- EQUIPMENT

-

special cranes

-

Garbage Grab Crane

-

Foundry Overhead Crane

-

Explosion-proof Overhead Crane

-

Tongs Overhead Crane

-

Overhead Crane with Carrier-beam

-

Electromagnetic Overhead Cranes

-

Diesel Hydraulic Straddle Carrier: Flexible Operation and Affordable Solution for Container Handling

-

Upper Spillway Gate Gantry Crane: Reliable Solution for Dam Gate Hoisting and Hydropower Station Operations

-

Harbour Portal Crane: Powerful and Intelligent Solutions for Efficient Port Handling

-

Coke Pot Crane for CDQ: Exceptional Heavy-Duty Red-Hot Coke Handling

-

Emergency Rescue Specialized Crane for Water-Rescue Simulation: Engineered for Lifesaving Training

-

Intelligent Grab Bucket Overhead Crane: Powerful, Precise and Unmanned Bulk Material Handling Solution

-

Custom Multi-Point Suspension Overhead Crane for Large-Span and Load-Sensitive Industrial Buildings

-

Electrolytic Copper Cranes: Specialized in Efficient Cathode Plate Tank Loading and Transfer

-

Nuclear Polar Cranes: Multi-Function Lifting Machinery For Nuclear Power Plants

-

-

Industry Crane

-

Industry Crane

-

Tundish Cranes

-

Slab Cranes

-

Scrap Cranes

-

Billet Cranes

-

Coil,Bar and Plate Handling Cranes

-

Cement And Precast Crane

-

Power Station Crane

-

Ladle Cranes

-

Paper Industry Cranes

-

Waste to Energy Cranes and Biomass Cranes

-

Tailored Overhead Cranes for Aerospace: High Precision, Efficience, Safety and Reliability

-

Anode Baking Multifunctional Cranes: Versatile, High-Temp Resistant & Smart-Controlled Must-Have for Electrolytic Aluminum Industry

-

Multifunctional Crane For Electrolytic Aluminum: Fulfills All Aluminum Electrolysis Processes, Boosts Plant Efficiency

-

Warehouse Stacker Crane for AS/RS: High-Efficiency, Reliable, Fully Automated Storage

-

Slab Handling Overhead Crane: Metallurgical-Grade Crane for Continuous Casting and Slab Yards

-

Anode Carbon Block Stacking Cranes: 6-Layer Stacking, A Lifting Solution for Carbon Plants’ Efficient Transfer

-

Quenching Crane for Heat Treatment: Process-Oriented Overhead Crane Solution

-

Safe & Stable Scrap Charging Overhead Crane for Metallurgical Feeding Operations

-

Forging Overhead Crane: Reliable Lifting Equipment for Heavy-Duty Forging Workshops

-

Mold Handling Crane for AAC Production Line: Reliable Engineered Fixed-Position Lifting Solution

-

Pickling Overhead Cranes: For Acid Mist Environments in Non-ferrous Metal Smelting

-

-

Hoist & Winch Trolley

-

Casting Electric Wire Rope Hoist

-

European Model Electric Hoist

-

Explosion-proof Electric Hoist

-

Low-headroom Electric Hoist

-

Electric Chain Hoist

-

2 Types Explosion-Proof Electric Chain Hoists for Hazardous Zones: Gas & Dust Protection

-

2 Types Explosion-Proof Electric Wire Rope Hoists for Industrial Safety: Reliable Gas & Dust-Proof Solutions

-

Manual Hoists for Precision Lifting: Explore 3 Proven Types for Power-Free Operation

-

Air Pneumatic Hoists: 4 Specialized Designs for Precision, Safety, and Harsh Environments

-

HC Type Electric Hoist: Heavy-duty Wire Rope Hoist for Factory Heavy Lifting

-

-

CRANE Spreader

-

Crane Electromagnetic Lifting Magnets

-

Lifting Electromagnet for Turning and Side Hung

-

Lifting Electromagnet for Thick Plate

-

Specialized Electromagnet for Lifting Steel Plates

-

Lifting Electromagnets for Lifting Steel Plates

-

Lifting Electromagnet for Heavy Rail and Profiled Steel

-

Lifting Electromagnet for High Speed Wier(Coiled Bar)

-

Lifting Electromagnet for Rebar and Steel Pipe

-

Lifting Electromagnet for Bundled Rebar and Profiled Steel

-

Lifting Electromagnet for Billet, Girder Billet and Slab

-

Lifting Electromagnet for Steel Scraps

-

- Crane Spreader

- Crane Hook

- Crane Lifting Tongs and Clamps

-

Crane Electromagnetic Lifting Magnets

- CRANE PARTS

- Transfer Cart

EOT Crane Manufacturers In Russia:Analysis of Key Suppliers Amid Growing Demand

Table of Contents

Currently, the Russian EOT crane market is in a steady growth phase, mainly due to the strong development of the manufacturing industry and the localized industrial development policy promoted by the Russian government in 2024, Russia’s economic performance exceeded the expectations of the manufacturing industry as the main driver of economic growth.EOT cranes, as the core equipment for material handling, assembly line and transportation operations, occupy an important market share. According to statistics, in the first eight months of 2024, Russia’s machinery manufacturing industry increased by nearly 20%, and this growth directly drove the demand for EOT cranes, especially in the mechanical engineering, automotive, electronics and pharmaceutical industries. This guide introduces the top 10 EOT crane manufacturers in Russia to help you understand trusted suppliers and make informed decisions for your business, ranked in no particular order, all information is from the brand’s official website.

EOT Crane Manufacturers in Russia

Iteko Kran

Company information: Iteco Cranes is Russia’s largest manufacturer of full production cycle lifting equipment, headquartered in the innovative industrial cluster of the city of Obninsk. The company covers an area of 4 hectares, including 10,000 square meters of modern production facilities. As an industry leader, the production line is capable of manufacturing overhead cranes with a lifting capacity of up to 250 tons. The company’s production facilities adopt a full-process layout, covering raw material preparation area, box girder assembly area, welding section, crane assembly area, machining area, machine testing area, surface painting area, finished product packaging area and automated warehousing area, as well as a full-time quality testing center. With more than 12 years of professional experience, Iteco Cranes has developed into one of the most trusted brands in the crane manufacturing field in Russia, and has always taken “quality and precision” and “delivery time” as its core business principles. According to statistics, the company has so far designed, manufactured and successfully delivered more than 1,000 units of various types of customized crane equipment, products are widely used in energy, machinery manufacturing, logistics and other industrial sectors.

Established: Founded in 2013

Brand Advantage:

- Strong production capacity: with the factory’s large production base and advanced technology, it is able to manufacture cranes with lifting capacity up to 250 tons.

- Stable product quality: Modern automated digital equipment and three-stage quality control ensure stable product quality. Quality control is performed by HAKC certified experts.

- Respect for customer needs: with its own design and engineering department, it has extensive experience in designing and manufacturing complex lifting mechanisms. Able to build truly personalized equipment, following all parameters and technical specifications.

- Demonstration of the equipment: production is equipped with specialized equipment for controlled assembly, factory testing and demonstration of the equipment. All mechanical devices are checked for compliance with the technical specifications and for proper functioning, and are tested and accepted on the spot by the customer.

- Qualified Installation Team: Has an installation team composed of professionally qualified personnel. Able to carry out crane installation and installation guidance in various complex and narrow environments (e.g. mine shafts, railroad tracks, mines, etc.).

- Openness of the company: customers are always welcome to visit the factory for production audit. Always happy to communicate to determine project details.

Main products: EOT cranes, gantry cranes, crane parts, metal structures, etc.

Applicable industries: Energy, machinery, logistics, etc.

Scope of services: Design, production, installation, commissioning, inspection, maintenance, spare parts supply, dismantling and other comprehensive services.

Customer base: Fixed customers include metal processing companies, machine building and shipbuilding enterprises, design and construction bureaus, leaders in the energy industry and industrial enterprises of the second and third hazardous categories.

Uralkran

Company information: Uralcran is dedicated to providing its customers with efficient and reliable solutions for the entire lifecycle of lifting and transport equipment, from design to modernization and disposal. By combining the experience of Soviet engineers with modern technological innovations, the company continues to improve its technical capabilities and expand its production. As the market leader in lifting and transportation equipment in the Russian Federation, Uralcrane has the largest in-house design and development department in the industry, as well as a strong production base. Since its establishment in 1949, the company has grown steadily to become the largest lifting and transportation equipment manufacturing group in Russia. Today, Uralcrane has grown into a modern, technologically advanced and operationally stable high-tech company, focusing on cutting-edge global technology and providing high-performance, highly reliable specialized equipment to customers in the Russian Federation and internationally.

Established: 1949, with 70+ years of experience

Certification: Product quality in accordance with ISO 9001:2011 (former 9001:2008) quality management system standards

Main products: EOT cranes, gantry cranes, harbor cranes, stacker cranes, etc.

Applicable industries: Metallurgy, construction, machinery, paper, energy, mining, ports, warehouses, shipbuilding, aerospace, chemistry, etc.

Scope of services: Full life cycle services such as equipment selection consulting, design, manufacturing, distribution, installation, commissioning, maintenance, spare parts supply, emergency repair, major maintenance, dismantling and disposal.

Uryupinsky Crane Plant JSC

Company information: JSC ULYUPINSK Crane Works is an enterprise with a history of more than 100 years and a factory area of 42,435 square meters. The main production area includes the main production hall, tooling hall, foundry, heat treatment hall, repair and mechanical hall, warehouse, as well as its own railroad line. Over the past 20 years, the company has successfully produced and put into operation more than 3,500 cranes and 7,500 hoists. As a company specializing in the manufacture of industrial lifting equipment, the company also undertakes installation, maintenance and modernization services. With its long history and accumulated technical experience, the company excels in the development of complex and non-standard lifting and transportation machinery. The company’s in-house design team, mature production team and experienced installation team ensure that all production stages work together efficiently to significantly reduce lead times and equipment costs, helping customers to purchase high quality, certified equipment at the best possible cost to meet the needs of modern businesses. The company offers a full range of lifting and transportation services covering both own-brand and other manufacturers’ equipment, regardless of the location of the company.

Certification: Production in accordance with GOST standards, all products of the factory are certified.

Brand advantages:

- Highly recognized: Lifting equipment produced by the plant operates in more than 250 cities in Russia and abroad. The plant is well known in the former Soviet republics and abroad.

- Affordable prices: The company is an independent manufacturer of lifting equipment covering cranes, electric hoists and accessories. Therefore, the prices do not include any brokerage fees, surcharges and other hidden commissions.

- Reliability. We offer a warranty on all of our ex-factory products. We only work with trustworthy suppliers. Incoming and outgoing goods are strictly controlled.

- The factory is equipped with a specialized team of talents to ensure that the core technology is independent and controllable.

Main products: EOT cranes, gantry cranes, electric hoists, grabs, clamps, spare parts, etc.

Applicable industries: Warehousing, mining, metallurgy, machinery, etc.

Services Scope: Crane design, production, transportation, installation, after-sales service, maintenance, debugging, parts replacement, etc.

Business Crane

Company Information: Business Crane is a specialized supplier of high-quality crane equipment and system integration solutions, with excellent product stability and perfect customer service system, has established a good reputation in the industry. The company is committed to intelligent, automated solutions to help customers improve operational efficiency, the business scope covers the lifting equipment design, delivery, installation and maintenance of the whole process, the company team consists of Russia and the CIS region has a wealth of experience in the technical experts, to provide through the pre-sales consulting, sales implementation and after-sales maintenance of the whole cycle of services, always adhere to the “professional and responsible, timely response” service concept. In order to ensure product quality, Business Crane maintains strategic cooperation with a number of internationally renowned component manufacturers, and purchases core components from global leading brands, including Italy CARIBONI, China NANTE, Germany STAHL CRANE Systems GmbH, Bulgaria SKLADOVA TECHNIKA & ELMOT, and EUROLIFT and Taiwan TECHNIKA & ELMOT. EUROLIFT and TELEKRANE from Taiwan, etc.

Established: Founded in 2018

Certifications: In compliance with the international quality standard ISO9001:2015

Brand Advantage:

- Partner of leading international component manufacturers

- Design sketches and preliminary technical parameters can be completed within 1 working day at the earliest for quotation calculation

- Manufacturing and installation of cranes is carried out by a team of professionals

- 12-month warranty if you choose installation service

Main products: EOT cranes, gantry cranes, fixed-pillar jib cranes, electric hoists, chain hoists, motors, etc.

Scope of services: Development, design, implementation, installation, maintenance and dismantling of lifting systems

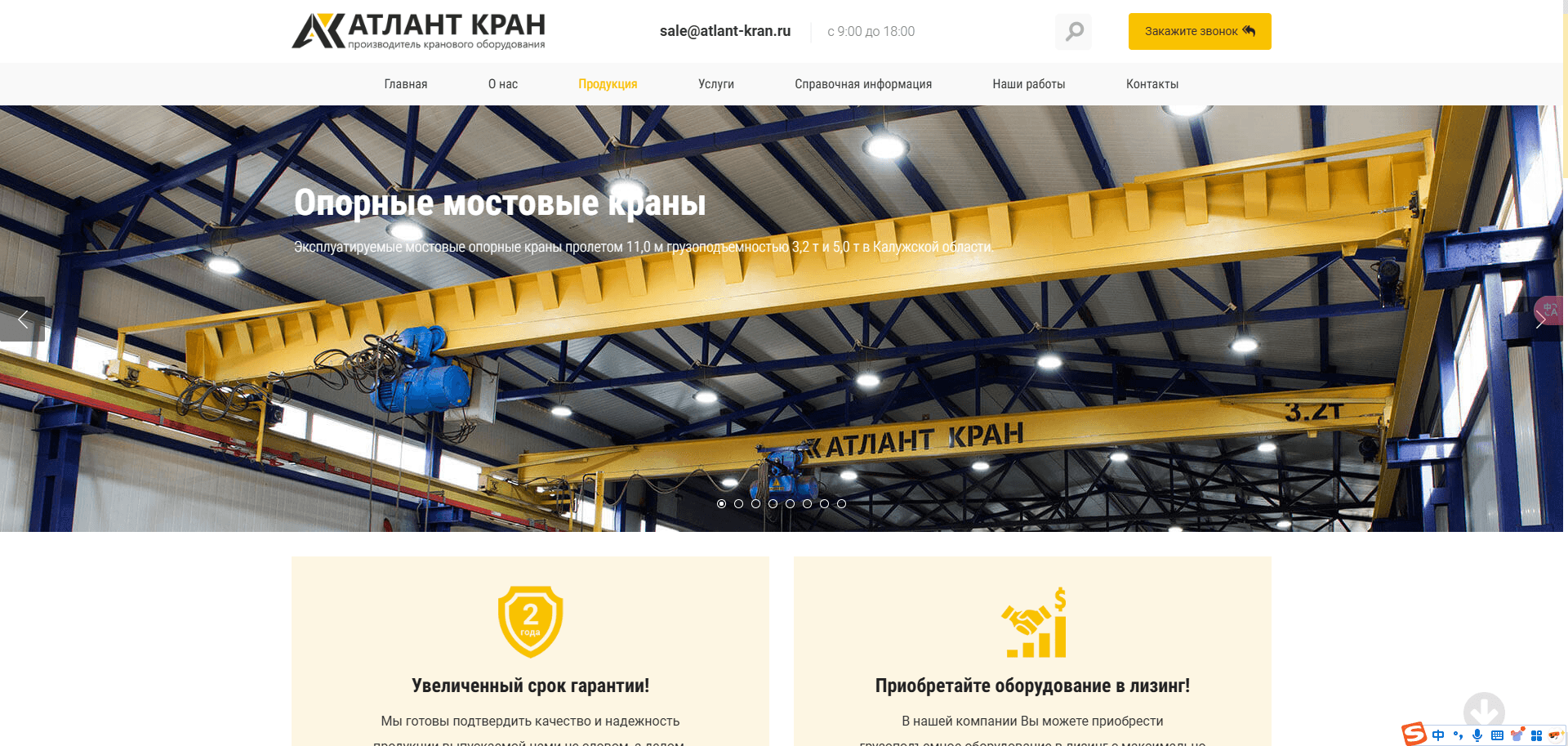

Atlant Kran Company

Company Information: Atlant Kran Company is one of the leading companies in the lifting equipment industry with more than 10 years of experience in the market. The company established its first production line of industrial cranes in the Moscow Region in 2008, and then, due to business expansion, added a second production line in the Rostov Region in 2015, with a total production area of 1,900 square meters. The company is well equipped with its own production facilities, including lathes, milling machines, grinders, band saws, drilling machines, etc., ensuring in-house manufacturing capabilities.In 2020, in order to optimize logistics and expand production capacity, Atlant Kran Company relocated its production base and warehouses to a new location in the Moscow region, where it also opened a sales office.Atlant Kran Company adheres to the principle of customized service, providing individualized lifting cranes to meet the needs of different companies. Atlant Kran Company is committed to customized service and provides individual lifting equipment solutions for the needs of different companies. The company’s experience in the industry has helped many of its customers to increase their productivity. Atlant Kran Company’s products are successfully used by industrial enterprises in Moscow, St. Petersburg, Rostov-on-Don, Krasnodar, Ekaterinburg, Surgut and other major Russian cities.

Established: Unspecified time of establishment, 10+ years of industry experience

Brand Advantage:

- Imported components: using high-quality imported components to ensure economic and durable products.

- Own production: own factory, fast delivery, no intermediate links.

- Professional team: licensed technicians, to protect the quality of installation and service.

- Certification guarantee: production and products are certified.

- Customized Solutions: Provide personalized design according to customer needs.

- Round-the-clock support: Provide continuous technical consultation and after-sales service guarantee during working days, non-working hours and after the warranty period.

Main products: EOT cranes, gantry cranes, manual overhead cranes, etc.

Scope of services: Design, production, installation, service, testing, dismantling, etc.

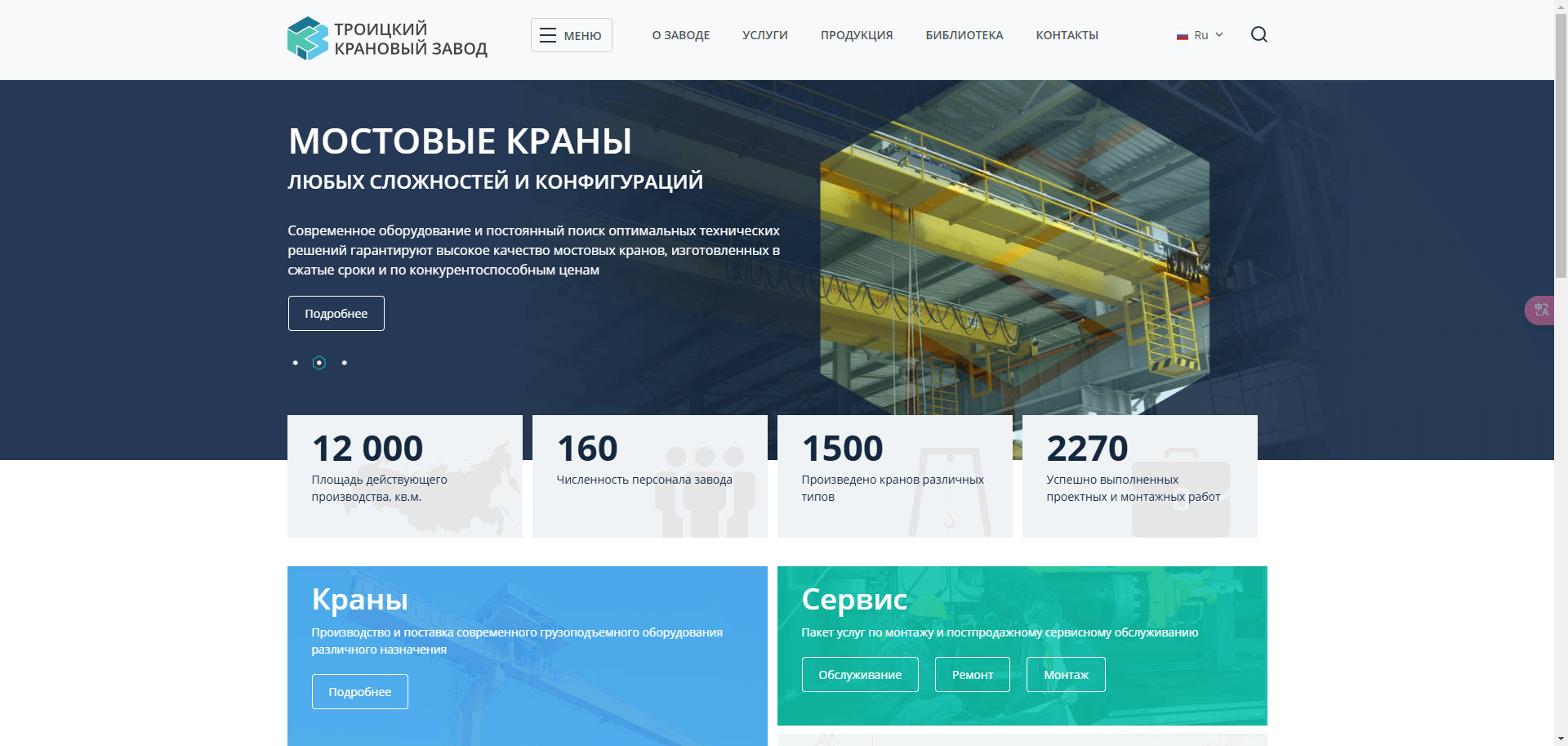

TKZ crane

Company Information: Troitsk Crane Works (TKZ) is a leading Russian manufacturer of lifting equipment, founded in 2005, initially as a Russian-Dutch joint venture (Lemmens Troitsk Crane Works). 2012 after the withdrawal of the Dutch capital, the enterprise was completely localized and renamed. Headquartered in Troitsk, Moscow, the company has a modern 12,000 square meters production base, focusing on the provision of high-performance special lifting equipment for ships, nuclear power, metallurgy and other heavy industry. The factory has more than 50 production complexes and machines and various lifting equipment. Through the localization of its technology (derived from Lemmens Transportation Technology in the Netherlands) and the technical cooperation with Sormec SRL in Italy, TKZ has realized its own innovation of core technology. Since its establishment 13 years ago, its products have covered more than 50 regions in Russia and neighboring countries, and the company is in the process of deepening the localization of its products through the construction of a new 3-hectare plant.

Established: Since 2005, the company has been operating independently for 13 years

Certifications: All products supplied hold the necessary certificates.

Brand Advantage:

- Top technology: localized European technology + Italian cooperation, international leading parameters.

- Rigorous quality control: own test bench, quality is guaranteed.

- In-depth service: long-term reciprocal cooperation, full-cycle professional support.

Main products: EOT cranes, jib cranes, gantry cranes, ship cranes, etc.

Applicable industries: Shipbuilding, nuclear energy, metallurgy, etc.

Scope of services: Design, production, testing, supply, installation, maintenance, repair

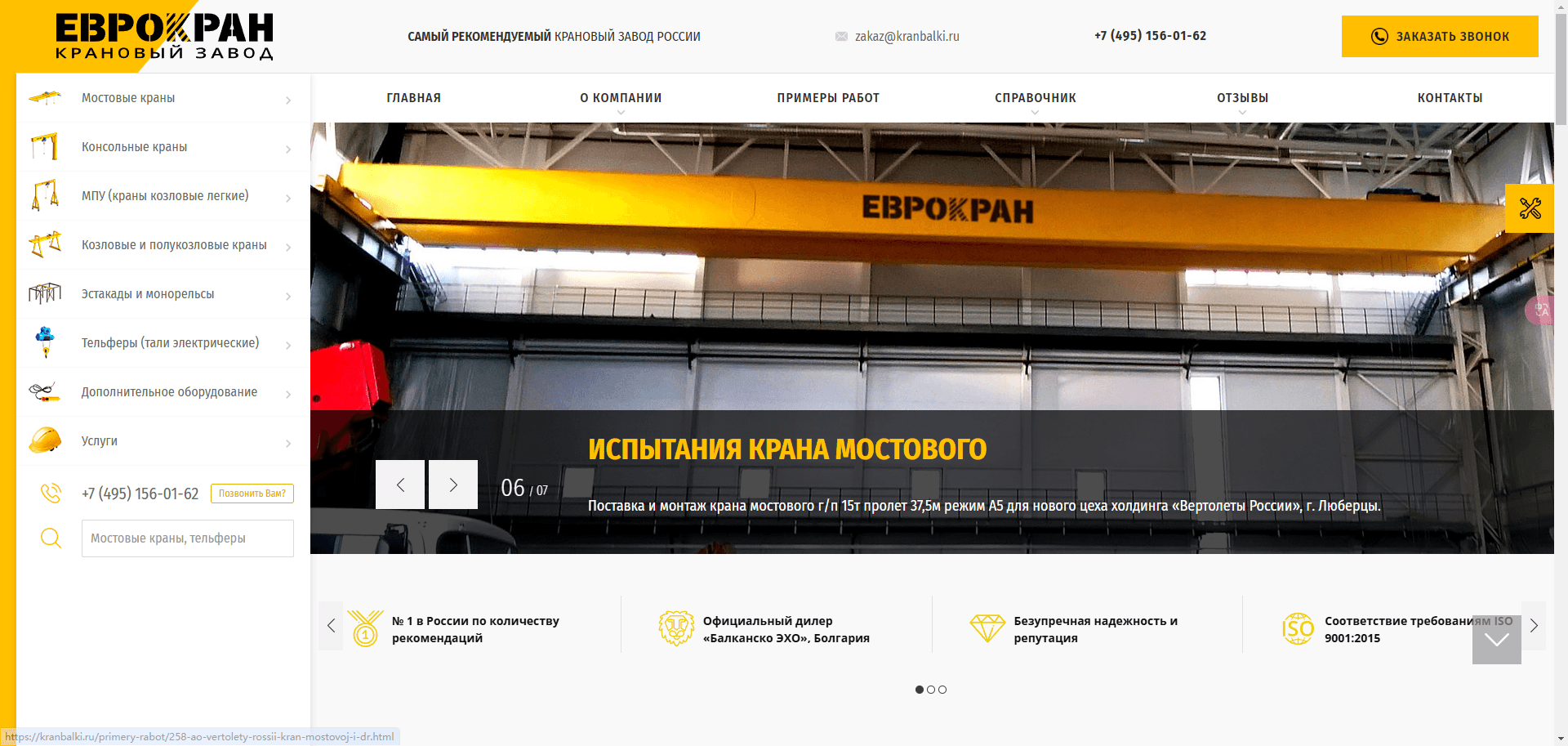

Kranbalki

Company information: “EUROCRANE” is one of the leading companies in the field of lifting equipment manufacturing in Russia, since its establishment in 2009, has always been focused on the research and development of industrial lifting equipment, production and technical services. Headquartered in Lyubeltsy, Moscow region, the company has a modern production base, with a full range of services from non-standard design, manufacturing to installation and maintenance capabilities. So far, it has served more than 1,300 large, medium and small enterprises, and its professional strength has been widely recognized in the market, and at the same time, it has also been rated by Analytic Research Group as “the most recommended crane manufacturer in Russia”, and more than 30% of the customers have cooperated with us through referrals, which confirms the quality of its services and the trust of its customers. The company’s core strengths are reflected in the technical reliability, efficient customization capabilities and long-term value commitment, and cooperation with the world’s top component suppliers to ensure the safety and durability of the equipment; with more than 10 years of industry cultivation, EUROCRANE not only provides standardized equipment, but also committed to become a strategic partner for customers to optimize production processes and improve efficiency.

Established: Founded in 2009

Certification: in line with international quality standards ISO9001:2015

Brand Advantage:

- Good reputation: highly recommended in the industry, Russia’s first recommended lifting equipment suppliers, more than 30% of customers for referrals

- Long warranty: crane warranty up to 5 years

- With independent production base and technical team, can quickly respond to individual needs

Main products: EOT cranes, gantry cranes, jib cranes, electric hoists, metal structures, etc.

Applicable industries: machinery, automotive maintenance (СТО), metallurgy, shipbuilding, power and energy, construction, warehousing, etc.

Scope of services: crane design, production, installation, dismantling, inspection, Maintenance, remodeling

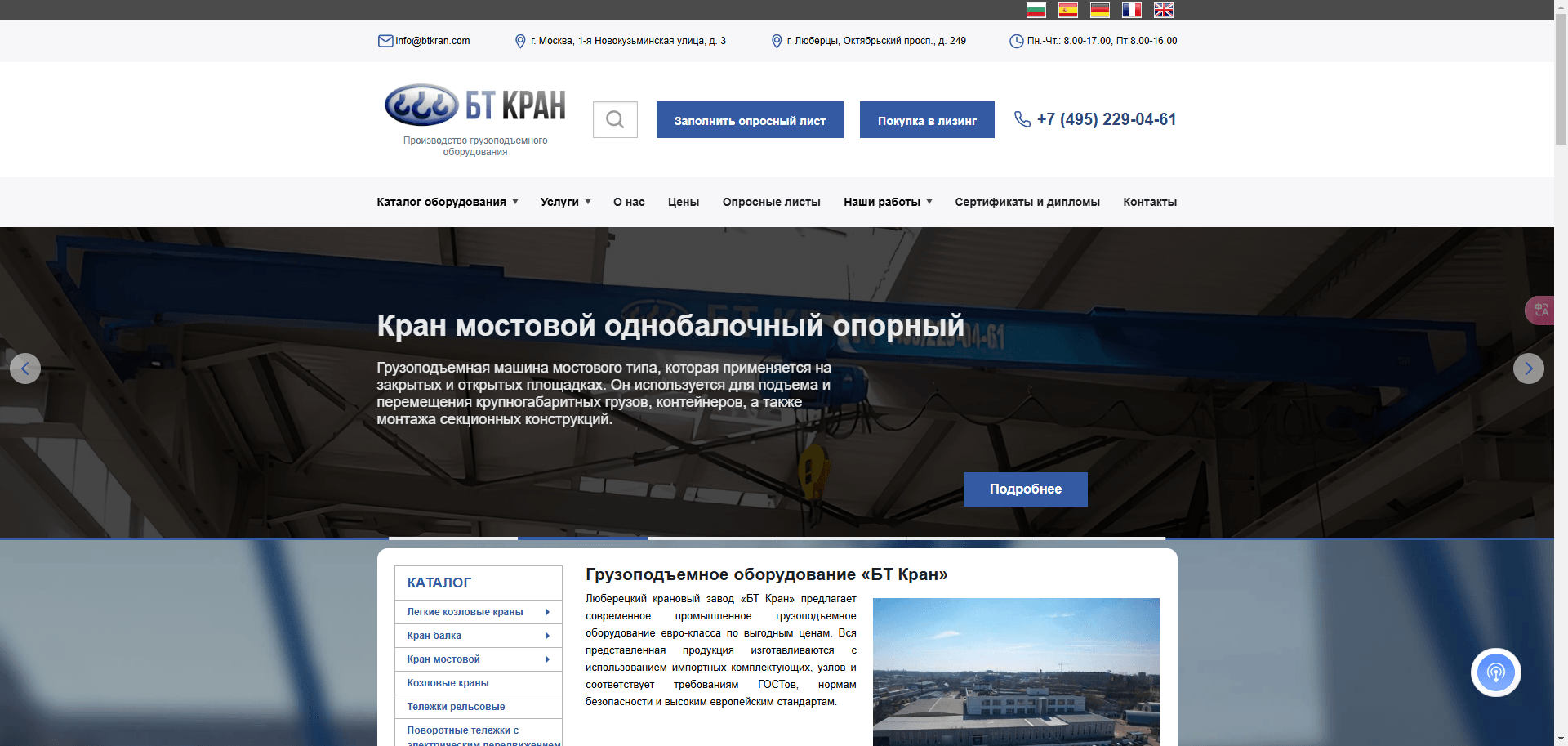

BT Crane

Company information: BTKran is a Russian professional crane manufacturer specializing in the development, production and installation services of bridge cranes (EOT), gantry cranes, jib cranes and special lifting equipment. The company is known for its high load capacity, reliability and customized solutions for a wide range of industrial, energy, metallurgical and logistic applications.BTKran has its own production plant, offering products at competitive prices, with modern European industrial design and imported components to ensure safe and efficient workflow, while optimizing productivity and improving the quality of operations. The company has state-of-the-art production facilities and works with long-term suppliers in Bulgaria to provide a diverse range of solutions, including local Russian components. As one of the market leaders, BTKran’s lifting equipment is widely recognized in Russia, the CIS countries and beyond, and is used by small, medium and large enterprises in a wide range of industries. The company adheres to strict industry regulatory standards and all products are rigorously tested to ensure their reliability and safety. Dedicated to producing reliable lifting equipment characterized by efficiency, reliability, safety and ergonomics.

Certifications: compliance with national standards (GOST), safety standards and high European standards

Brand Advantage:

- Quality assurance, key components (motor, reducer, control system) are selected from international famous brands (e.g. Siemens, ABB).

- Own production base: modernized manufacturing facilities, equipped with CNC machining, automated welding and strict quality inspection process.

- After-sales support: provide technical consultation, spare parts supply and equipment life cycle maintenance.

Main products: EOT crane, gantry cranes, jib cranes, special cranes, etc.

Applicable industries: metallurgical plants, power stations, machinery manufacturing enterprises, etc.

Scope of services: Manufacturing, installation, commissioning, maintenance and modernization services.

ZAO SMM

Company information: ZAO SMM is a specialized industrial equipment manufacturing company based in Russia, specializing in the production and supply of lifting equipment and related industrial solutions. With over 60,000 square meters of production area, the company is always committed to providing high-quality lifting equipment.SMM’s specialists have many years of experience in the design, production and maintenance of lifting equipment, and are able to handle work on all types of equipment. The company personalizes each crane project in strict accordance with the customer’s technical tasks. The company designs EOT cranes with a load capacity of up to 500 tons, which are widely used for loading and unloading operations in industrial workshops, open and closed warehouses, as well as in installation areas. The current workforce of more than 600 employees contains specialized teams with complete R&D, manufacturing and testing capabilities.

Certifications: In accordance with the quality management system ISO 9001:2015

Brand Advantage:

- Offer a complete lifecycle: including lifting system design, manufacturing, installation, service and maintenance.

- Multiple service centers: fast response to customer needs, timely technical support

Main products: Port cranes, EOT cranes, gantry cranes, ship cranes, etc.

Applicable industries: ports, shipbuilding, transportation, mining, metallurgy, nuclear industry, etc.

Scope of services: Design, manufacturing, installation, transportation, service, maintenance, spare parts supply

Girffe crane

Company information: GIRAFFE is the largest manufacturer of tower cranes in Russia and a specialized manufacturer of EOT. GIRAFFE has its own warehousing system, keeping many types of products in stock to shorten the delivery cycle. Since 2023, GIRAFFE has fully adopted the Russian self-produced parts to replace imported ones, and provides flexible cooperation programs including purchase and lease while ensuring the reliability and maintenance convenience of the equipment, and maintains a good circulation of the equipment in the second-hand market, with the service life of the whole machine up to 16 years, which is at the leading level in the industry. The service life of the whole machine is up to 16 years, which is the leading level in the industry. The company has a professional service team to provide a full cycle of technical support services from program design to installation and commissioning and later operation and maintenance. The company occupies more than 20% of the market share, the production of more than 10,000 cranes, GIRAFFE to provide customers with perfect construction machinery and first-class service, so that the brand in the Russian crane manufacturing market occupies a leading position.

Established: No specific date of foundation was specified, the crane construction phase started in 1949

Certifications: in compliance with ГОСТ Р ИСО 9001-2015 (equivalent to the international standard ISO 9001:2015)

Brand Advantages:

- All-climate design: suitable for both cold and hot environments (-40°C to 40°C).

- Significant cost-effectiveness: long crane service life and reduced maintenance costs.

Main products: Tower cranes, EOT cranes, gantry cranes, etc.

Applicable industries: industry, construction, warehousing, etc.

Scope of services: consulting, guidance, design, installation, commissioning, maintenance, repair, dismantling, operation training

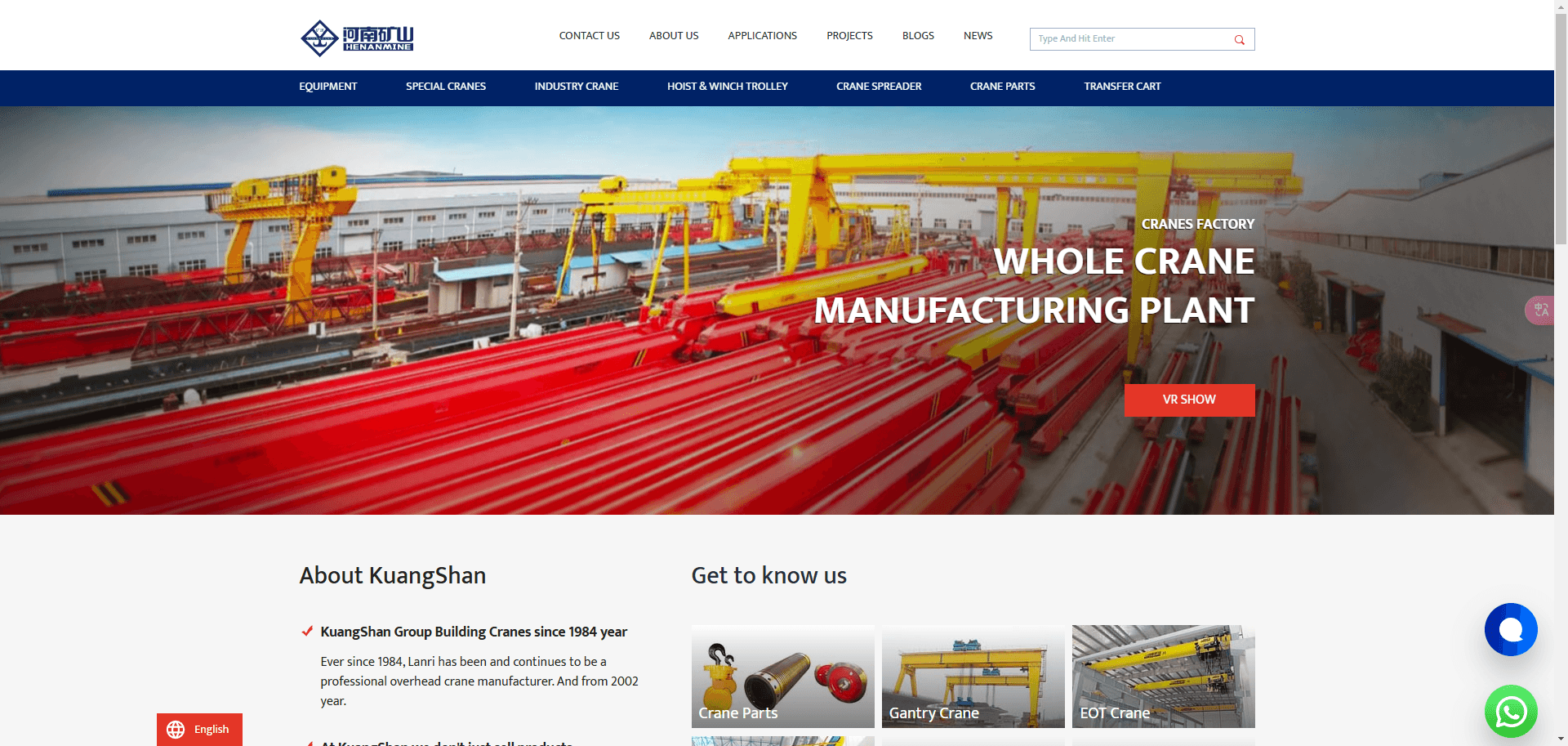

In addition to local Russian brands, there are also many international EOT crane manufacturers, such as Chinese manufacturers Weihua and Henan Mining, etc. With advanced technology, mature supply chain and competitive price, these enterprises It has become an attractive and not-to-be-missed option. This has provided the Russian market with richer options and prompted buyers to make more comprehensive considerations when making decisions.

Against this background, Henan Mining is committed to combining the high quality of Chinese manufacturing with localized services in Russia. Relying on China’s strong R&D strength and large-scale production advantages, it provides more cost-effective and adaptable solutions for the special needs of Russian customers.

China Heading EOT Crane Manufacturer: Henan Kuangshan

Company information

Henan Kuangshan Crane Co., Ltd. was founded in 2002, headquartered in China’s “hometown of lifting machinery”—— Changyuan City, Henan Province. The company covers an area of 1,620,000 square meters, with more than 5,100 employees, is one of the leading crane manufacturers in China, integrating R & D, design, manufacturing, sales and service, and is committed to providing cost-effective lifting and material handling solutions for customers around the world.

Brand Advantages

- Industry position: production and sales volume and market share for many years in the industry, is one of the largest crane manufacturers in China.

- Intelligent manufacturing: 310 sets of handling and welding robots have been installed, with the equipment networking rate reaching 95%; 32 welding lines are in operation, with the product automation rate reaching 85%.

- Technical strength: has a national enterprise technology center, accumulated more than 700 national patents and provincial scientific and technological achievements, leading participation in the development of China’s crane industry standards.

- Global service: business covers 122 countries, participating in a number of international key projects, such as Pakistan Lahore rail transit, Vietnam Yishan steel project.

Products and Services

- Main products: more than 110 kinds of products such as bridge cranes, gantry cranes, electric hoists, jib cranes, European cranes, intelligent cranes and so on.

- Applicable industries: Widely used in aerospace, automotive, chemical, railroad, steel, machinery manufacturing, ports, construction and waste incineration treatment and other fields.

- Full-cycle service: Provide full life cycle service from R&D and design to manufacturing, installation and maintenance to ensure customers get efficient and reliable solutions.

Certifications and Honors

- Quality management: ISO9001 certified, compliant with GB/T 3811-2008 crane design specification, CE certification and special equipment manufacturing license.

- Industry Recognition: Won the “China Industry Award Nomination”, “National Green Factory”, “National Manufacturing Single Champion Enterprise” and other 500 honors. More than 500 honors.

Innovation and Future

The company insists on innovation-driven development, and carries out cooperation with many famous universities to promote the crane industry to the intelligent, green, high-quality direction. In the future, we will continue to expand the scale of intelligent production, planning to build more than 500 sets of robots and 50 welding lines to further enhance the level of automation.

Henan Kuangshan Exported To Russia Cases

Sixth Cooperation with Russian Customers: EOT Crane Parts

Customer Background

The customer is a well-known heavy crane manufacturer in Russia, which has extremely strict requirements for product quality and pays attention to details and process precision. Since the first cooperation at the beginning of last year, the two sides have established a stable relationship, and the customer has re-purchased many times, showing a high degree of recognition of Henan Mining’s products and services.

Cooperation history

- Initial cooperation (early last year): In 2023, the customer purchased EOT crane parts for the first time and strictly evaluated the product quality and delivery efficiency.

- Continuous repurchase: up to this order, the customer has placed the sixth order, and gradually handed over more EOT crane parts and complete machine orders to Henan Mining for production.

Customer demand and response

- Requirements: Customers have very high requirements for parts precision, durability and delivery time.

- Response: Adopting high-precision machining technology to ensure that the products meet the strict standards, optimizing the production process to ensure on-time delivery, and providing perfect after-sales support to ensure that customers have no worries.

Customized Crane Parts for Aluminum Plant in Russia

Project Background

Client’s Requirement: A crane manufacturer in Russia customized special cranes for an aluminum plant, but due to transportation limitations and localized production requirements, the client only purchased all the ancillary components except for the main girder, including the electrical system, drive unit, control system and so on.

Challenge: The aluminum plant environment requires high temperature resistance, corrosion resistance and control accuracy of the equipment, which needs to be customized to meet the special working conditions.

Project Highlights

- Complete set of supply without main girder ——the customer only purchases a complete set of crane parts (without main girder), and we provide the core electrical, mechanical and control systems, reflecting the depth of trust in our technical capabilities.

- Adaptation to the harsh environment——Integrated high-precision encoder & PLC control system ensures the stable operation of the crane in the high-temperature and dusty environment of the aluminum plant.

- Innovative Transportation Solution——Precision cutting + modular transportation for oversized parts ensures no loss of performance after reorganization and reduces logistics costs for customers.

Customer Cooperation and Acceptance

- Rigorous testing: The customer went to our factory to conduct full load testing & durability verification to confirm that all the parts meet the stringent standards of the aluminum factory.

- Long-term cooperation: Based on the high quality delivery of this project, the customer clearly indicated that they would establish a strategic supply chain partnership with us and expand the scope of procurement in the future.

Conclusion

With the support of Russian government policies, the trend of “import substitution” has become more and more obvious. With the intensification of trade barriers between Russia and traditional industrial countries such as Europe, Japan and South Korea, local manufacturers are expanding rapidly, such as Uralkran, TKZ and other local brands, which are gradually replacing the share of imported brands in terms of their comprehensive strengths in terms of customization capability, delivery lead time and after-sales response. Local brands, such as Uralkran and TKZ, have shown competitiveness in terms of their comprehensive strengths in customization capability, delivery lead time and after-sales response, gradually replacing imported brands. Despite the slowdown in manufacturing activities in Russia in the first half of 2025, competition between local Russian manufacturers and international suppliers will continue to drive the market in the long run. In the future, with the deepening of Russia’s industrial autonomy strategy, it is expected that the market penetration of local brands will continue to increase and compete with international brands in high value-added areas (such as intelligent cranes and special lifting equipment). At the same time, Chinese suppliers such as Henan Mining are becoming the new choice in the Russian market with their advanced technology, high cost performance and flexible supply chain advantages. The lifting solutions provided by Henan Mining not only meet international standards, but also respond quickly to localized needs, providing Russian enterprises with reliable alternatives to local and European and American brands, further enriching the diversity of the market and promoting the efficient development of the industry.

Do you like what we do?Share it

.png?w=200&h=134)