- EQUIPMENT

-

special cranes

-

Garbage Grab Crane

-

Foundry Overhead Crane

-

Explosion-proof Overhead Crane

-

Tongs Overhead Crane

-

Overhead Crane with Carrier-beam

-

Electromagnetic Overhead Cranes

-

Diesel Hydraulic Straddle Carrier: Flexible Operation and Affordable Solution for Container Handling

-

Upper Spillway Gate Gantry Crane: Reliable Solution for Dam Gate Hoisting and Hydropower Station Operations

-

Harbour Portal Crane: Powerful and Intelligent Solutions for Efficient Port Handling

-

Coke Pot Crane for CDQ: Exceptional Heavy-Duty Red-Hot Coke Handling

-

Emergency Rescue Specialized Crane for Water-Rescue Simulation: Engineered for Lifesaving Training

-

Intelligent Grab Bucket Overhead Crane: Powerful, Precise and Unmanned Bulk Material Handling Solution

-

Custom Multi-Point Suspension Overhead Crane for Large-Span and Load-Sensitive Industrial Buildings

-

Electrolytic Copper Cranes: Specialized in Efficient Cathode Plate Tank Loading and Transfer

-

Nuclear Polar Cranes: Multi-Function Lifting Machinery For Nuclear Power Plants

-

-

Industry Crane

-

Industry Crane

-

Tundish Cranes

-

Slab Cranes

-

Scrap Cranes

-

Billet Cranes

-

Coil,Bar and Plate Handling Cranes

-

Cement And Precast Crane

-

Power Station Crane

-

Ladle Cranes

-

Paper Industry Cranes

-

Waste to Energy Cranes and Biomass Cranes

-

Tailored Overhead Cranes for Aerospace: High Precision, Efficience, Safety and Reliability

-

Anode Baking Multifunctional Cranes: Versatile, High-Temp Resistant & Smart-Controlled Must-Have for Electrolytic Aluminum Industry

-

Multifunctional Crane For Electrolytic Aluminum: Fulfills All Aluminum Electrolysis Processes, Boosts Plant Efficiency

-

Warehouse Stacker Crane for AS/RS: High-Efficiency, Reliable, Fully Automated Storage

-

Slab Handling Overhead Crane: Metallurgical-Grade Crane for Continuous Casting and Slab Yards

-

Anode Carbon Block Stacking Cranes: 6-Layer Stacking, A Lifting Solution for Carbon Plants’ Efficient Transfer

-

Quenching Crane for Heat Treatment: Process-Oriented Overhead Crane Solution

-

Safe & Stable Scrap Charging Overhead Crane for Metallurgical Feeding Operations

-

Forging Overhead Crane: Reliable Lifting Equipment for Heavy-Duty Forging Workshops

-

Mold Handling Crane for AAC Production Line: Reliable Engineered Fixed-Position Lifting Solution

-

-

Hoist & Winch Trolley

-

Casting Electric Wire Rope Hoist

-

European Model Electric Hoist

-

Explosion-proof Electric Hoist

-

Low-headroom Electric Hoist

-

Electric Chain Hoist

-

2 Types Explosion-Proof Electric Chain Hoists for Hazardous Zones: Gas & Dust Protection

-

2 Types Explosion-Proof Electric Wire Rope Hoists for Industrial Safety: Reliable Gas & Dust-Proof Solutions

-

Manual Hoists for Precision Lifting: Explore 3 Proven Types for Power-Free Operation

-

Air Pneumatic Hoists: 4 Specialized Designs for Precision, Safety, and Harsh Environments

-

HC Type Electric Hoist: Heavy-duty Wire Rope Hoist for Factory Heavy Lifting

-

-

CRANE Spreader

-

Crane Electromagnetic Lifting Magnets

-

Lifting Electromagnet for Turning and Side Hung

-

Lifting Electromagnet for Thick Plate

-

Specialized Electromagnet for Lifting Steel Plates

-

Lifting Electromagnets for Lifting Steel Plates

-

Lifting Electromagnet for Heavy Rail and Profiled Steel

-

Lifting Electromagnet for High Speed Wier(Coiled Bar)

-

Lifting Electromagnet for Rebar and Steel Pipe

-

Lifting Electromagnet for Bundled Rebar and Profiled Steel

-

Lifting Electromagnet for Billet, Girder Billet and Slab

-

Lifting Electromagnet for Steel Scraps

-

- Crane Spreader

- Crane Hook

- Crane Lifting Tongs and Clamps

-

Crane Electromagnetic Lifting Magnets

- CRANE PARTS

- Transfer Cart

10 Ton Gantry Crane Buying Guide: Types, Specifications, Price Insights, and Applications

Table of Contents

The 10 ton gantry crane is highly common in medium to heavy-duty workshops, precast yards, docks, or construction sites. It combines flexibility with load-bearing capacity—offering both portable, lightweight gantry cranes and robust double-girder or semi-gantry cranes suitable for high-intensity operations. This article will detail the types, parameters, and typical case studies to assist procurement, engineering, and equipment management personnel in making quick decisions and comparisons.

Types of 10 Ton Gantry Crane

10 Ton Single Girder Gantry Crane with Electric Hoist

A common light to medium-duty gantry crane, equipped with an electric hoist, suitable for routine material handling in workshops. It offers flexible specifications and relatively economical cost.

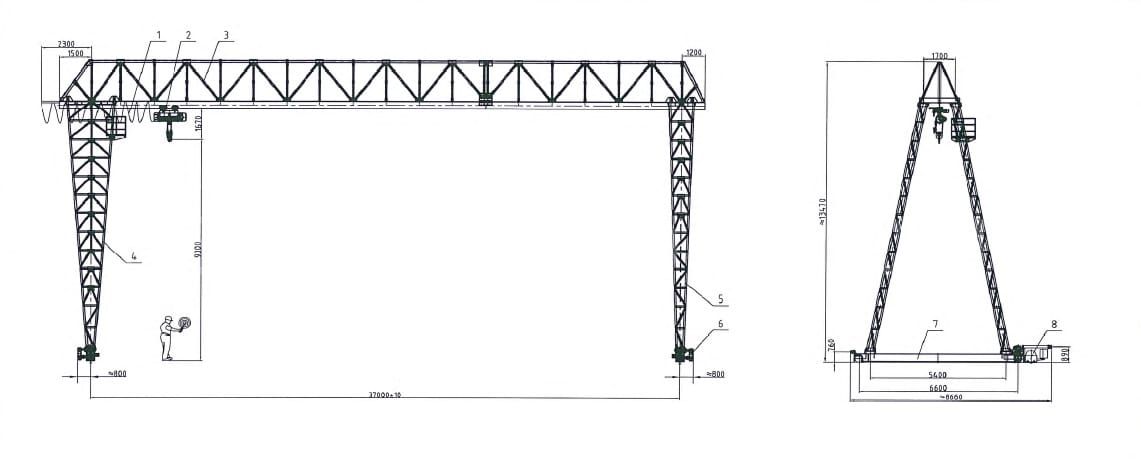

10 Ton Truss Type Single Girder Gantry Crane with Electric Hoist

The truss beam reduces self-weight and material usage through a spatial truss structure, ideal for outdoor or wind-loaded environments.

A semi-gantry design with one side fixed to a wall, saving space and suitable for operations along the edge of a factory. Semi-gantry cranes are widely used within the 10-ton range.

10 Ton A-type Double Girder Gantry Crane with Hook

The A-type structure with double girders provides greater rigidity and safety margin, suitable for high lifting heights and frequent heavy-load operations.

10 Ton U-type Double Girder Gantry Crane with Hook

The U-type gantry typically offers advantages in side frame profile or maintenance access. It is structurally similar to the A-type double girder but may be more flexible in layout and site accessibility.

10 Ton L-type Single Girder Gantry Crane with Hook

The L-type usually refers to a single-girder crane with a single leg or specific leg design, suitable for scenarios with limited headroom or budget constraints. It has lower load capacity and rigidity compared to double-girder cranes but is more cost-effective.

10 Ton Portable Gantry Crane

Designed for easy assembly and mobility, it is ideal for temporary conditions or multi-point operations. Portable gantry cranes are very common in light to medium load scenarios, with a few available in the 10-ton range.

These types cover a range of needs from portable to heavy-duty, allowing users to choose based on site and load requirements.

10 Ton Gantry Crane Parameters

Below is a table of key parameters for common 10-ton gantry cranes, based on market standards and supplier data for easy comparison:

| Products | Span/m | Lifting Height/m | Working Duty | Power Supply Voltage |

|---|---|---|---|---|

| 10 ton A type double girder gantry crane with hook | 18-35 | 10-11 | A5 | 3-Phase A.C. 50Hz 380V |

| 10 ton U type double girder gantry crane with hook | 18-35 | 11.5 | A5 | 3-Phase A.C. 50Hz 380V |

| 10 ton L type single girder gantry crane with hook | 18-35 | 10-11 | A5 | 3-Phase A.C. 50Hz 380V |

| 10 ton truss type single girder gantry crane with electric hoist | 12-30 | 6-9 | A3 | 3-Phase A.C. 50Hz 380V |

| 10 ton single girder gantry crane with electric hoist | 12-30 | 6-9 | A3 | 3-Phase A.C. 50Hz 380V |

Note: The above span, lifting height, and working duty are typical design ranges. Actual projects can be optimized or customized based on operating conditions (usage frequency, environment, lifting height requirements, etc.).

10 Ton Gantry Crane Price

Prices are influenced by capacity, span, lifting height, and working duty. The table below lists quotes for selected products:

| Products | Capacity | Span | Lifting Height | Working Duty | Price/USD |

|---|---|---|---|---|---|

| Single girder gantry crane with hoist | 10 ton | 23m | 6m | A3 | $1,800 |

| Single girder gantry crane with hoist | 10 ton | 25m | 6m | A3 | $1,853 |

| Single girder gantry crane with hoist | 10 ton | 28m | 6.5m | A3 | $2,114 |

| Single girder gantry crane with hoist | 10 ton | 32m | 6m | A3 | $2,767 |

| Truss type single girder gantry crane with hoist | 10 ton | 37m | 9m | A3 | $43,957 |

| Single girder semi gantry crane | 10 ton | 9.5m | 9m | A3 | $563 |

| FEM Standard semi gantry crane | 10 ton | 14m | 8m | A5 | $1,354 |

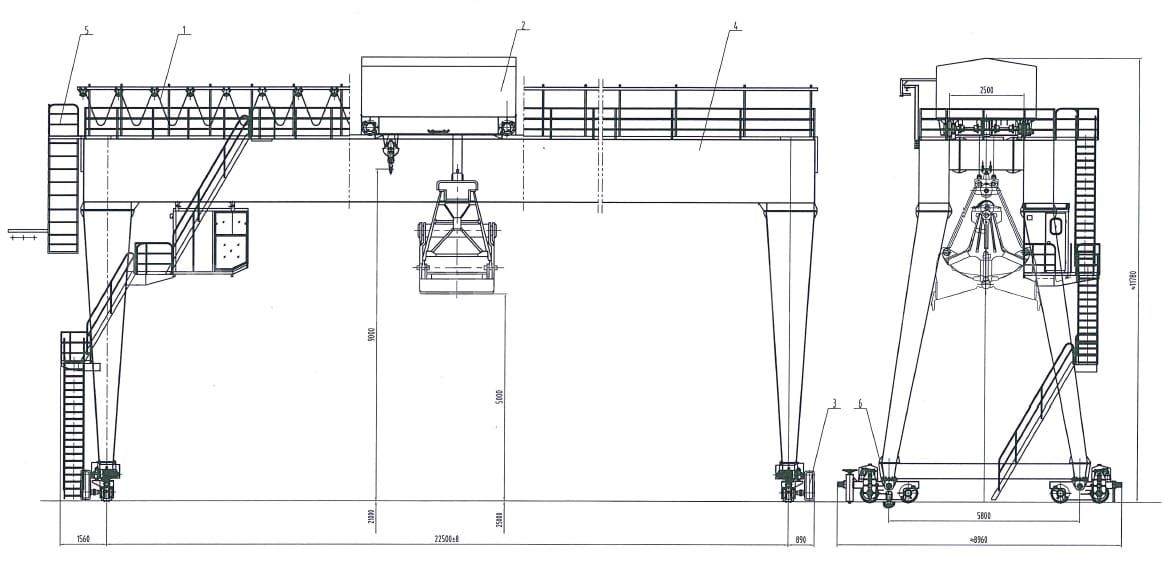

| Double girder gantry crane with grab | 10/5 ton | 22.5m | 30m | A7 | $92,643 |

Note: Prices given in the table are for general reference only; actual prices may vary depending on specific customization or additional features required for the project.

The price range for 10-ton gantry cranes is wide, depending on single/double girder, span, lifting height, additional configurations, anti-corrosion/explosion-proof features, grab/hoist type, control method, and brand. Kuangshan Crane, a leading Chinese crane manufacturer, offers 24-hour online support from professional engineers. Contact Kuangshan Crane for accurate quotes.

10 Ton Gantry Crane Applications

10-ton gantry cranes are suitable for various industrial environments, including:

- Manufacturing workshops: For lifting heavy components on assembly lines, such as in automotive or machinery manufacturing.

- Warehouses and logistics centers: Handling cargo loading/unloading to improve storage efficiency.

- Construction sites: Temporary lifting of construction materials like steel bars or concrete components.

- Ports and docks: Assisting with cargo loading, suitable for humid and dusty environments.

- Mines and metallurgical plants: Handling ores or metal materials, enduring high temperatures or harsh conditions.

- Precast yards and bridge engineering: Supporting large-span operations like precast beam handling.

- Steel/metal processing plants, waste handling, and recycling yards: Grab gantry cranes for bulk material handling.

These applications vary significantly in working duty and selection: outdoor grab operations or dusty/humid conditions require higher working duties (e.g., A7, M7) with anti-corrosion, moisture-proof, and temperature-resistant designs; routine indoor handling can use A3–A5.

Kuangshan Crane Case Studies

Metal Company Procurement of Hot Rough Rolling Gantry Crane

The project involves replacing an old grab gantry crane in a humid, dusty environment with temperatures ranging from -5 to 45°C. This case involves high-intensity grab operations (A7), with stringent requirements for grab performance, sealing/dust-proofing, and electrical protection.

Product Parameters

- Type: double girder gantry crane with grab

- Capacity: 10/5 ton (main hook 10 t including grab weight, auxiliary hook 5 t)

- Span: 22.5 m

- Lifting height: 30 m

- Lifting speed: 12.15 m/min

- Traveling speed: 40 m/min (crane), 45 m/min (trolley)

- Working duty: A7 (main hook M7 / auxiliary hook M5)

- Control method: Cabin control

Construction Company New Factory Lifting Equipment Procurement

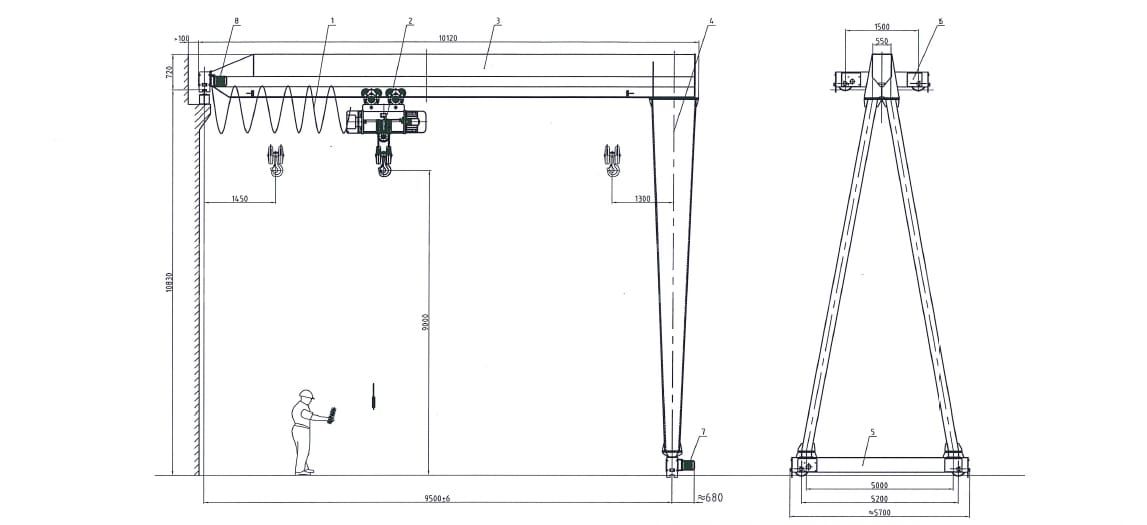

The project includes a gantry beam lifter and a semi-gantry crane. The 10-ton semi-gantry crane is used for light to medium loads inside the factory, adopting a semi-gantry design to save track/foundation costs. A3 working duty is suitable for daily production line handling. The semi-gantry crane consists of a steel gantry frame, crane traveling mechanism, electric hoist, and electrical control system.

Product Parameters

- Type: single girder semi gantry crane

- Capacity: 10 ton

- Span: 9.5 m

- Lifting height: 9 m

- Lifting speed: 7 m/min

- Traveling speed: 20 m/min (crane)

- Working duty: A3

- Control method: Remote control

China Railway Tenth Bureau Xintai Expressway Project

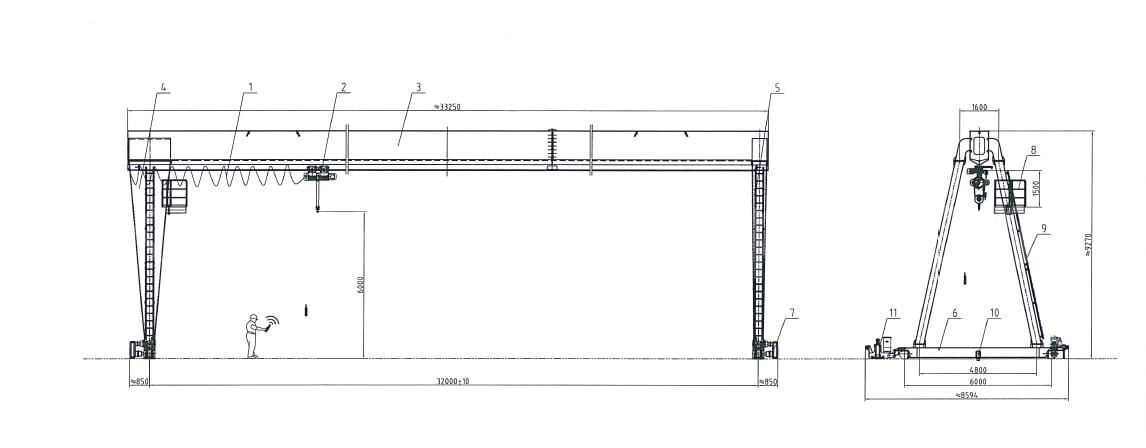

This project is a key section of Shandong's expressway network, spanning 157.548 km, covering roadbed, bridges, culverts, and pavement works. The procurement includes 2 beam-lifting gantry cranes and 8 electric hoist gantry cranes, 4 of which are 10-ton.

Product Parameters

- Type: single girder gantry crane with hoist

- Capacity: 10 ton

- Span: 23/25/28/32 m

- Lifting height: 6/6.5m

- Working duty: A3

New Material Company Phase I Construction Project

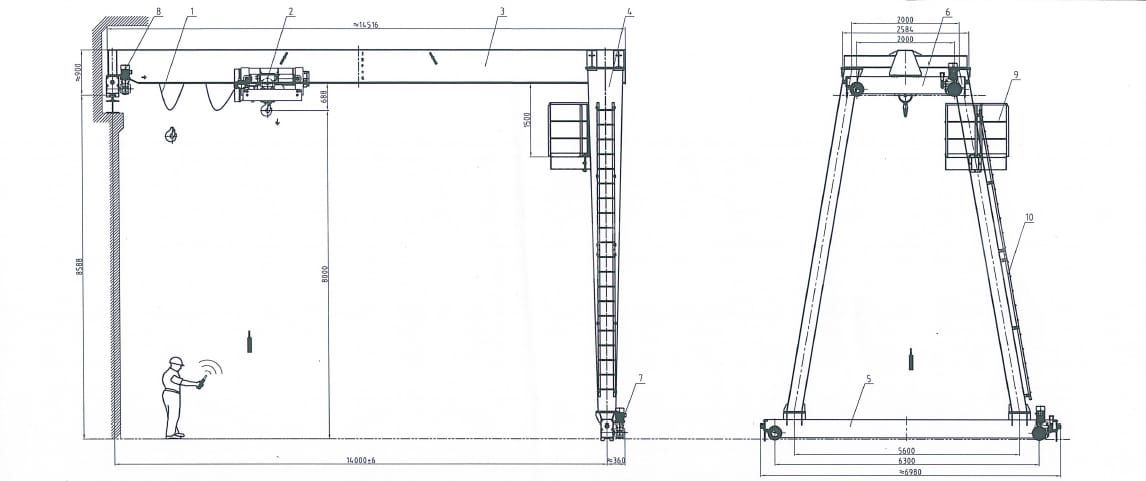

The project includes galvanizing and multi-functional coating lines, producing 300,000 tons of high-grade coated plates and 1 million tons of galvanized strips annually. High-production projects typically adopt FEM standards for durability and repeatability, with A5 suitable for higher-frequency processing environments.

Product Parameters

- Type: FEM Standard semi gantry crane

- Capacity: 10 ton

- Span: 14 m

- Lifting height: 8 m

- Lifting speed: 5/0.8 m/min

- Traveling speed: 3-30 m/min (crane), 2-20 m/min (trolley)

- Working duty: A5

- Control method: Remote control

Precast Yard Beam and Slab Construction Project

To meet precast beam and slab construction needs, a 37-meter span 10-ton gantry crane was installed in the Baimitang precast yard for formwork assembly/disassembly and concrete pouring. This project uses a truss-type gantry crane with cable drum power supply. Large spans (37 m) and outdoor conditions require consideration of truss self-weight, wind loads, long-term deformation, and track stability.

Product Parameters

- Type: truss type single girder gantry crane with hoist

- Capacity: 10 ton

- Span: 37 m

- Lifting height: 9 m

- Lifting speed: 7/0.7 m/min

- Traveling speed: 22 m/min (crane), 20 m/min (trolley)

- Working duty: A3

- Control method: Remote control

Factors to Consider Before Buying a 10 Ton Gantry Crane

When purchasing, businesses should evaluate:

- Working Environment: Indoor/outdoor, temperature, humidity, explosive environment.

- Lifting Frequency: Occasional lifting vs. continuous heavy-duty use.

- Span & Lifting Height: To match site layout.

- Mobility Needs: Rail travelling vs. portable mobile gantry crane design.

- Safety Standards: CE, ISO, FEM, CMAA compliance.

- After-Sales Support: Availability of spare parts, installation, and maintenance services.

- Budget: Balance between cost and long-term durability.

Top Manufacturers & Suppliers of 10 Ton Gantry Cranes

- Kuangshan Crane (China): Leading global supplier with strong export record.

- Dafang Crane (China): Known for custom gantry and overhead cranes.

- Weihua Group (China): One of the largest crane manufacturers in Asia.

- Spanco (USA): Significant presence in the light material handling market.

- GH Cranes (Spain): Popular in Europe and Latin America.

When sourcing internationally, Chinese manufacturers dominate the mid-range market due to cost advantage, while European and American suppliers offer premium automated systems.

Installation and Maintenance of 10 Ton Gantry Crane

- Foundation: Requires reinforced ground track or floor.

- Installation: Can be completed within days by professional engineers.

- Testing: Load testing is required before operation.

- Maintenance: Regular lubrication of moving parts. Inspection of hoist, wire rope, and brakes. Electrical system check-up. Replacement of worn-out wheels and rails.

Proper installation and preventive maintenance will ensure 10–20 years of reliable service life.

Conclusion

The 10 ton gantry crane is one of the most versatile and cost-effective lifting solutions for medium-duty industrial applications. Its flexibility, moderate capacity, and relatively lower cost compared to higher-capacity cranes make it a popular choice in global markets.

When choosing the right model, consider type (single girder, double girder, mobile, semi-gantry), technical specifications, budget, and supplier reputation. With proper installation, operation, and maintenance, a 10 ton gantry crane can significantly improve productivity and safety in your workplace.

Do you like what we do?Share it

.png?w=200&h=134)