- EQUIPMENT

-

special cranes

-

Garbage Grab Crane

-

Foundry Overhead Crane

-

Explosion-proof Overhead Crane

-

Tongs Overhead Crane

-

Overhead Crane with Carrier-beam

-

Electromagnetic Overhead Cranes

-

Diesel Hydraulic Straddle Carrier: Flexible Operation and Affordable Solution for Container Handling

-

Upper Spillway Gate Gantry Crane: Reliable Solution for Dam Gate Hoisting and Hydropower Station Operations

-

Harbour Portal Crane: Powerful and Intelligent Solutions for Efficient Port Handling

-

Coke Pot Crane for CDQ: Exceptional Heavy-Duty Red-Hot Coke Handling

-

Emergency Rescue Specialized Crane for Water-Rescue Simulation: Engineered for Lifesaving Training

-

Intelligent Grab Bucket Overhead Crane: Powerful, Precise and Unmanned Bulk Material Handling Solution

-

Custom Multi-Point Suspension Overhead Crane for Large-Span and Load-Sensitive Industrial Buildings

-

Electrolytic Copper Cranes: Specialized in Efficient Cathode Plate Tank Loading and Transfer

-

Nuclear Polar Cranes: Multi-Function Lifting Machinery For Nuclear Power Plants

-

-

Industry Crane

-

Industry Crane

-

Tundish Cranes

-

Slab Cranes

-

Scrap Cranes

-

Billet Cranes

-

Coil,Bar and Plate Handling Cranes

-

Cement And Precast Crane

-

Power Station Crane

-

Ladle Cranes

-

Paper Industry Cranes

-

Waste to Energy Cranes and Biomass Cranes

-

Tailored Overhead Cranes for Aerospace: High Precision, Efficience, Safety and Reliability

-

Anode Baking Multifunctional Cranes: Versatile, High-Temp Resistant & Smart-Controlled Must-Have for Electrolytic Aluminum Industry

-

Multifunctional Crane For Electrolytic Aluminum: Fulfills All Aluminum Electrolysis Processes, Boosts Plant Efficiency

-

Warehouse Stacker Crane for AS/RS: High-Efficiency, Reliable, Fully Automated Storage

-

Slab Handling Overhead Crane: Metallurgical-Grade Crane for Continuous Casting and Slab Yards

-

Anode Carbon Block Stacking Cranes: 6-Layer Stacking, A Lifting Solution for Carbon Plants’ Efficient Transfer

-

Quenching Crane for Heat Treatment: Process-Oriented Overhead Crane Solution

-

Safe & Stable Scrap Charging Overhead Crane for Metallurgical Feeding Operations

-

Forging Overhead Crane: Reliable Lifting Equipment for Heavy-Duty Forging Workshops

-

Mold Handling Crane for AAC Production Line: Reliable Engineered Fixed-Position Lifting Solution

-

-

Hoist & Winch Trolley

-

Casting Electric Wire Rope Hoist

-

European Model Electric Hoist

-

Explosion-proof Electric Hoist

-

Low-headroom Electric Hoist

-

Electric Chain Hoist

-

2 Types Explosion-Proof Electric Chain Hoists for Hazardous Zones: Gas & Dust Protection

-

2 Types Explosion-Proof Electric Wire Rope Hoists for Industrial Safety: Reliable Gas & Dust-Proof Solutions

-

Manual Hoists for Precision Lifting: Explore 3 Proven Types for Power-Free Operation

-

Air Pneumatic Hoists: 4 Specialized Designs for Precision, Safety, and Harsh Environments

-

HC Type Electric Hoist: Heavy-duty Wire Rope Hoist for Factory Heavy Lifting

-

-

CRANE Spreader

-

Crane Electromagnetic Lifting Magnets

-

Lifting Electromagnet for Turning and Side Hung

-

Lifting Electromagnet for Thick Plate

-

Specialized Electromagnet for Lifting Steel Plates

-

Lifting Electromagnets for Lifting Steel Plates

-

Lifting Electromagnet for Heavy Rail and Profiled Steel

-

Lifting Electromagnet for High Speed Wier(Coiled Bar)

-

Lifting Electromagnet for Rebar and Steel Pipe

-

Lifting Electromagnet for Bundled Rebar and Profiled Steel

-

Lifting Electromagnet for Billet, Girder Billet and Slab

-

Lifting Electromagnet for Steel Scraps

-

- Crane Spreader

- Crane Hook

- Crane Lifting Tongs and Clamps

-

Crane Electromagnetic Lifting Magnets

- CRANE PARTS

- Transfer Cart

Heavy Duty Gantry Crane for High-Duty Class & Relentless Continuous Load Applications

Table of Contents

A heavy duty gantry crane is a type of gantry crane specifically engineered for very large lifting capacities, high duty classes, high operating cycles, and harsh working environments. It is widely used in port yards, steel and metallurgical plants, bridge construction, shipyards, energy equipment manufacturing, and other heavy industrial sectors.

If your project involves both high operating frequency and high load utilization, the crane required is no longer a standard gantry crane, but a heavy duty gantry crane in the true engineering sense.

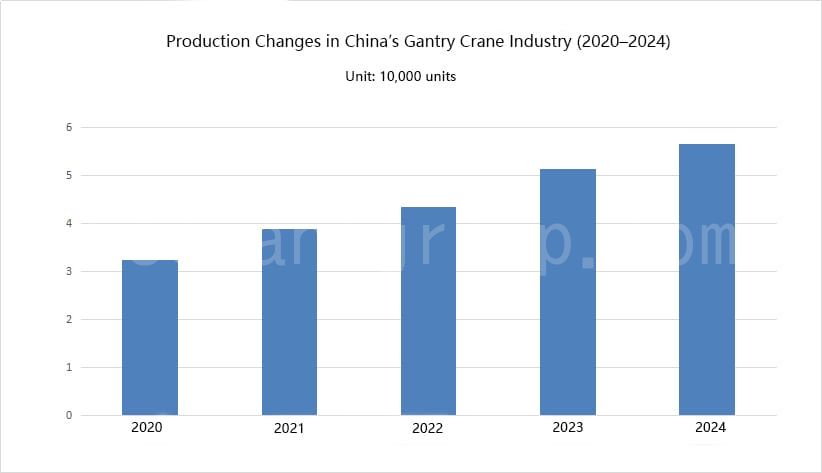

Gantry Crane Market Analysis

Entering 2025, driven by increased global infrastructure investment, demand for heavy duty gantry cranes continues to grow strongly. According to data from China Report Hall, the global gantry crane market reached approximately RMB 14.5 billion in 2023. The market is expected to grow at a compound annual growth rate (CAGR) of about 5.5% by 2025, and is projected to reach RMB 24 billion by 2030.

Key growth drivers include infrastructure development, industrial automation, and intelligent manufacturing, particularly in ports, infrastructure projects, and heavy manufacturing industries.

What Is a True Heavy Duty Gantry Crane?

A Heavy Duty Gantry Crane adopts a gantry frame structure with supporting legs, operating on ground rails or rubber tires, and does not rely on building runway beams or roof structures for load-bearing capacity. It is particularly suitable for:

- Extra-large span operations

- Outdoor, temporary, or semi-open working environments

- High-load, long-term, high-cycle applications

When projects involve extremely heavy components, very high usage frequency, or structural limitations of buildings, heavy duty gantry cranes often provide higher safety and superior life-cycle cost advantages.

The Essence of “Heavy Duty”: Duty Class, Not Rated Capacity

A common misconception in engineering practice is: Higher capacity equals a heavy-duty crane. In fact, according to GB/T 3811-2008 – Design Rules for Cranes, whether a crane qualifies as “heavy duty” is determined not by its rated lifting capacity, but by its overall duty class (A-class).

1. How Is Duty Class Defined?

GB/T 3811-2008 clearly defines:

Overall crane duty class = Utilization class (U) + Load spectrum class (Q)

In other words, duty class is not a subjective judgment, but the result of two quantifiable engineering parameters.

2. Utilization Class (U): “How Long and How Frequently the Crane Is Used”

The utilization class reflects the total number of operating cycles (CT) over the crane's designed service life.

- One operating cycle: lifting → traveling/hoisting → unloading → idle time → preparation for the next lift

| Utilization Class | Total Operating Cycles (CT) | Usage Frequency |

|---|---|---|

| U0 | CT≤1.60X104 | Very infrequent |

| U1 | 1.60X104<CT≤3.20X104 | Very infrequent |

| U2 | 3.20X104<CT≤6.30X104 | Very infrequent |

| U3 | 6.30X104<CT≤1.25X105 | Very infrequent |

| U4 | 1.25X105<CT≤2.50X105 | Infrequent |

| U5 | 2.50X105<CT≤5.00X105 | Moderately frequent |

| U6 | 5.00X105<CT≤1.00X106 | Frequent |

| U7 | 1.00X106<CT≤2.00X106 | Very frequent |

| U8 | 2.00X106<CT≤4.00X106 | Extremely frequent |

| U9 | 4.00X106<CT | Extremely frequent |

Port cranes, metallurgical cranes, slag handling cranes, shield tunneling cranes, and RMG cranes typically fall into U7 or higher.

3. Load Spectrum Class (Q): “How Heavy Each Lift Is”

The load spectrum class describes the relationship between actual lifted loads and rated capacity, expressed by the load spectrum coefficient (KP).

| Load Class | KP Range | Description |

|---|---|---|

| Q1 | KP≤0.125 | Rarely lifts rated load; mostly light loads |

| Q2 | 0.125<KP≤0.250 | Occasional rated loads; mostly medium loads |

| Q3 | 0.250<KP≤0.500 | Frequent heavy loads; occasional rated loads |

| Q4 | 0.500<KP≤1.000 | Frequently operates near rated capacity |

Metallurgical gantry cranes, container gantry cranes, and heavy double-girder gantry cranes typically fall into Q3–Q4.

4. Determining “Heavy Duty” from U + Q

GB/T 3811-2008 classifies crane duty into A1–A8 based on combinations of U and Q.

| Load Class | KP Range | Utilization Class | |||||||||

| U0 | U1 | U2 | U3 | U4 | U5 | U6 | U7 | U8 | U9 | ||

| Q1 | KP≤0.125 | A1 | A1 | A1 | A2 | A3 | A4 | A5 | A6 | A7 | A8 |

| Q2 | 0.125<KP≤0.250 | A1 | A1 | A2 | A3 | A4 | A5 | A6 | A7 | A8 | A8 |

| Q3 | 0.250<KP≤0.500 | A1 | A2 | A3 | A4 | A5 | A6 | A7 | A8 | A8 | A8 |

| Q4 | 0.500<KP≤1.000 | A2 | A3 | A4 | A5 | A6 | A7 | A8 | A8 | A8 | A8 |

In engineering practice, the general interpretation is:

- A5: Entry level for engineering gantry cranes

- A6: Common heavy-duty applications

- A7: True heavy-duty gantry cranes

- A8: Extremely heavy-duty, continuous full-load operation

Only cranes with A6 or above can reasonably be defined as heavy duty gantry cranes.

This is why professional crane selection starts from U and Q, rather than simply increasing rated capacity.

GB/T vs. FEM vs. ISO Duty Class Correlation

Although expressed differently, GB/T, FEM, and ISO standards share the same core logic:

- GB/T 3811: Utilization class (U) + Load class (Q)

- FEM 1.001: Utilization + Load spectrum → Group

- ISO 4301: Load spectrum + Class

All are fundamentally based on fatigue life and load utilization.

| GB/T Class | FEM Class | ISO Class | Engineering Meaning |

|---|---|---|---|

| A5 | FEM M5 | ISO A5 | Medium-heavy |

| A6 | FEM M6 | ISO A6 | Heavy-duty threshold |

| A7 | FEM M7 | ISO A7 | High-intensity heavy duty |

| A8 | FEM M8 | ISO A8 | Extreme/continuous operation |

Why Heavy Duty Gantry Cranes Should Be Customized

Because U and Q only exist within specific operating conditions, not in standard product catalogs.

- Port container handling: High U + High Q

- Chemical equipment manufacturing: Medium U + High Q

- Bridge construction: Medium-to-high U + High Q

This is why heavy duty gantry cranes must be application-driven designs, rather than parameter stacking.

Advantages of Customized Heavy Duty Gantry Cranes

Customized heavy duty gantry cranes emphasize non-standard structural design, optimized for specific conditions such as extreme temperatures or special loads.

Examples include multi-lifting-point synchronous control and automatic load balancing, enabling higher efficiency and energy savings.

Key advantages include:

- Non-standard structures tailored to specific applications

- Operating-condition-driven design

- Longer service life

- Lower maintenance and downtime costs

- High compatibility with site conditions (e.g., low-temperature materials, port wind protection systems)

Applications and Real Project Cases

Heavy duty gantry cranes are widely used in heavy industries, including:

- Port container handling

- Steel plants and precast concrete yards

- Railway freight yards

- Shipyards

- Wind power manufacturing

- Bridge construction

- Chemical equipment manufacturing

Representative projects include:

42-ton Automated Container Gantry Crane, Russia

Supplied by KUANGSHANCRANE for a key Russian project, designed for extreme cold environments down to –40°C, equipped with VFD drives, energy regeneration, ACCS automation, and GPS positioning. The project received high praise during an inspection by President Vladimir Putin.

Port of Poti Container Gantry Crane, Georgia

High-efficiency gantry cranes supplied for container storage, refrigerated yards, and rail transfer, with an annual handling capacity of 80,000 TEU, significantly improving yard efficiency.

750-ton Double Girder Gantry Crane, Zhejiang, China

Featuring dual trolleys, multi-point synchronous lifting, PLC + VFD control, and 10 kV power supply, it achieves 25–30% energy savings.

400-ton Double Girder Gantry Crane, Shandong, China

Designed for high-end chemical equipment manufacturing, integrating anti-sway control, safety monitoring, and intelligent braking logic as part of a large-scale customized crane solution.

Pricing Factors and Reference Cost Range

Pricing is influenced by:

- Capacity and span

- Duty class (A7–A8 typically adds ~20%)

- Level of electrification and automation

- Special requirements (explosion-proof, corrosion resistance, salt spray protection)

- Transportation, installation, and customs costs

In heavy duty gantry crane projects, duty class (A6–A8) often has a greater cost impact than rated capacity itself.

For the same capacity, upgrading from A6 to A7 or A8 typically increases total cost by 15–30%, mainly due to structural fatigue life design, redundancy, and higher-grade electrical systems.

Do You Need a Heavy Duty Gantry Crane?

Think in Terms of Risk, Not Capacity

Question 1: Will the crane operate at high frequency for long periods?

- Multi-shift daily operation?

- Project duration ≥ 10 years?

- Downtime directly affects production or delivery?

Yes: Risk of standard cranes increases significantly

Question 2: Will the crane frequently operate near rated capacity?

- Regular handling of heavy or integral loads?

- Near-full-load operation as a norm?

- Steel structures, chemical equipment, containers, metallurgical materials?

Yes: Heavy-duty design is required

Question 3: Is downtime unacceptable?

- Port, metallurgical, bridge, energy, or EPC projects?

- Downtime cost exceeds equipment price difference?

- Safety audits or third-party inspections required?

Yes: Heavy duty is a risk-control choice

Decision Conclusion (For Procurement Teams)

When high-frequency operation + near-rated loading + high downtime cost coexist, a heavy duty gantry crane should be selected even if the rated capacity is not large.

This is not a performance upgrade, but a risk management decision.

Get Your Heavy Duty Gantry Crane Solution

Every heavy lifting project is a comprehensive test of structure, safety, and engineering experience.

We provide:

- Technical solution design

- Configuration recommendations

- Project-based quotations

- Full life-cycle service support

Contact us today to receive a customized Heavy Duty Gantry Crane solution tailored to your operating conditions.

Do you like what we do?Share it

.png?w=200&h=134)