- EQUIPMENT

-

special cranes

-

Garbage Grab Crane

-

Foundry Overhead Crane

-

Explosion-proof Overhead Crane

-

Tongs Overhead Crane

-

Overhead Crane with Carrier-beam

-

Electromagnetic Overhead Cranes

-

Diesel Hydraulic Straddle Carrier: Flexible Operation and Affordable Solution for Container Handling

-

Upper Spillway Gate Gantry Crane: Reliable Solution for Dam Gate Hoisting and Hydropower Station Operations

-

Harbour Portal Crane: Powerful and Intelligent Solutions for Efficient Port Handling

-

Coke Pot Crane for CDQ: Exceptional Heavy-Duty Red-Hot Coke Handling

-

Emergency Rescue Specialized Crane for Water-Rescue Simulation: Engineered for Lifesaving Training

-

Intelligent Grab Bucket Overhead Crane: Powerful, Precise and Unmanned Bulk Material Handling Solution

-

Custom Multi-Point Suspension Overhead Crane for Large-Span and Load-Sensitive Industrial Buildings

-

Electrolytic Copper Cranes: Specialized in Efficient Cathode Plate Tank Loading and Transfer

-

Nuclear Polar Cranes: Multi-Function Lifting Machinery For Nuclear Power Plants

-

-

Industry Crane

-

Industry Crane

-

Tundish Cranes

-

Slab Cranes

-

Scrap Cranes

-

Billet Cranes

-

Coil,Bar and Plate Handling Cranes

-

Cement And Precast Crane

-

Power Station Crane

-

Ladle Cranes

-

Paper Industry Cranes

-

Waste to Energy Cranes and Biomass Cranes

-

Tailored Overhead Cranes for Aerospace: High Precision, Efficience, Safety and Reliability

-

Anode Baking Multifunctional Cranes: Versatile, High-Temp Resistant & Smart-Controlled Must-Have for Electrolytic Aluminum Industry

-

Multifunctional Crane For Electrolytic Aluminum: Fulfills All Aluminum Electrolysis Processes, Boosts Plant Efficiency

-

Warehouse Stacker Crane for AS/RS: High-Efficiency, Reliable, Fully Automated Storage

-

Slab Handling Overhead Crane: Metallurgical-Grade Crane for Continuous Casting and Slab Yards

-

Anode Carbon Block Stacking Cranes: 6-Layer Stacking, A Lifting Solution for Carbon Plants’ Efficient Transfer

-

Quenching Crane for Heat Treatment: Process-Oriented Overhead Crane Solution

-

Safe & Stable Scrap Charging Overhead Crane for Metallurgical Feeding Operations

-

Forging Overhead Crane: Reliable Lifting Equipment for Heavy-Duty Forging Workshops

-

Mold Handling Crane for AAC Production Line: Reliable Engineered Fixed-Position Lifting Solution

-

-

Hoist & Winch Trolley

-

Casting Electric Wire Rope Hoist

-

European Model Electric Hoist

-

Explosion-proof Electric Hoist

-

Low-headroom Electric Hoist

-

Electric Chain Hoist

-

2 Types Explosion-Proof Electric Chain Hoists for Hazardous Zones: Gas & Dust Protection

-

2 Types Explosion-Proof Electric Wire Rope Hoists for Industrial Safety: Reliable Gas & Dust-Proof Solutions

-

Manual Hoists for Precision Lifting: Explore 3 Proven Types for Power-Free Operation

-

Air Pneumatic Hoists: 4 Specialized Designs for Precision, Safety, and Harsh Environments

-

HC Type Electric Hoist: Heavy-duty Wire Rope Hoist for Factory Heavy Lifting

-

-

CRANE Spreader

-

Crane Electromagnetic Lifting Magnets

-

Lifting Electromagnet for Turning and Side Hung

-

Lifting Electromagnet for Thick Plate

-

Specialized Electromagnet for Lifting Steel Plates

-

Lifting Electromagnets for Lifting Steel Plates

-

Lifting Electromagnet for Heavy Rail and Profiled Steel

-

Lifting Electromagnet for High Speed Wier(Coiled Bar)

-

Lifting Electromagnet for Rebar and Steel Pipe

-

Lifting Electromagnet for Bundled Rebar and Profiled Steel

-

Lifting Electromagnet for Billet, Girder Billet and Slab

-

Lifting Electromagnet for Steel Scraps

-

- Crane Spreader

- Crane Hook

- Crane Lifting Tongs and Clamps

-

Crane Electromagnetic Lifting Magnets

- CRANE PARTS

- Transfer Cart

20 Ton Overhead Crane for Sale: Reliable, Durable, and Versatile Industrial Core Equipment

Table of Contents

The 20 ton overhead crane, a common tonnage type in modern industry, is widely recognized as one of the core lifting devices due to its strong load-bearing adaptability and high operational stability. The 20-ton bridge crane is suitable for a wide range of applications, including steel mills, waste incineration plants, construction sites, machine shops, warehouses, and other environments requiring the handling of heavy materials. It can precisely meet specific requirements and efficiently complete material handling tasks.

Below is an introduction to some of our products. If you would like to learn more about our products, please feel free to contact us. Henan Kuangshan Crane is committed to providing you with professional and practical solutions.

20 Ton Bridge Crane Solution

Double Girder Bridge Crane

20 ton LH Top Running Double Girder Overhead Crane with Wire Rope Hoist

Features: Steel wire rope hoist as the lifting mechanism, simple double-beam structure, suitable for small and medium-sized lifting operations.

20 ton Double Girder Overhead Crane with Open Winch Hoist

Features: The lifting mechanism uses a hoist-type trolley, which can carry a larger load.

20 ton Electromagnetic Overhead Cranes

Features: Equipped with different shapes of electromagnets to adapt to a variety of working scenarios.

20 ton FEM standard overhead crane

Features: Lightweight, energy-efficient, environmentally friendly, and maintenance-free design.

20 ton Double Girder Overhead Crane with Grab Bucket

Features: Mainly used for grabbing and handling various types of powdery and granular bulk materials, the grab trolley is equipped with lifting and opening/closing mechanisms.

20 ton Double Girder Steel Mill Ladle Overhead Cranes

Features: Insulation layer at the bottom of the main beam, suitable for working environments with temperatures ranging from -10 to +60 °C.

20 ton Hand Driving Double Beam Overhead Crane

Features: Suitable for low-volume handling or power-free scenarios, with relatively low operating speed and work efficiency.

Single Girder Bridge Crane

20 ton LD Top Running Single Girder Overhead Crane

Features: Simple and lightweight structure, easy to install and maintain.

20 ton LB Explosion-proof Single Girder Overhead Cranes

Features: The electrical system has been explosion-proof treated and can operate safely in environments containing explosive mixtures.

20 ton LDC Single Girder Low Headroom Overhead Crane

Features: Suitable for work scenarios with limited factory clearance and specific lifting height requirements.

20 ton LDP Single Girder Offset Overhead Crane

Features: The electric hoist is installed on the side of the main beam, significantly expanding the hook’s working space.

The Price Of A 20 Ton Bridge Crane and Factors Affecting

The cost of a 20-ton bridge crane may depend on various factors, such as the type of crane selected, its functionality, installation and maintenance service fees, and accompanying lifting equipment. Typically, the cost of a 20-ton overhead crane can range from several thousand dollars to hundreds of thousands of dollars. For example, a standard 20-ton LD single-beam bridge crane may cost approximately $7,000 to $38,000 depending on the span, while a more advanced double-beam 20-ton overhead crane with additional features may be more expensive.

The following factors may affect the price of a 20-ton bridge crane, including:

- Bridge crane span: The longer the crane span, the higher the material costs and process requirements, resulting in a corresponding increase in price.

- Crane type: Cranes with different structural designs (such as single-beam, double-beam, European standard, etc.) have significant price differences due to variations in drive systems, safety features, and other design elements.

- Lifting height: As lifting height increases, the main beam must be correspondingly extended to ensure load-bearing capacity and stability at higher heights, and appropriate grade steel must be used. Additionally, the power of the lifting motor and components such as wire rope hoists must be appropriately matched.

- Optional features, such as laser anti-sway systems and infrared collision prevention devices, can significantly enhance operational safety and efficiency, effectively prevent crane accidents, and provide strong support for achieving “unmanned, intelligent operation.”

- Customized products: If customization is required based on specific operational needs, this will impact production schedules, delivery timelines, and product pricing.

Whether you are looking for a 20 ton overhead crane for sale or detailed pricing information for a 20 ton EOT crane, we can help. Below is the price range for 20-ton bridge cranes to help you quickly understand the cost of common configurations. Crane products vary greatly in price due to differences in application conditions and configurations. Please contact our engineering consultants for a customized quotation.

Double Girder Overhead Crane

| Product | Span | Lifting Height | Power Voltage | Working Class | Price |

| 20 tonTop Running Double Girder Overhead Crane with Wire Rope Hoist | 10.5-31.5m | 9-12m | 380V 50Hz three-phase | A3-A4 | $14766-38489 |

| 10.5-31.5m | <14m | 380V 50Hz three-phase | A5-A6 | Customized Pricing | |

| 10.5-31.5m | <14m | 380V 50Hz three-phase | A6 | Customized Pricing | |

| 9.5-20m | 6-18m | 380V 50Hz three-phase | A4 | Customized Pricing | |

| 20 ton Double Girder Overhead Crane with Grab Bucket | 16.5-31.5m | <26m | 380V 50Hz three-phase | A6 | Customized Pricing |

| 20 ton Double Girder Steel Mill Ladle Cranes | 10.5-31.5m | <14m | 380V 50Hz three-phase | – | Customized Pricing |

| 20 ton Hand Driving Double Beam Crane | 10~17m | 10-16m | – | A1-A3 | $2684-5368 |

| Product | Span | Lifting Height | Power voltage | Working Class | Price |

| 20 ton LD Top Running Single Girder Overhead Crane | 7.5-25.5m | 9-30m | 380V 50Hz three-phase | A3 | $6712-13467 |

| 20 ton LB Explosion-proof Single Girder Overhead Cranes | 7.5-25.5m | 6-24m | 380V 50Hz three-phase | A3 | $4698-10773 |

| 20 ton LDC Single Girder Low Headroom Overhead Crane | 7.5-21.5m | customized | 380V 50Hz three-phase | A3 | $7047-14140 |

| 20 ton LDP Single Girder Offset Overhead Crane | 7.5- 22.5m | customized | 380V 50Hz three-phase | A3 | $10739-24240 |

Application Industries And Scenarios Of 20-Ton Bridge Cranes

Steel Mill Transportation

20-ton bridge cranes are mainly responsible for lifting and transporting rolled steel coils and steel billets in steel mills, covering material transportation from production workshops to storage areas, ensuring the efficient and safe transfer of steel coils and steel billets during hot rolling, cold rolling, or subsequent processing, while also supporting equipment maintenance and logistics operations

Petrochemical Energy (Equipment Maintenance)

In the oil and gas industry, 20 ton overhead cranes are mainly used for heavy equipment and material handling in scenarios such as drilling rigs, refineries, and pipelines. Their core functions include lifting heavy parts such as pumps, valves, and pipeline components, as well as assisting with equipment maintenance and component replacement.

Construction

A 20 ton bridge crane is used at the construction site to lift and move heavy objects such as steel beams, concrete blocks, and pipes.

Waste Incineration Plant

A 20 ton bridge crane can grab, stack, mix, and feed more than 10 tons of garbage at a time in a large waste incineration plant. A large waste incineration plant can process 4,200 tons of garbage per day. After processing, the household waste is converted into nearly 600 million kilowatt-hours of green electricity, which can meet the annual electricity consumption of approximately 500,000 households.

Warehouse Logistics

20 ton bridge cranes play a central role in the heavy-duty material handling of warehouses, factories, and yards: they efficiently load and unload large goods and efficiently and accurately transfer materials in dedicated yards.

Aerospace Assembly

The 20 ton bridge crane is suitable for aircraft assembly with a load requirement of 10 tons or more. It can lift and transport heavy components such as fuselages, wings, and engines, and accurately position them for assembly. It can also transport components across regions and assist in adjusting the posture of components. With its structural rigidity and precise control, it supports process alignment, differential rotation, and synchronous multi-point lifting, comprehensively ensuring assembly accuracy, efficiency, and safety.

20 Ton Overhead Crane Selection Guide

When selecting a bridge crane, it is crucial to accurately assess your needs and the performance of the equipment. The following are some factors to consider when purchasing a bridge crane:

- Determine the lifting capacity: Clearly define the maximum load to select the main beam structure and hoist type.

- Define the operating environment: For outdoor use, consider surface corrosion protection; pay attention to environmental temperature—in high-altitude, low-temperature environments, prevent brittle fracture of steel materials, and in high-temperature environments, consider high-temperature resistant design; for special environments, such as those with explosive gas mixtures, determine the protection rating, material selection for components, and explosion-proof configuration of the electrical system.

- Crane span: Determine the optimal span based on factory dimensions, column positions, and the required coverage area of the work zone.

- Key configurations: Optional configurations include variable frequency systems, travel limit switches, overload protection, collision prevention systems, remote monitoring, and automated operation to enhance operational safety and precision.

- Compliance and certifications: Confirm that the manufacturer provides products compliant with local standards and quality management requirements, and holds a special equipment manufacturing license.

- Maintenance and servicing: In addition to the crane itself, regular inspections and maintenance are required during installation and use. It is important to clarify whether related services are included.

The selection of a bridge crane is a comprehensive decision-making process that must consider factors such as lifting capacity, span, duty cycle, operating speed, installation space, environmental conditions, and cost. Only through scientific and reasonable selection can the chosen equipment efficiently and safely serve production, creating greater value for the enterprise.

Henan Kuangshan Exports 20 Ton Overhead Crane Industry Case Study

20 Ton Bridge Crane Exported to Bangladesh

A new client in Bangladesh required repairs for old equipment purchased from another Henan crane manufacturer and was introduced to us by an existing client. After the old equipment was repaired, the client needed to install a new crane in a small workshop space to lift molds, with dual-speed requirements for both lifting and running speeds. Our engineers thoroughly considered factors such as the workshop space constraints and the dual-speed requirements for mold lifting, engaging in detailed discussions with the client and refining the solution multiple times. Through professional and rigorous technical expertise combined with attentive service, we gained the client’s full approval and secured the order. Equipment specifications:

- Lifting capacity: 20 tons

- Span: 22.35 meters

- Both lifting and running mechanisms are dual-speed

- Motor: Three-in-one motor

- Production cycle: 30 days

- Transportation cycle: 40 days

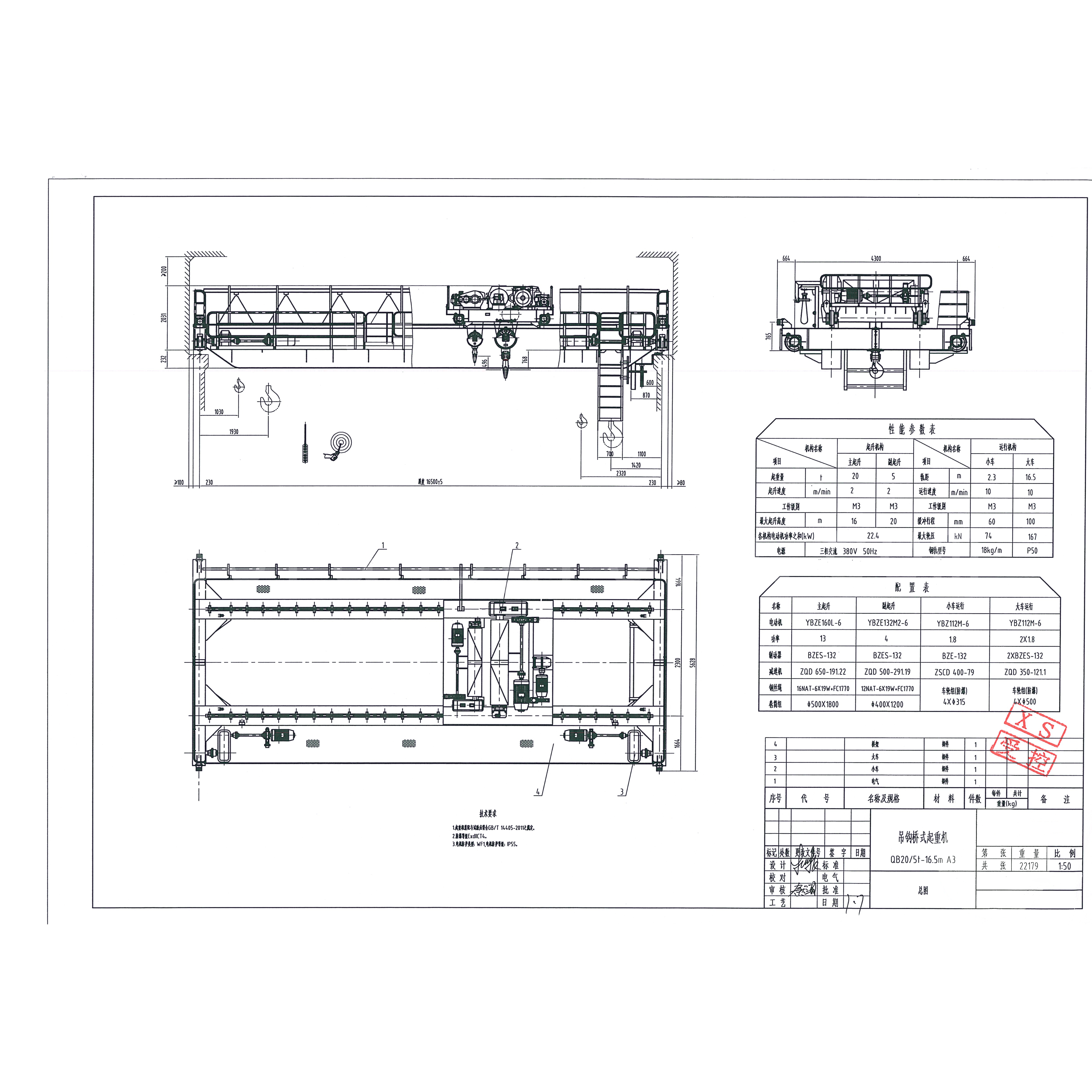

20-Ton QB Explosion-Proof Double Girder Bridge Crane Designed Specifically For The Petrochemical Industry

Commissioned by a client from a petrochemical company, we designed a 20-ton QB explosion-proof double-girder bridge crane for use in production facilities and storage areas within petrochemical plants that involve flammable and explosive media. The crane is used to transport heavy equipment and materials, meeting the explosion-proof operation requirements of the petrochemical industry. The equipment parameters are as follows:

- Product: Explosion-proof double-girder bridge crane

- Lifting capacity: 20t/5t

- Span: 16.5m

- Operation mode: Ground + remote control

- Explosion-proof rating: ExdIICT4

- Motor protection rating: IP55

- Price: $69540

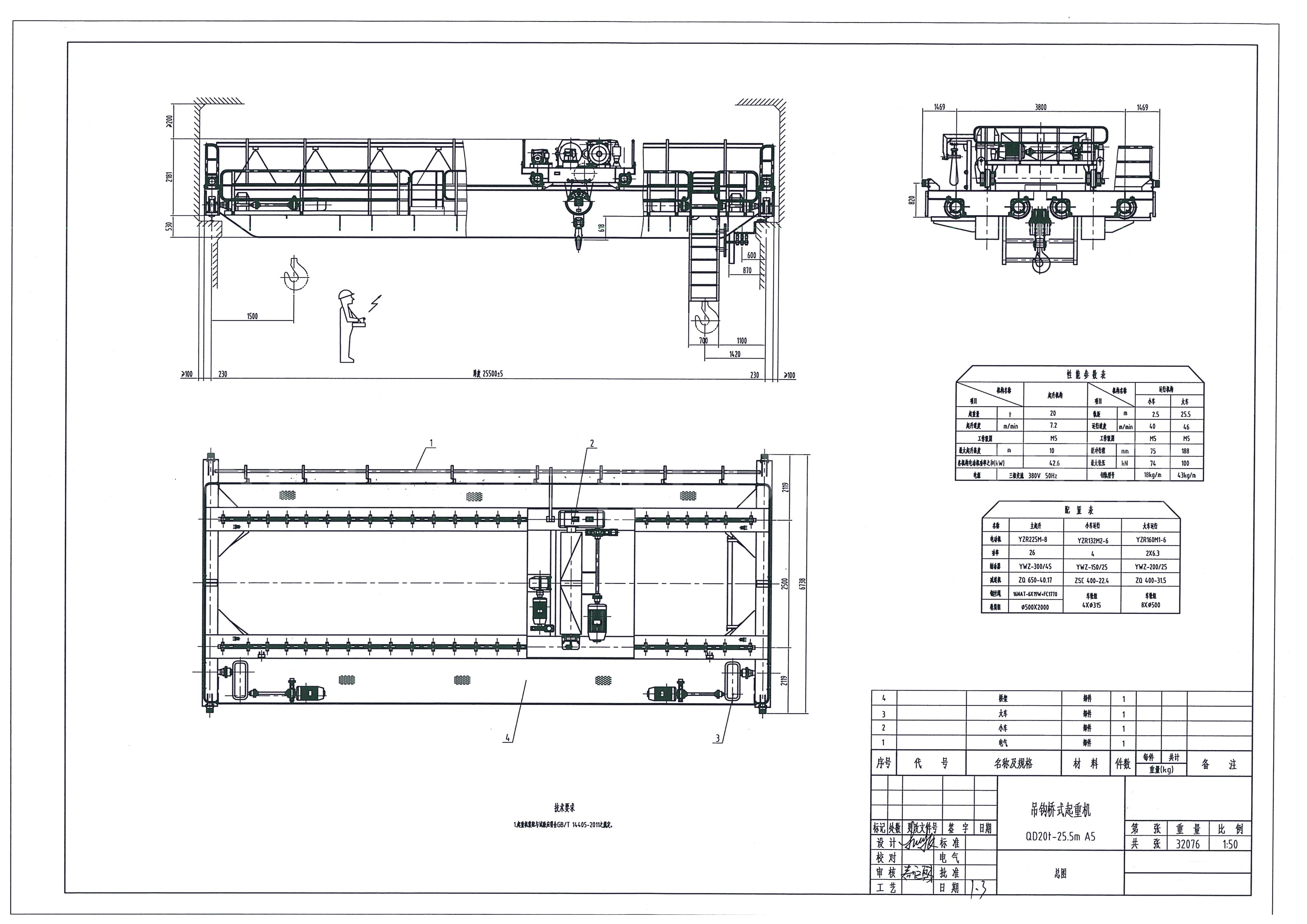

Delivery Of A 20 Ton QD Hook Bridge Crane (Single Hook Type) For The Building Materials Industry

Commissioned by a construction company client, we designed a 20-ton QD hook bridge crane (single hook) for use in building component production workshops, precast component storage yards, and other scenarios, to meet the operational requirements for handling building materials, loading and unloading precast components, and installing and commissioning production equipment. Product specifications are as follows:

Product: QD hook bridge crane (single hook)

- Lifting capacity: 20t

- Span: 25.5m

- Work class: A5

- Operation method: Remote control operation

- Lifting height: 10m

- Price: $30057

Summary

The 20 ton bridge crane, as a core lifting equipment in modern industry, belongs to the larger tonnage category among common bridge cranes. It not only handles the tasks of smaller tonnage cranes but also addresses the material handling needs of larger tonnage loads in the tens of tons range. It offers the advantages of strong adaptability, high processing capacity, and reliable operation, effectively enhancing operational efficiency and reducing manual risks, making it widely suitable for various heavy-duty material handling requirements.

Henan Mining Crane Co., Ltd., with its deep technical expertise and strong manufacturing capabilities, has the capacity to produce large-tonnage bridge cranes ranging from 1 to 550 tons. From 1-ton small-scale workstation cranes for light-duty material handling to 500-ton ultra-large bridge cranes tackling challenging tasks such as lifting large components in the nuclear power sector or handling ultra-heavy molten metal in the metallurgy industry, our product range is extremely broad, making us one of the most reliable bridge crane manufacturers you can trust.

Do you like what we do?Share it

.png?w=200&h=134)