- EQUIPMENT

-

special cranes

-

Garbage Grab Crane

-

Foundry Overhead Crane

-

Explosion-proof Overhead Crane

-

Tongs Overhead Crane

-

Overhead Crane with Carrier-beam

-

Electromagnetic Overhead Cranes

-

Diesel Hydraulic Straddle Carrier: Flexible Operation and Affordable Solution for Container Handling

-

Upper Spillway Gate Gantry Crane: Reliable Solution for Dam Gate Hoisting and Hydropower Station Operations

-

Harbour Portal Crane: Powerful and Intelligent Solutions for Efficient Port Handling

-

Coke Pot Crane for CDQ: Exceptional Heavy-Duty Red-Hot Coke Handling

-

Emergency Rescue Specialized Crane for Water-Rescue Simulation: Engineered for Lifesaving Training

-

Intelligent Grab Bucket Overhead Crane: Powerful, Precise and Unmanned Bulk Material Handling Solution

-

Custom Multi-Point Suspension Overhead Crane for Large-Span and Load-Sensitive Industrial Buildings

-

Electrolytic Copper Cranes: Specialized in Efficient Cathode Plate Tank Loading and Transfer

-

Nuclear Polar Cranes: Multi-Function Lifting Machinery For Nuclear Power Plants

-

-

Industry Crane

-

Industry Crane

-

Tundish Cranes

-

Slab Cranes

-

Scrap Cranes

-

Billet Cranes

-

Coil,Bar and Plate Handling Cranes

-

Cement And Precast Crane

-

Power Station Crane

-

Ladle Cranes

-

Paper Industry Cranes

-

Waste to Energy Cranes and Biomass Cranes

-

Tailored Overhead Cranes for Aerospace: High Precision, Efficience, Safety and Reliability

-

Anode Baking Multifunctional Cranes: Versatile, High-Temp Resistant & Smart-Controlled Must-Have for Electrolytic Aluminum Industry

-

Multifunctional Crane For Electrolytic Aluminum: Fulfills All Aluminum Electrolysis Processes, Boosts Plant Efficiency

-

Warehouse Stacker Crane for AS/RS: High-Efficiency, Reliable, Fully Automated Storage

-

Slab Handling Overhead Crane: Metallurgical-Grade Crane for Continuous Casting and Slab Yards

-

Anode Carbon Block Stacking Cranes: 6-Layer Stacking, A Lifting Solution for Carbon Plants’ Efficient Transfer

-

Quenching Crane for Heat Treatment: Process-Oriented Overhead Crane Solution

-

Safe & Stable Scrap Charging Overhead Crane for Metallurgical Feeding Operations

-

Forging Overhead Crane: Reliable Lifting Equipment for Heavy-Duty Forging Workshops

-

Mold Handling Crane for AAC Production Line: Reliable Engineered Fixed-Position Lifting Solution

-

-

Hoist & Winch Trolley

-

Casting Electric Wire Rope Hoist

-

European Model Electric Hoist

-

Explosion-proof Electric Hoist

-

Low-headroom Electric Hoist

-

Electric Chain Hoist

-

2 Types Explosion-Proof Electric Chain Hoists for Hazardous Zones: Gas & Dust Protection

-

2 Types Explosion-Proof Electric Wire Rope Hoists for Industrial Safety: Reliable Gas & Dust-Proof Solutions

-

Manual Hoists for Precision Lifting: Explore 3 Proven Types for Power-Free Operation

-

Air Pneumatic Hoists: 4 Specialized Designs for Precision, Safety, and Harsh Environments

-

HC Type Electric Hoist: Heavy-duty Wire Rope Hoist for Factory Heavy Lifting

-

-

CRANE Spreader

-

Crane Electromagnetic Lifting Magnets

-

Lifting Electromagnet for Turning and Side Hung

-

Lifting Electromagnet for Thick Plate

-

Specialized Electromagnet for Lifting Steel Plates

-

Lifting Electromagnets for Lifting Steel Plates

-

Lifting Electromagnet for Heavy Rail and Profiled Steel

-

Lifting Electromagnet for High Speed Wier(Coiled Bar)

-

Lifting Electromagnet for Rebar and Steel Pipe

-

Lifting Electromagnet for Bundled Rebar and Profiled Steel

-

Lifting Electromagnet for Billet, Girder Billet and Slab

-

Lifting Electromagnet for Steel Scraps

-

- Crane Spreader

- Crane Hook

- Crane Lifting Tongs and Clamps

-

Crane Electromagnetic Lifting Magnets

- CRANE PARTS

- Transfer Cart

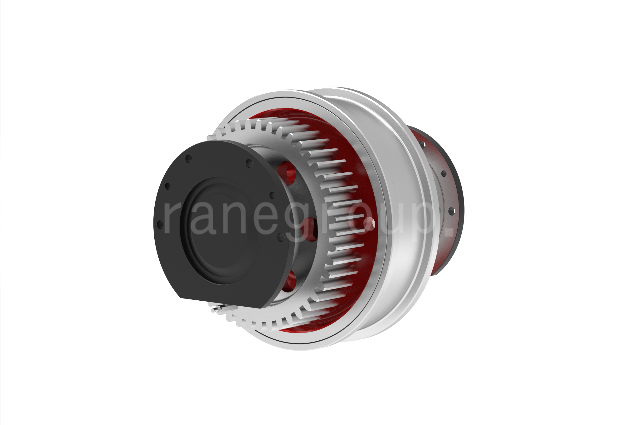

Port Crane Wheel Block Assembly Explained: Structure, Types, and Selection Guide for Port Cranes

Port crane wheel is an important component of port lifting equipment, such as container cranes, portal cranes, ship-to-shore cranes, and shipbuilding gantry cranes. The wheels undertake core tasks, including supporting the weight of the entire machine, guiding track operation, and transmitting driving force.

Portal Crane

In the port working environment characterized by high humidity, salt spray corrosion, and frequent starting and stopping under heavy loads, the wheels must possess characteristics of high strength, high wear resistance, and corrosion resistance.

Port Crane Wheel Block Assembly Structure and Types

Port cranes undertake extremely high loads and continuous operation tasks in daily operation. Whether the traveling mechanism can be stable and reliable depends crucially on the structural design and manufacturing precision of the wheel block assembly.

The wheel block assembly is a modular structural unit that organically combines the wheel, shaft, bearing, bearing housing, and mounting support, responsible for achieving core functions such as load transmission, operation guidance, and power transmission.

According to structural form and application characteristics, the commonly used wheel block assemblies for port cranes can be divided into the following categories:

Parameters and Specifications Display

The common port crane wheel diameter range is Φ400mm–Φ1000mm. Specific parameters (such as wheel width, shaft diameter, and load-bearing capacity) can be consulted in detail in the technical PDF.

L Block Crane Wheel Assembly

The L-type wheel block assembly adopts an integral welded structure, with the bearing housing and mounting base forming an “L” shaped arrangement. Its structure is compact, lightweight, and reasonably stressed, commonly used in small and medium tonnage gantry or bridge cranes.

The bearing housing is equipped with high-strength roller bearings and labyrinth seals to prevent dust and moisture intrusion. The wheel is forged from 42CrMo or ZG50SiMn, and after heat treatment, it has high surface hardness and excellent wear resistance.

Performance Advantages:

- Simple installation and convenient maintenance, can be directly connected to the reducer for use;

- Strong support rigidity and smooth operation;

- Modular design with high adaptability, suitable for both cart and trolley running mechanisms.

Application Scenarios:

The L-type wheel block assembly is commonly found in equipment such as RMG container gantry cranes, shipbuilding gantry cranes, ship-to-shore cranes, and portal cranes, especially suitable for medium-load conditions and high-frequency operation environments.

45° Split Bearing Box Crane Wheel Assembly

This type of wheel block assembly adopts a 45° inclined split bearing housing design, where the upper and lower halves are fixed by bolts, allowing inspection and replacement of bearings without disassembling the entire wheel block assembly.

This structure is widely used in large port cranes and continuous operation equipment, significantly reducing maintenance time and improving operational continuity.

Performance Advantages:

- Convenient maintenance, reducing downtime;

- Reasonable bearing arrangement, uniform stress distribution, and strong impact resistance;

- The wheel body mostly uses ZG340–640 or 42CrMo material, with superior fatigue resistance;

- Gear rings can be customized and added according to driven end or driving end requirements.

Application Scenarios:

Suitable for ship-to-shore container cranes, rail-mounted gantry cranes, ship loaders, ship unloaders, and other equipment, particularly ideal for operating conditions requiring large loads, long travel distances, and high reliability.

Round Bearing Box with Gear Ring Wheel Assembly

On the basis of the round bearing box, an integral forged gear ring structure is added to achieve high-torque direct transmission. The gear ring is integrally machined with the wheel or connected by high-strength bolts, ensuring transmission accuracy and reliability.

This type of wheel block assembly is often used in conjunction with gear reducers and is suitable for low-speed, high-torque drive systems.

Performance Advantages:

- High transmission efficiency, avoiding additional coupling deviations;

- Large load-bearing capacity and stable operation;

- Modular design for quick replacement and maintenance;

- Supports direct motor connection, reducing intermediate transmission links.

Application Scenarios:

Mostly used in ultra-large tonnage equipment such as ship-to-shore cranes, shipbuilding gantry cranes, ship unloaders, and portal cranes, especially suitable for port conditions involving heavy loads, high frequency, and long travel operations.

Round Bearing Box Wheel Assembly

The round bearing box wheel block assembly adopts an integral cylindrical bearing housing structure, featuring high coaxiality and good uniform stress distribution. The bearing housing can be connected to the main beam underframe via bolts or flanges, achieving quick replacement and modular installation.

Its appearance is compact with good sealing, and imported high-precision bearings can be selected internally to support long-term maintenance-free operation.

Performance Advantages:

- High-precision fit, low vibration and low noise;

- Gear transmission system can be added according to working conditions to achieve direct drive;

- High transmission efficiency and smooth operation, suitable for European-style structural cranes.

Application Scenarios:

The round bearing box structure is commonly used in container gantry cranes and shipbuilding gantry cranes. It is especially suitable for work areas with high requirements for operational smoothness and positioning accuracy.

Selection and Customization Guide

When selecting a suitable Port Crane Wheel, it is recommended to comprehensively consider the following factors:

- Load and Operating Frequency: For heavy load and high frequency, it is recommended to select forged steel wheels, with material options of 42CrMo or 65Mn.

- Track Type: Different track types (QU70, QU80, P43) require matching corresponding flange dimensions.

- Usage Environment: Special treatment is required for anti-corrosion, explosion-proof, and dust-proof conditions, such as galvanized or phosphated surfaces.

- Drive Matching: Matching with reducer, bearing housing, and coupling.

KUANGASHAN CRANE Can Provide:

- Non-standard track gauge customization;

- Intelligent wheels with deviation correction and encoder monitoring;

- Multi-layer sealing for dust-proof, waterproof, and salt spray-proof design;

- Optional European standard / national standard interfaces.

Port Crane Wheel Block Assembly Application Cases

KUANGASHAN CRANE’s port crane wheel block assemblies have been successfully applied in multiple global projects:

L Block Crane Wheel Assembly – for 40t portal crane

Conclusion: High-Performance Wheels Enable Efficient Port Cranes

Port crane wheel is the core component for the stable operation of port lifting equipment. High-strength materials, precision machining, and scientific selection not only enhance operational smoothness and service life but also reduce maintenance costs and failure rates.

KUANGASHAN CRANE relies on its integrated production line for independent forging, heat treatment, and precision machining to provide global port customers with reliable, wear-resistant, and customizable port crane wheel solutions.

Get in Touch

- Free and fast quote for the product.

- Provide you our product catalog.

- Your local crane projects from our company.

- Become our agent and earn commission.

- Any questions, contact us.

.png?w=200&h=134)