- EQUIPMENT

-

special cranes

-

Garbage Grab Crane

-

Foundry Overhead Crane

-

Explosion-proof Overhead Crane

-

Tongs Overhead Crane

-

Overhead Crane with Carrier-beam

-

Electromagnetic Overhead Cranes

-

Diesel Hydraulic Straddle Carrier: Flexible Operation and Affordable Solution for Container Handling

-

Upper Spillway Gate Gantry Crane: Reliable Solution for Dam Gate Hoisting and Hydropower Station Operations

-

Harbour Portal Crane: Powerful and Intelligent Solutions for Efficient Port Handling

-

Coke Pot Crane for CDQ: Exceptional Heavy-Duty Red-Hot Coke Handling

-

Emergency Rescue Specialized Crane for Water-Rescue Simulation: Engineered for Lifesaving Training

-

Intelligent Grab Bucket Overhead Crane: Powerful, Precise and Unmanned Bulk Material Handling Solution

-

Custom Multi-Point Suspension Overhead Crane for Large-Span and Load-Sensitive Industrial Buildings

-

Electrolytic Copper Cranes: Specialized in Efficient Cathode Plate Tank Loading and Transfer

-

Nuclear Polar Cranes: Multi-Function Lifting Machinery For Nuclear Power Plants

-

-

Industry Crane

-

Industry Crane

-

Tundish Cranes

-

Slab Cranes

-

Scrap Cranes

-

Billet Cranes

-

Coil,Bar and Plate Handling Cranes

-

Cement And Precast Crane

-

Power Station Crane

-

Ladle Cranes

-

Paper Industry Cranes

-

Waste to Energy Cranes and Biomass Cranes

-

Tailored Overhead Cranes for Aerospace: High Precision, Efficience, Safety and Reliability

-

Anode Baking Multifunctional Cranes: Versatile, High-Temp Resistant & Smart-Controlled Must-Have for Electrolytic Aluminum Industry

-

Multifunctional Crane For Electrolytic Aluminum: Fulfills All Aluminum Electrolysis Processes, Boosts Plant Efficiency

-

Warehouse Stacker Crane for AS/RS: High-Efficiency, Reliable, Fully Automated Storage

-

Slab Handling Overhead Crane: Metallurgical-Grade Crane for Continuous Casting and Slab Yards

-

Anode Carbon Block Stacking Cranes: 6-Layer Stacking, A Lifting Solution for Carbon Plants’ Efficient Transfer

-

Quenching Crane for Heat Treatment: Process-Oriented Overhead Crane Solution

-

Safe & Stable Scrap Charging Overhead Crane for Metallurgical Feeding Operations

-

Forging Overhead Crane: Reliable Lifting Equipment for Heavy-Duty Forging Workshops

-

Mold Handling Crane for AAC Production Line: Reliable Engineered Fixed-Position Lifting Solution

-

-

Hoist & Winch Trolley

-

Casting Electric Wire Rope Hoist

-

European Model Electric Hoist

-

Explosion-proof Electric Hoist

-

Low-headroom Electric Hoist

-

Electric Chain Hoist

-

2 Types Explosion-Proof Electric Chain Hoists for Hazardous Zones: Gas & Dust Protection

-

2 Types Explosion-Proof Electric Wire Rope Hoists for Industrial Safety: Reliable Gas & Dust-Proof Solutions

-

Manual Hoists for Precision Lifting: Explore 3 Proven Types for Power-Free Operation

-

Air Pneumatic Hoists: 4 Specialized Designs for Precision, Safety, and Harsh Environments

-

HC Type Electric Hoist: Heavy-duty Wire Rope Hoist for Factory Heavy Lifting

-

-

CRANE Spreader

-

Crane Electromagnetic Lifting Magnets

-

Lifting Electromagnet for Turning and Side Hung

-

Lifting Electromagnet for Thick Plate

-

Specialized Electromagnet for Lifting Steel Plates

-

Lifting Electromagnets for Lifting Steel Plates

-

Lifting Electromagnet for Heavy Rail and Profiled Steel

-

Lifting Electromagnet for High Speed Wier(Coiled Bar)

-

Lifting Electromagnet for Rebar and Steel Pipe

-

Lifting Electromagnet for Bundled Rebar and Profiled Steel

-

Lifting Electromagnet for Billet, Girder Billet and Slab

-

Lifting Electromagnet for Steel Scraps

-

- Crane Spreader

- Crane Hook

- Crane Lifting Tongs and Clamps

-

Crane Electromagnetic Lifting Magnets

- CRANE PARTS

- Transfer Cart

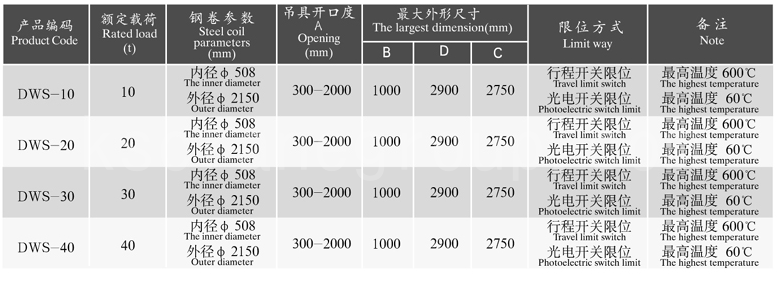

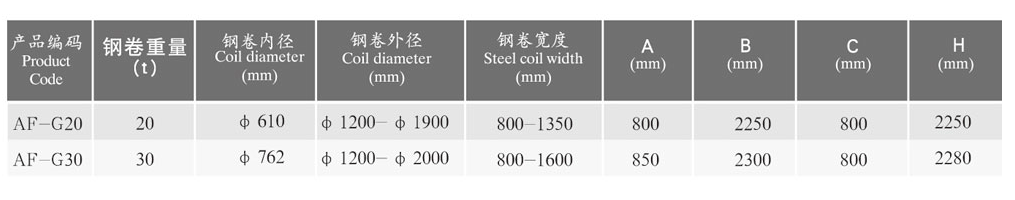

Coil Grabs/Coil Lifting Tongs

Transport and turning of tied metal strip coils or similar shaped loads.

Connection to crane with hangers, crane hook suspensions, attachment points or rope pulleys

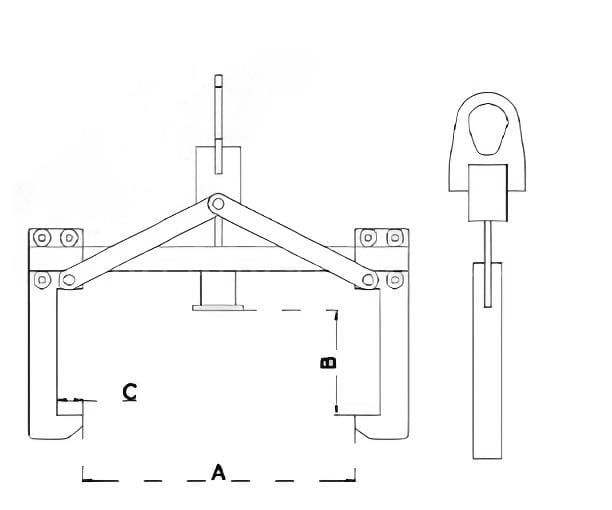

Horizontal Coil Grab

Electromotive Horizontal Coil Grab

Electromotive Horizontal Coil Grab

Flip Clamp

Single Side Vertical Roll Clamp

Double-sided vertical roll clamp

Dual Vertical Reel Clamp

Horizontal Coil Grab

Mechanical Horizontal Coil Clamps can meet the needs of large steel mills, ports, terminals and other units for lifting large quantities of horizontal coiled objects

Material: low carbon alloy steel

Can be customized

Widely used in steel mills, industry, logistics, metallurgy, construction, shipbuilding, bridge engineering, etc.

| Load(T) | A(mm) | B(mm) | C(mm) | Self weight(kg) |

| 25t | 800-1500 | 750 | 200 | 1500 |

| 30t | 1100-2100 | 1000 | 250 | 2000 |

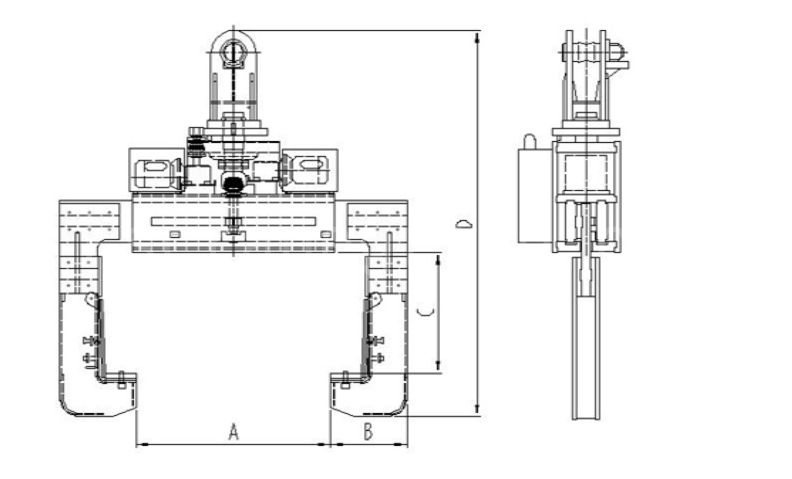

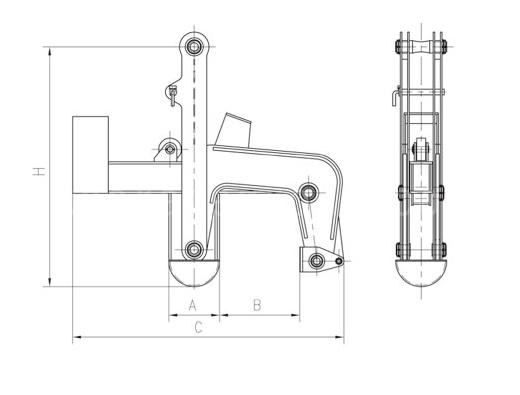

Electromotive Horizontal Coil Grab(Triple Screw Drive)

Electric horizontal coil clamp is a kind of lifting tool specialized in lifting and transporting horizontal steel coils, this clamp is three-screw drive, with compact structure, smooth action, simple operation and other advantages, it is a more advanced lifting tool.

Advantage:

- The main body is made of low carbon steel plate, laser cut, welded and assembled by experienced technicians, and the surface is sprayed with plastic.

- Transformer is embedded design, design optimization, safe and reliable.

- The dimensions are cut by CNC, precise size and high density.

- The finished product is treated with multi-layer anti-rust treatment, fine workmanship, quality assurance.

The shape and installation dimensions are shown below, and can be designed according to the user’s requirements.

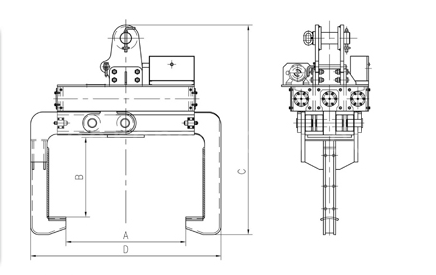

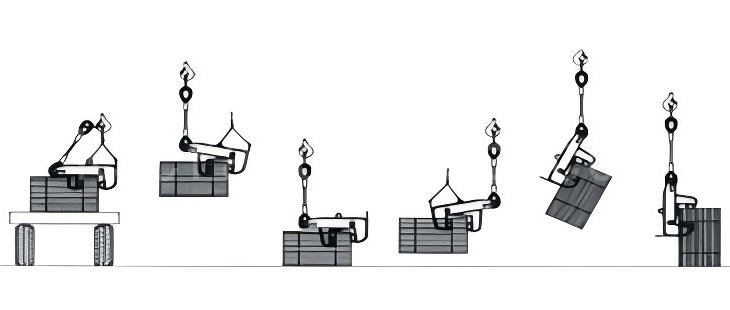

Electric Steel Coil Grippers (Rack and Pinion Drive)

Electric lying coil clamp is a kind of spreader specially used for lifting and transporting lying steel coils, widely used in steel mills, wharves, warehouses and other steel coil storage occasions, this kind of spreader due to the opening and closing of the jaws in the process of the height direction of the size of the unchanged characteristics, especially suitable for when the crane lifting height space is limited, the crane must be equipped with a cable reel.

Features

- The clamp has lifting lugs, clamp legs, clamp leg drive system, electrical and electrical control systems, cable reels and other parts of the components

- After clamping the steel coil, it opens about 20mm automatically to ensure that the operation does not hurt the steel coil.

- The internal and external stroke of the clamp are fixed block positioning, reliable performance and low maintenance rate.

- The clamp can be equipped with height centering function, side plate with polyurethane protection and other functions.

- Clamp contains various sensors, with anti-over-clamping, load-bearing anti-opening misoperation protection.

- PLC control, with a spreader working status warning light.

- Material: low carbon alloy steel

- Widely used in industry, logistics, metallurgy, construction, shipbuilding, bridge engineering, etc.

The outline and installation dimensions are shown below, and can be designed according to user requirements.

| 载荷(t) Loading | A | B | C | D | 自重(kg)weight |

| 15 | 450-1600 | 450 | 800 | 2500 | 2300 |

| 20 | 450-1750 | 500 | 800 | 2600 | 2800 |

| 30 | 450-2100 | 500 | 850 | 2700 | 3000 |

| 40 | 650-2200 | 500 | 900 | 2750 | 4000 |

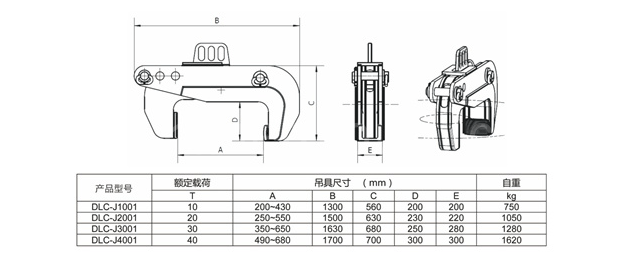

Flip Clamp

Flip clamp through the principle of mechanical scissors, the vertical placement of the coil of steel on one side of the grasp, to complete the loading and unloading of the coil of steel, when changing the starting point of gravity, can be when the coil of steel from vertical to horizontal, but also to make the coil of steel from the horizontal to vertical flip. This kind of clamp is both economical and practical.

Features

- Lifting weight: 15-40T

- Material: low carbon alloy steel

- Widely used in industry, logistics, metallurgy, construction, shipbuilding, bridge engineering, etc.

- It is mainly used for lifting vertical rolls, and the lifting process is safe and reliable without external force (clamping by its own gravity). According to the lifting frequency and lifting requirements to choose the appropriate model.

- When lifting the vertical coil, the two pairs of internal and external clamping legs of the clamp move separately, and the two wall thicknesses in the direction of diameter are clamped respectively during operation.

- When working, the clamp and the steel coil is not now on the sliding, the operation does not hurt the steel coil.

- Low spreader cost

- The space required for operation is small, and the restriction on the spacing of steel coil stacking, or lifting order is not obvious.

- But need the cooperation of the ground personnel, low operating efficiency

- Operation to ensure that the clamp hook hook to the bottom, for different widths of steel coils need to adjust the position

Shape and installation dimensions are shown below, can be designed according to user requirements.

Electric Flip Clamp

Electric flip clamp is a kind of spreader used for coil steel lifting and flipping. It is mainly composed of three parts: electrical part, mechanical part and main body. Insert the outer leg of the clamp into the center hole of the coil plate, start the clamping motor and clamp the coil plate firmly. After lifting the rolled plate, start the overturning motor, drive the clamp legs and rolled plate to rotate through the conduction device, and stop automatically at another working station. The clamp turning operation can be carried out while the crane is running.

Advantages

- Smooth lifting, strong load-bearing capacity, widely used in steel mills, warehouses, equipment handling, oilfields, ports, mechanical and electrical, transportation and other industries lifting and hoisting.

- Made of manganese steel Q355B, high temperature quenching process, smooth surface and high strength.

- Reasonable structural design, rigorous processing technology, rest assured that practical

- Each product should be strictly tested before putting into use, quality assured!

- Width, length, style can be customized according to demand

Single Side Vertical Roll Clamp

Suitable for steel coil handling, with coil turning function, through different clamping methods can change the state of steel coil placement (lying or standing).

Characteristic

- Low spreader cost

- The restriction on the spacing of steel coils stacking, or lifting order is not obvious.

- However, it needs the cooperation of ground personnel, and the operation efficiency is low.

- Material: low carbon alloy steel

- Widely used in steel mills, industry, logistics, metallurgy, construction, shipbuilding, bridge engineering, etc.

The shape and installation dimensions are shown below, and can be designed according to customer requirements.

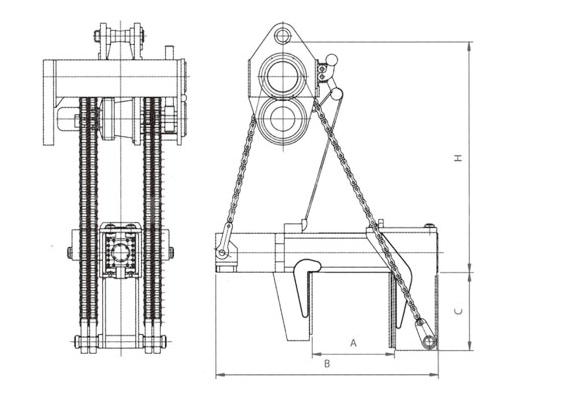

Double-sided Vertical Roll Clamp

Used for lifting cold rolled vertical coil, the fixture adopts automatic opening and closing lever type working principle. Its structure is simple and reasonable, flexible action, safe and reliable transportation. Hanging on the single hook crane, relying on the opening and closing device to open the clamp and clamping steel coil, without external power, mainly used for cold rolled vertical coil loading and unloading hood annealing furnace operation.

Characteristics

- When lifting the vertical coil, the two pairs of internal and external clamp legs move separately, and the two wall thicknesses in the direction of diameter are clamped respectively during operation.

- After lifting the vertical coil, the ground of the vertical coil is absolutely horizontal.

- During operation, there is no relative sliding between the clamp and the steel coil, so the steel coil will not be hurt during operation.

- The clamping force of the jaws of the clamp on the steel coil is twice as small as that of a jaw clamp, the contact stress is small, and the stress damage of the clamp on the steel coil is small.

- Material: low carbon alloy steel

- Widely used in steel mills, industry, logistics, metallurgy, construction, shipbuilding, bridge engineering, etc.

The outline and installation dimensions are shown below, and can be designed according to user requirements.

| Load(T) | Coil parameter(mm) | Tong parameter(mm) | Self weight(kg) | ||||||

| outer | inner | A | B | D | E | F | H | ||

| 25 | 1200-1850 | 508-610 | 3825 | 2000 | 470 | 500 | 450 | 5000 | 5850 |

| 35 | 1350-2150 | 508-610 | 3960 | 2250 | 470 | 500 | 450 | 5200 | 7740 |

| 45 | 1350-2200 | 508-610 | 4250 | 2400 | 470 | 500 | 450 | 5600 | 8630 |

Dual Vertical Reel Clamp

Vertical coil clamp is a lifting tool specially used for lifting the coil plate when it is in vertical position. Applications include ports and harbors, machinery manufacturing, metallurgy, logistics and transportation, electric power construction and other fields. We can customize the double vertical clamp according to customer’s requirements. The material is low carbon alloy steel, which is widely used in steel mills, industry, logistics, metallurgy, construction, ships, bridge engineering and so on.

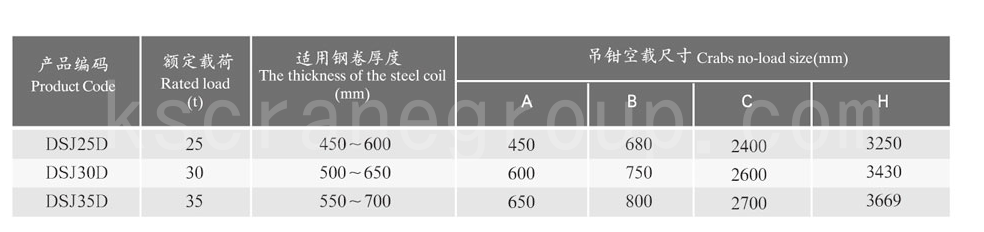

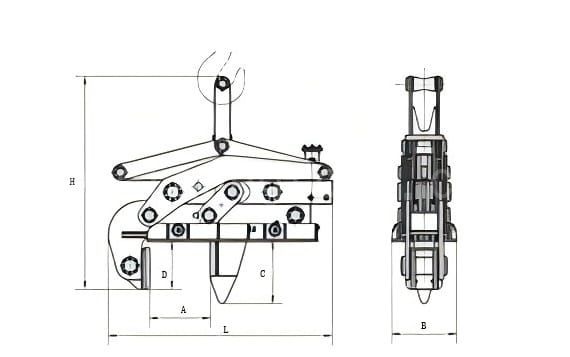

Automatic Vertical Coil Tongs

Self-closing vertical coil clamp is a special lifting spreader for loading, unloading and transportation of vertical coils. Hanging on the single hook crane, relying on open and close the clamp or clamping steel coil, without external power, safe and reliable.

- Low spreader cost

- The spacing of the steel coil stacking, or lifting order of the limitations of the requirements are not obvious

- However, it needs the cooperation of ground personnel, and the operation efficiency is low.

The shape and installation dimensions are shown below, and it can be designed according to the user’s requirements.

| Load(T) | Tong parameter(mm) | Self weight(kg) | |||||

| A | B | C | D | H | L | ||

| 20 | 200-525 | 650 | 650 | 450 | 2200-3500 | 2400 | 5000 |

| 30 | 250-600 | 700 | 750 | 550 | 2400-4300 | 2700 | 7000 |

| 45 | 250-800 | 850 | 800 | 600 | 2600-5600 | 2900 | 10000 |

Daily Maintenance

After use, the spreader must be put on a special rack, stored in a ventilated, dry and clean plant, and kept by a special person.

The surface of the spreader should be protected against rust frequently, and it is not allowed to be stored in acid, alkali, salt, chemical gas and humid environment.

The spreader is prohibited to be stored in the high temperature area, if high temperature lifting is needed, there are special high temperature resistant products

Clean the rotating parts regularly and lubricate them regularly to prevent dry friction and jamming phenomenon.

Electrical parts must be tested regularly, no corrosion of cable skin, reliable contact of connectors and components.

Caution

Suspension mounting and hanging operations shall be performed by a suspension mounting and hanging operations qualified person.

Use the appropriate type of machine for the purpose.

Use within the allowable load range.

Use within the allowable plate thickness.

Do not enter the area where the load is falling or overturning.

Do not move or stop the load sharply.

Do not stay in mid-air for a long period of time while the load is being lifted.

Get in Touch

- Free and fast quote for the product.

- Provide you our product catalog.

- Your local crane projects from our company.

- Become our agent and earn commission.

- Any questions, contact us.

.png?w=200&h=134)