- EQUIPMENT

-

special cranes

-

Garbage Grab Crane

-

Foundry Overhead Crane

-

Explosion-proof Overhead Crane

-

Tongs Overhead Crane

-

Overhead Crane with Carrier-beam

-

Electromagnetic Overhead Cranes

-

Diesel Hydraulic Straddle Carrier: Flexible Operation and Affordable Solution for Container Handling

-

Upper Spillway Gate Gantry Crane: Reliable Solution for Dam Gate Hoisting and Hydropower Station Operations

-

Harbour Portal Crane: Powerful and Intelligent Solutions for Efficient Port Handling

-

Coke Pot Crane for CDQ: Exceptional Heavy-Duty Red-Hot Coke Handling

-

Emergency Rescue Specialized Crane for Water-Rescue Simulation: Engineered for Lifesaving Training

-

Intelligent Grab Bucket Overhead Crane: Powerful, Precise and Unmanned Bulk Material Handling Solution

-

Custom Multi-Point Suspension Overhead Crane for Large-Span and Load-Sensitive Industrial Buildings

-

Electrolytic Copper Cranes: Specialized in Efficient Cathode Plate Tank Loading and Transfer

-

Nuclear Polar Cranes: Multi-Function Lifting Machinery For Nuclear Power Plants

-

-

Industry Crane

-

Industry Crane

-

Tundish Cranes

-

Slab Cranes

-

Scrap Cranes

-

Billet Cranes

-

Coil,Bar and Plate Handling Cranes

-

Cement And Precast Crane

-

Power Station Crane

-

Ladle Cranes

-

Paper Industry Cranes

-

Waste to Energy Cranes and Biomass Cranes

-

Tailored Overhead Cranes for Aerospace: High Precision, Efficience, Safety and Reliability

-

Anode Baking Multifunctional Cranes: Versatile, High-Temp Resistant & Smart-Controlled Must-Have for Electrolytic Aluminum Industry

-

Multifunctional Crane For Electrolytic Aluminum: Fulfills All Aluminum Electrolysis Processes, Boosts Plant Efficiency

-

Warehouse Stacker Crane for AS/RS: High-Efficiency, Reliable, Fully Automated Storage

-

Slab Handling Overhead Crane: Metallurgical-Grade Crane for Continuous Casting and Slab Yards

-

Anode Carbon Block Stacking Cranes: 6-Layer Stacking, A Lifting Solution for Carbon Plants’ Efficient Transfer

-

Quenching Crane for Heat Treatment: Process-Oriented Overhead Crane Solution

-

Safe & Stable Scrap Charging Overhead Crane for Metallurgical Feeding Operations

-

Forging Overhead Crane: Reliable Lifting Equipment for Heavy-Duty Forging Workshops

-

Mold Handling Crane for AAC Production Line: Reliable Engineered Fixed-Position Lifting Solution

-

-

Hoist & Winch Trolley

-

Casting Electric Wire Rope Hoist

-

European Model Electric Hoist

-

Explosion-proof Electric Hoist

-

Low-headroom Electric Hoist

-

Electric Chain Hoist

-

2 Types Explosion-Proof Electric Chain Hoists for Hazardous Zones: Gas & Dust Protection

-

2 Types Explosion-Proof Electric Wire Rope Hoists for Industrial Safety: Reliable Gas & Dust-Proof Solutions

-

Manual Hoists for Precision Lifting: Explore 3 Proven Types for Power-Free Operation

-

Air Pneumatic Hoists: 4 Specialized Designs for Precision, Safety, and Harsh Environments

-

HC Type Electric Hoist: Heavy-duty Wire Rope Hoist for Factory Heavy Lifting

-

-

CRANE Spreader

-

Crane Electromagnetic Lifting Magnets

-

Lifting Electromagnet for Turning and Side Hung

-

Lifting Electromagnet for Thick Plate

-

Specialized Electromagnet for Lifting Steel Plates

-

Lifting Electromagnets for Lifting Steel Plates

-

Lifting Electromagnet for Heavy Rail and Profiled Steel

-

Lifting Electromagnet for High Speed Wier(Coiled Bar)

-

Lifting Electromagnet for Rebar and Steel Pipe

-

Lifting Electromagnet for Bundled Rebar and Profiled Steel

-

Lifting Electromagnet for Billet, Girder Billet and Slab

-

Lifting Electromagnet for Steel Scraps

-

- Crane Spreader

- Crane Hook

- Crane Lifting Tongs and Clamps

-

Crane Electromagnetic Lifting Magnets

- CRANE PARTS

- Transfer Cart

Monorail Overhead Cranes: For Flexible Track Layouts

What is a monorail overhead travelling crane

Monorail overhead cranes are a type of overhead crane designed to transport heavy loads along a single horizontal track. Unlike conventional cranes that rely on a fixed rail system, an overhead monorail crane operates along a single, uninterrupted path and is usually mounted on a ceiling, rail or other frame.

Parameters of monorail overhead crane

Lifting weight: 0.5-16t; according to the roof’s bearing capacity to determine, can be customized according to the need for non-standard products

Lifting height: 6m-30m, Can be customized to your needs

Working environment: working environment temperature -20 ℃ ~ +40 ℃ without flammable, explosive hazards and corrosive media environmental conditions

Trolley traveling speed: 20-30m/min.

Working duty: M3

Monorail Overhead Cranes Price

| Lift capacity | Hoist | Lift height/m | Track model | Price/USD |

| 0.5 ton | CD type | 6-18 | 16-28b | 345-640 |

| 1 ton | CD type | 6-30 | 16-28b | 350-655 |

| 2 ton | CD type | 6-30 | 20-32a | 450-730 |

| 3 ton | CD type | 6-30 | 20-32a | 460-740 |

| 5 ton | CD type | 6-30 | 25a-63c | 600-1665 |

| 10 ton | CD type | 9-30 | 28a-63c | 775-1820 |

| Lift capacity | Hoist | Lift height/m | Track model | Price/USD |

| 0.5 ton | MD type | 6-18 | 16-28b | 380-680 |

| 1 ton | MD type | 6-30 | 16-28b | 400-705 |

| 2 ton | MD type | 6-30 | 20-32a | 500-865 |

| 3 ton | MD type | 6-30 | 20-32a | 520-890 |

| 5 ton | MD type | 6-30 | 25a-63c | 660-1720 |

| 10 ton | MD type | 9-30 | 28a-63c | 895-1940 |

Main components of monorail overhead cranes

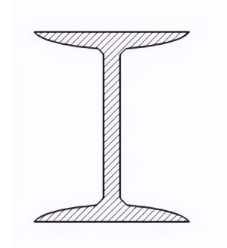

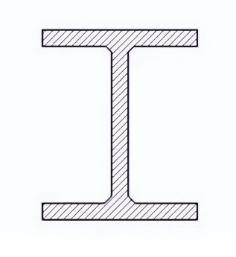

Traveling Rails: Unlike conventional overhead cranes that use multiple girders, monorail bridge cranes typically run on rails consisting of I-beams or H-beams. This structural design allows the trolley to move horizontally in the direction of the monorail, providing efficient and precise material handling.

The difference between H-beam and I-beam:

Flange cross-section: I-beam flange cross-section of thin outside and thick inside, H-beam flange cross-section is equal.

Stability: I-beam trolley walking surface is narrower, H-beam trolley walking surface can be widened, more stable during heavy load operation.

Widely used: I-beam is more widely used, can be equipped with CD, MD-type hoist; H-beam has certain limitations, usually equipped with European hoist when used

Production process: I-beams are rolled once, H-beams can be rolled and welded.

Monorail overhead crane track can also choose cold rolled light rail structure, this track form compared to the I-beam and H-beam more lightweight, easy to install, the use of nylon rubber-coated wheelset, running low noise, more wear-resistant, wheel life cycle is long, low replacement frequency. But the bearing capacity is limited, generally applicable to less than 2 tons of working conditions.

Traveling trolley: The trolley of a monorail overhead travelling crane refers to the hoist running trolley. The travelling trolley moves horizontally along the direction of the main girder and the loaded weight moves to achieve precise positioning during the lifting and transportation operations. Equipped with CD and MD hoists that can be suspended underneath the I-beam, and with European-style hoists when the corresponding rail profile is selected as H-beam, the hoist runs on the lower flange plate of the H-beam, and equipping the European-style hoists is conducive to increasing the lifting height.

CD type electric hoist

MD type electric hoist

Hand Chain Pulley Block

Electric chain hoist

European Model Electric Hoist

Runway Support: Monorail overhead cranes are supported by a runway system, which can be either ceiling-mounted or freestanding steel, depending on the layout of the facility and specific operational needs. The runway supports the main beams and ensures the smooth movement of the trolleys and lifts along their designated paths.

Ceiling-mounted

Freestanding

Advantages of Monorail Overhead Cranes over Other Cranes

Cost-effectiveness: Monorail crane systems are one of the most cost-effective crane systems. Because monorail cranes do not require the laying of multiple traveled tracks and have no end-beam devices, less steel is used and costs less. Another price consideration is that monorail overhead cranes typically require less maintenance than bridge cranes. This means they generally have lower long-term operating costs compared to bridge cranes.

Flexibility and maneuverability: With its unique single-track design, a monorail overhead crane can operate in confined spaces, such as narrow assembly lines or warehouse aisles, and follow complex paths that can be diverted to change the work path. Depending on the applicable situation, it can travel along straight lines, or design curves and loops. Curved track running than straight line running optimizes the operating time, specifically reflected in the can effectively bypass obstacles (such as equipment, columns or building structures, etc.), to achieve the transfer between the span, avoiding the traditional straight line track need to stop several times, change direction or manual intervention, thus enhancing operational efficiency. Multiple lifting hoists can be hung on the traveling track as needed.

High utilization of effective space: monorail overhead travelling crane is mostly installed at the top of the building, which is more compact compared with traditional cranes, the hook distance from the top of the building is small, and the upper limit size is small, so it can be operated more closely and the lifting height is higher, which increases the effective operating space of the factory. For new factories, it can be designed smaller and more functional.

Diversified drive mode: it can flexibly choose the drive program according to different load demand, working frequency and budget. In the absence of power supply, lightweight, low-frequency scenarios, you can choose the hand chain hoist; if the requirements of operational efficiency or power supply inconvenience can choose the electric drive hoist for remote control or ground control.

Customization: Functional customized design according to the actual use of working conditions, such as under the hook to add lifting electromagnet, grab, hook scale, small lifting tools (such as special clamp, pneumatic suction cups, etc.) and other devices to achieve the special needs of the work. When hanging multiple hoists, infrared sensors can be added to realize the anti-collision function and enhance the safety of operation.

Is a monorail overhead crane right for my shop?

If you don’t know whether to choose monorail overhead travelling crane or not, you can give priority to use monorail overhead travelling crane in the following cases.

1. When the working area is indoor, the ground does not have the condition of track laying, but the top of the plant has a load-bearing structure, you can choose the monorail overhead travelling crane.

2. Fixed-path, long-distance, multi-workshop transfer. Such as warehouses, workshops, long-distance transportation of materials (from loading and unloading area to storage area), monorail overhead travelling crane can realize efficient operation.

3. Process standardization, if the workflow is fixed, do not need too much lateral adjustment, monorail crane is the most concise and effective choice.

4. Need to set the track path according to the direction of the plant production line, especially when the direction of the production line is not straight, the choice of monorail overhead travelling crane is the optimal choice.

The actual selection needs to consider the following key factors: the top of the plant carrying capacity, rated lifting capacity, track layout, lifting height, operating environment characteristics and site-specific engineering parameters.

Applicable Industries

Monorail overhead cranes are used in a wide range of industries. Mining has extensive experience in the manufacture of monorail overhead cranes and is supported by a global after-sales service network. In the past, we have customized a number of monorail overhead cranes for a variety of industries in different regions. These industries include distribution and warehousing, manufacturing and assembly, and construction.

Distribution and warehousing

In warehouses and distribution centers, monorail overhead cranes can be used to move goods from one location to another, the operation can be through the narrow space, used in warehouses to achieve the inter-transfer between the lifting and movement of heavy items to the storage racks, which is usually a fixed line, the use of bridge monorail cranes will significantly improve work efficiency.

Manufacturing and assembly

Monorail overhead cranes are usually used in the manufacturing industry and assembly lines, they can move parts and products from one site to another along a fixed path. This includes transportation of materials to the production line. Monorail overhead cranes can also be used as an alternative to material handling where bridge cranes cannot be accommodated. Monorail overhead cranes are also suitable for handling large and heavy items. They are cost-effective and easy to install and maintain.

Mining

Monorail overhead cranes also play an important role in the mining industry, for example, in coal mines, metal mines to transport equipment, materials or ores can choose 5t monorail overhead cranes, monorail design can be adapted to the narrow tunnel environment. In mine tunneling construction, monorail overhead cranes run on tracks suspended from the top of the roadway without occupying ground space.

Get in Touch

- Free and fast quote for the product.

- Provide you our product catalog.

- Your local crane projects from our company.

- Become our agent and earn commission.

- Any questions, contact us.

.png?w=200&h=134)