater discharge and the provision of purified water to meet production requirements.

Specific Applications:

- Within industrial and domestic wastewater treatment facilities: Lifting mixing equipment, sludge scrapers, and other components within treatment tanks

- Within pump rooms: Transferring equipment such as butterfly valves to facilitate periodic dismantling and maintenance

- During chemical water filtration and desalination: Transporting filter cartridges, desalination resin tanks, and other components to operational areas for filter media replacement and internal component servicing, ensuring treated water meets subsequent production specifications

- In the purified water and wastewater treatment stages, assist in hoisting equipment or components such as chemical dosing tanks and filter plates for purified water filters. This facilitates equipment inspections and maintenance of dosing systems, ensuring efficient water purification processes and supplying clean production water to chemical plants.

Centrifugal Pump Maintenance and Replacement at Pumping Stations

In pump rooms, integrated pump houses, auxiliary pump house forepools, and fire pump rooms, manual overhead travelling cranes may be employed to hoist large equipment such as pumps and motors. Should a pump malfunction, the faulty unit can be swiftly lifted and transported to the maintenance area, while a standby pump is simultaneously hoisted into position. This ensures the stability of the water treatment system’s supply, meeting the chemical plant’s production water and firefighting water requirements.

Below are the specifications for the manual overhead travelling crane designed by our technical team to meet the client’s facility requirements:

- Crane configuration: 3-tonne manual single-girder suspended crane with a span of approximately 5 metres and a lifting height of 8 metres, equipped with a manual chain hoist and chain drive system.

- Operating Environment: The underground pump room is damp with corrosive vapours. Crane tracks require regular cleaning of oil residues to prevent slippage.

- Usage Frequency: Average annual lifting operations of 10-15 times, primarily for replacing worn pump impellers and motor maintenance.

- Special features: Manual operation ensures functionality during power outages or in confined spaces (e.g., sump chambers). The hoist incorporates overload protection to prevent chain breakage.

Advantages of manual overhead travelling cranes: Chemical plant wastewater treatment involves diverse equipment and components, with some operational environments being damp and containing corrosive gases. Manual overhead travelling cranes utilise mechanical transmission, featuring relatively simple structures that are less susceptible to dampness and corrosive gases, offering excellent stability. Furthermore, manual operation enables precise positioning control during lifting and handling, facilitating the installation of equipment such as filter tanks and chemical dosing tanks, as well as material transfer. This supports the efficient operation of water treatment systems, ensuring compliance with environmental standards and maintaining production water quality.

KUANGSHAN CRANE: China’s Top 3 Brand

As a globally oriented crane supplier, Mining Cranes has cultivated over two decades of expertise in the lifting sector, amassing extensive experience in crane manufacturing. From straightforward manual bridge cranes requiring no power supply to complex heavy-duty industrial cranes, all products undergo rigorous quality control and comprehensive testing to ensure reliable performance. Concurrently, our products have garnered highly favourable feedback from clients worldwide.

Established: In 2002

Certifications: ISO 9001 Quality Management System certified; compliant with GB/T 3811-2008 Crane Design Specifications; holds CE and other international certifications; possesses Special Equipment Manufacturing Licence.

Brand Advantages:

- Consistently ranked industry leader in production volume, sales volume, and market share for multiple consecutive years.

- Comprehensive service lifecycle and high cost-performance ratio

- One of China’s largest crane manufacturers with extensive global project experience

- Large-scale operation featuring diverse processing and testing equipment across a 680,000 square metre site

Applicable Industries: Aerospace, automotive, chemical, railways, steel, machinery manufacturing, ports, construction, waste incineration, and numerous other sectors.

Project Experience: Involved in multinational projects including Lahore Metro Rail in Pakistan, overhaul of high-power locomotives for Xi’an Railway Bureau, and the Yishan Steel Project in Vietnam. Delivered reliable products and services to tens of thousands of customers across 122 countries worldwide.

Bolstered by brand strength, extensive industry applications, and rich multinational project experience, KUANGSHAN CRANE also excels in the manual bridge crane sector. Below are case studies showcasing Mining Cranes’ export of manual bridge cranes.

4 Sets Of Sl-Type Manual Suspended Single-Girder Overhead Travelling Cranes Exported To Pakistan

In September 2014, KUANGSHAN CRANE successfully exported four sets of SL-type manual suspended single-girder overhead travelling cranes to Pakistan, providing reliable lifting solutions for local operations.

The crane’s fundamental technical specifications are as follows:

- Lifting capacity: 2 ton

- Lifting height: 4.5m

- Span: 5m

- Contract price: $2100/sets

Featuring manual operation, these cranes enable uninterrupted lifting operations even in environments without power supply or where electricity is unreliable.

Prior to placing the order, the client visited our factory, gaining a more intuitive and thorough understanding of the products. Suspended overhead cranes require no floor space but necessitate adequate roof load-bearing capacity in workshops. They conserve space while ensuring stable operation.

Following production, our dispatch department meticulously packaged the cranes alongside manual chain trolleys. The equipment was then transported safely and efficiently to Pakistan, guaranteeing its intact arrival and prompt operational readiness.

Should you wish to learn more about our mining crane projects, or require procurement, customisation, or technical consultation for manual overhead cranes, please do not hesitate to contact us. Our team possesses professional technical expertise and extensive industry experience, enabling us to provide tailored solutions and attentive service. We look forward to discussing potential collaboration with you.

Get in Touch

- Free and fast quote for the product.

- Provide you our product catalog.

- Your local crane projects from our company.

- Become our agent and earn commission.

- Any questions, contact us.

.png?w=200&h=134)