- EQUIPMENT

-

special cranes

-

Garbage Grab Crane

-

Foundry Overhead Crane

-

Explosion-proof Overhead Crane

-

Tongs Overhead Crane

-

Overhead Crane with Carrier-beam

-

Electromagnetic Overhead Cranes

-

Diesel Hydraulic Straddle Carrier: Flexible Operation and Affordable Solution for Container Handling

-

Upper Spillway Gate Gantry Crane: Reliable Solution for Dam Gate Hoisting and Hydropower Station Operations

-

Harbour Portal Crane: Powerful and Intelligent Solutions for Efficient Port Handling

-

Coke Pot Crane for CDQ: Exceptional Heavy-Duty Red-Hot Coke Handling

-

Emergency Rescue Specialized Crane for Water-Rescue Simulation: Engineered for Lifesaving Training

-

Intelligent Grab Bucket Overhead Crane: Powerful, Precise and Unmanned Bulk Material Handling Solution

-

Custom Multi-Point Suspension Overhead Crane for Large-Span and Load-Sensitive Industrial Buildings

-

Electrolytic Copper Cranes: Specialized in Efficient Cathode Plate Tank Loading and Transfer

-

Nuclear Polar Cranes: Multi-Function Lifting Machinery For Nuclear Power Plants

-

-

Industry Crane

-

Industry Crane

-

Tundish Cranes

-

Slab Cranes

-

Scrap Cranes

-

Billet Cranes

-

Coil,Bar and Plate Handling Cranes

-

Cement And Precast Crane

-

Power Station Crane

-

Ladle Cranes

-

Paper Industry Cranes

-

Waste to Energy Cranes and Biomass Cranes

-

Tailored Overhead Cranes for Aerospace: High Precision, Efficience, Safety and Reliability

-

Anode Baking Multifunctional Cranes: Versatile, High-Temp Resistant & Smart-Controlled Must-Have for Electrolytic Aluminum Industry

-

Multifunctional Crane For Electrolytic Aluminum: Fulfills All Aluminum Electrolysis Processes, Boosts Plant Efficiency

-

Warehouse Stacker Crane for AS/RS: High-Efficiency, Reliable, Fully Automated Storage

-

Slab Handling Overhead Crane: Metallurgical-Grade Crane for Continuous Casting and Slab Yards

-

Anode Carbon Block Stacking Cranes: 6-Layer Stacking, A Lifting Solution for Carbon Plants’ Efficient Transfer

-

Quenching Crane for Heat Treatment: Process-Oriented Overhead Crane Solution

-

Safe & Stable Scrap Charging Overhead Crane for Metallurgical Feeding Operations

-

Forging Overhead Crane: Reliable Lifting Equipment for Heavy-Duty Forging Workshops

-

Mold Handling Crane for AAC Production Line: Reliable Engineered Fixed-Position Lifting Solution

-

-

Hoist & Winch Trolley

-

Casting Electric Wire Rope Hoist

-

European Model Electric Hoist

-

Explosion-proof Electric Hoist

-

Low-headroom Electric Hoist

-

Electric Chain Hoist

-

2 Types Explosion-Proof Electric Chain Hoists for Hazardous Zones: Gas & Dust Protection

-

2 Types Explosion-Proof Electric Wire Rope Hoists for Industrial Safety: Reliable Gas & Dust-Proof Solutions

-

Manual Hoists for Precision Lifting: Explore 3 Proven Types for Power-Free Operation

-

Air Pneumatic Hoists: 4 Specialized Designs for Precision, Safety, and Harsh Environments

-

HC Type Electric Hoist: Heavy-duty Wire Rope Hoist for Factory Heavy Lifting

-

-

CRANE Spreader

-

Crane Electromagnetic Lifting Magnets

-

Lifting Electromagnet for Turning and Side Hung

-

Lifting Electromagnet for Thick Plate

-

Specialized Electromagnet for Lifting Steel Plates

-

Lifting Electromagnets for Lifting Steel Plates

-

Lifting Electromagnet for Heavy Rail and Profiled Steel

-

Lifting Electromagnet for High Speed Wier(Coiled Bar)

-

Lifting Electromagnet for Rebar and Steel Pipe

-

Lifting Electromagnet for Bundled Rebar and Profiled Steel

-

Lifting Electromagnet for Billet, Girder Billet and Slab

-

Lifting Electromagnet for Steel Scraps

-

- Crane Spreader

- Crane Hook

- Crane Lifting Tongs and Clamps

-

Crane Electromagnetic Lifting Magnets

- CRANE PARTS

- Transfer Cart

6 Explosion-Proof Overhead Cranes: Maximum Safety in Hazardous Workspaces

Explosion-proof overhead cranes is a type of lifting equipment specifically designed for hazardous environments and is widely used in the chemical, oil & gas, pharmaceutical, aerospace, and other industries for safe and reliable operation.

This equipment adopts an integrated design of explosion-proof motor, explosion-proof electrical control, and spark-proof mechanical structure, complying with international and national explosion-proof standards such as ATEX, IECEx, and GB3836, to ensure safe and efficient operation in flammable and explosive environments.

Whether it is small to medium tonnage single girder lifting, or large-span, heavy-duty double girder explosion-proof hoisting, we can provide customized solutions for our clients.

Types of Explosion-Proof Overhead Cranes

- Lifting capacity: 1t~20t

- Span: 7.5m~22.5m

- Lifting height: 6m~30m

- Working group: A3

- Lifting capacity: 0.5t~16t

- Span: 3m~16m

- Lifting height: 6m~30m

- Working group: A3

- Lifting capacity: 5t~40t

- Span: 7.5m~31.5m

- Lifting height: 6m~30m

- Working group: A3

- Lifting capacity: 5t~200t

- Span: 10.5m~31.5m

- Lifting height: 16m~22m

- Working group: A4

- Lifting capacity: 32t~160t

- Span: 16.5m~28.5m

- Lifting height: 16m~30m

- Working group: A4

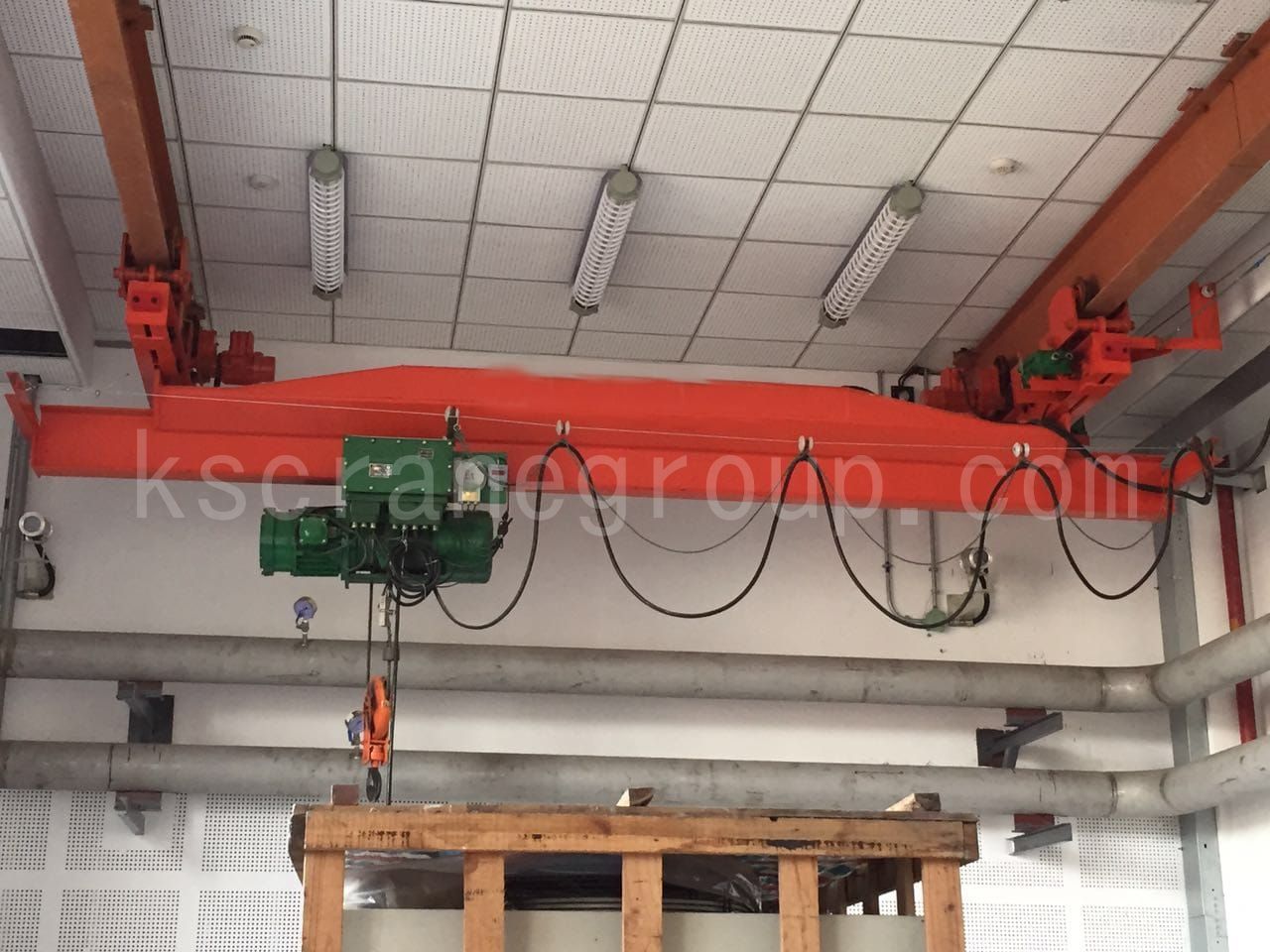

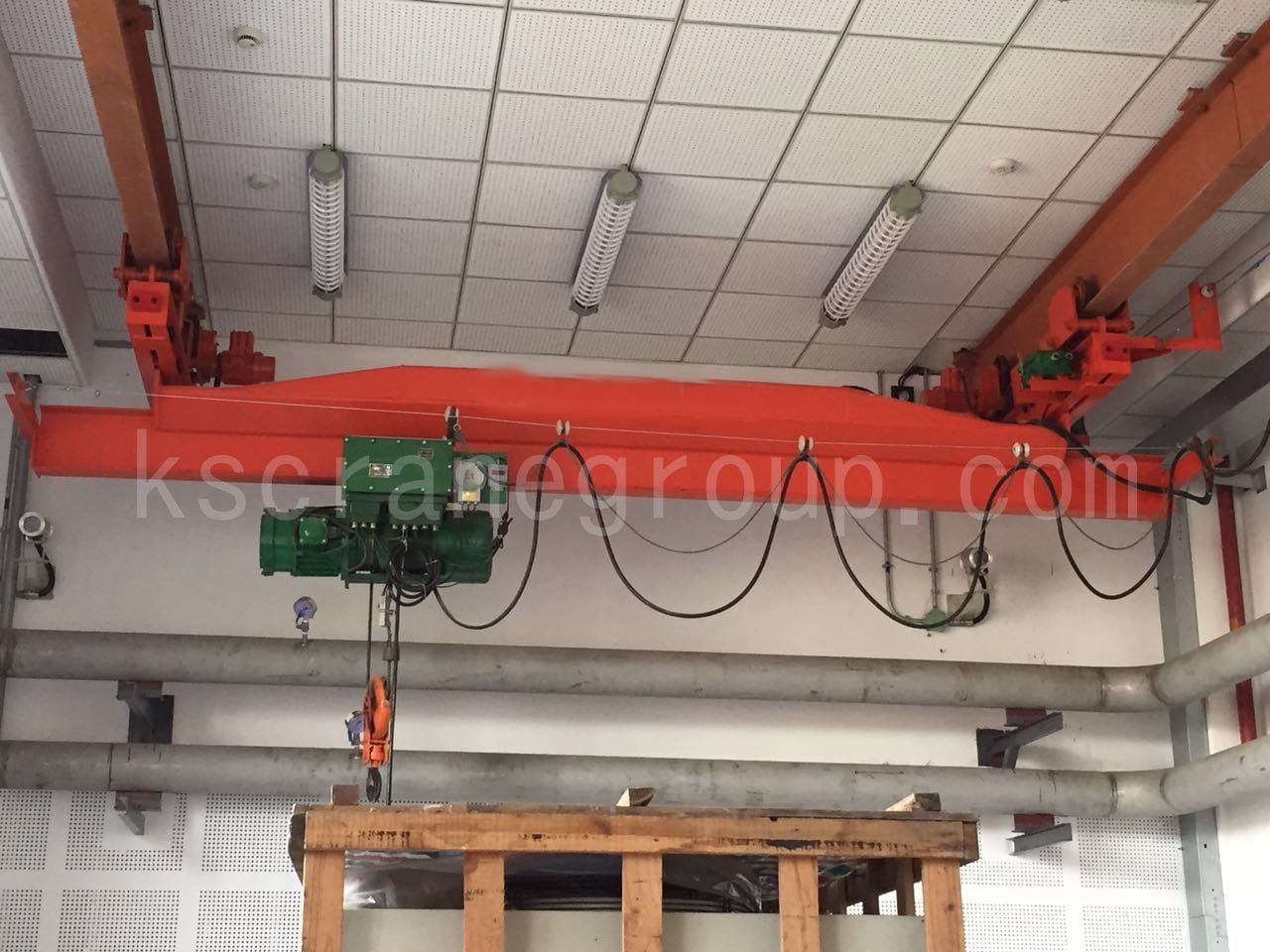

LB Explosion-Proof Single Girder Overhead Crane

LB single girder explosion-proof overhead crane is used in the working environment where explosive mixtures exist. The structure of its main load-bearing components and LD electric single girder overhead cranes are the same. The main difference is that the entire electrical equipment are used in explosion-proof type, and the power supply of the trolley is supplied by flexible cable.

Product Features:

- Compact structure, good rigidity, sensitive operation, low noise, pollution-free, safe and reliable, elegant appearance, and strong explosion-proof performance.

- Suitable for indoor factory environments with ambient temperature -25℃~+40℃ and relative humidity ≤85%.

- The main beam is the main load-bearing component of the hoist-type crane, and its lower flange serves as the running track of the electric hoist.

- The end beam device, also known as the cross beam, is located at both ends of the main beam and is bolted to the main beam through hanging plates. Its structure is mainly formed by welding U-shaped channels rolled from steel plates, lower cover plates, reinforcement plates, and stiffeners.

- The motor adopts BZDY(D) series conical explosion-proof rotor brake motor. The standard motor insulation class is Class B, and the protection grade is IP44. It can also be manufactured into Class F or H insulation, with IP54 or IP55 protection grades according to working conditions.

- The wheel set is forged from 45# steel, and processed by rough turning, quenching, tempering, and finish turning. The heat treatment hardness is 300~380HB, and at a depth of 15mm the hardness is not lower than 260HB. When the explosion-proof grade is ExdⅡCT4, the operating mechanism is treated with spark-proof technology, such as wheel surfacing with stainless steel or bronze.

- Motors and electrical devices are of flameproof type. When the explosion-proof grade is ExdⅡCT4, the operating mechanism is treated with spark-proof measures.

- The enclosure of explosion-proof electrical devices is sealed and firm, with explosion-proof grade ExdIIBT4 or ExdIICT4.

LXB Explosion-Proof Single Girder Underslung Crane

LXB explosion-proof electric single girder underslung crane is used in the working environment where explosive mixtures exist. The structure of its main load-bearing components and LX-type electric single girder underslung cranes are the same. The main difference is that the entire electrical equipment are used in explosion-proof type, and the power supply of the large vehicle is supplied by flexible cable.

Product Features:

- Working environment temperature: -25℃~+40℃, relative humidity ≤85%, explosion-proof area: Zone 1 or Zone 2

- The crane operation mode can be selected as ground operation or remote control operation according to specific conditions, with an operating speed not greater than 25m/min. The operating speed of the crane can also be designed as dual speed or frequency conversion speed regulation.

- The crane operating mechanism adopts separate drive form. Driving and braking are completed by the conical rotor motor, and the transmission adopts the “one open, two closed” gear transmission.

- The electric suspension crane bridge frame is mainly composed of the main beam and end beam device. The main beam is the main load-bearing component of the hoist-type crane, and its lower flange is the running track of the electric hoist.

- The motor adopts the ZDY series conical rotor brake motor. The standard motor insulation class is Class B, and the protection grade is IP44. It can also be made into Class F or H insulation, with protection grade IP54 or IP55 according to working conditions. The explosion-proof grades are ExdⅡBT4 and ExdⅡCT4.

- The wheel set is forged with 45# steel die, and processed through rough turning, quenching, tempering, and finish turning. The heat treatment hardness is 300~380HB, and the hardness at a depth of 15mm after quenching is not less than 260HB. When the explosion-proof grade is ExdⅡCT4, explosion-proof wheels must be used.

- The explosion-proof electrical device housing is tightly sealed, with explosion-proof grade of ExdⅡBT4 and ExdⅡCT4.

LHB Explosion-Proof Double Girder Overhead Crane with hoist

LHB double girder explosion-proof overhead cranes with hoist are used in the working environment where explosive mixtures exist. The structural form of its main load-bearing components is similar to that of LH electric hoist double girder bridge cranes. The main difference is that the whole machine’s electrical equipment is used in an explosion-proof type, and the power supply of the big vehicle adopts a flexible cable type power supply.

Product Features:

- Working environment temperature: –20~+40℃, relative humidity not greater than 90% (at 25℃), altitude not exceeding 1000 m.

- Compact structure, good rigidity, easy operation, low noise, low building clearance height, light self-weight, small wheel pressure, safe and reliable, and beautiful appearance.

- The main beam is an important load-bearing structural part of the crane. This series of cranes adopts a middle-track box-shaped beam. Each main beam is strictly manufactured in accordance with our company's box beam manufacturing process standards from blanking to welding and forming. The main beam material is Q235B; the end beam device, also called the cross beam, adopts a steel plate welded box structure, and the material is Q235B.

- Type A2 fixed high-quality wire rope explosion-proof electric hoist is adopted as the lifting mechanism.

- The motor adopts the BZDY(D) series explosion-proof motor. The standard motor insulation class is Class B, protection grade is IP44, and it can also be made into Class F or H insulation, IP54, or IP55 protection grade according to working conditions. The explosion-proof grades are ExdⅡBT4 and ExdⅡCT4.

- The wheel set is forged with 45# steel die, and processed through rough turning, quenching, tempering, and finish turning. The heat treatment hardness is 300~380HB, and the hardness at a depth of 15mm after quenching is not less than 260HB. When the explosion-proof grade is ExdⅡCT4, explosion-proof wheels must be used to prevent sparks caused by friction with the rail.

- The operation mode is mostly ground operation, with an operating speed generally of 10 m/min or 20 m/min. Remote control operation and cab operation can also be selected according to specific conditions.

- Motors and electrical appliances are explosion-proof type. When the explosion-proof grade is ExdⅡCT4, the operating mechanism shall be treated with anti-spark protection.

- The explosion-proof electrical device housing is tightly sealed, with explosion-proof grade of ExdⅡBT4 and ExdⅡCT4.

QB Explosion-Proof Double Girder Overhead Crane with Open Winch

QB double girder explosion-proof overhead cranes with open winch are used in the working environment where explosive mixtures exist. The structural form of its main load-bearing components is the same as that of ordinary double-girder bridge cranes. The main difference is that the electrical equipment of the whole machine adopts the explosion-proof type, and the power supply of the big vehicle adopts the flexible cable type power supply.

Product Features:

- Double-girder double-rail structure with a single trolley hoist. The main beam adopts a positive rail box-type structure, and the main load-bearing component material of the main beam is Q235-B, with a minimum plate thickness not less than 6 mm.

- The wheel material is special steel for crane wheels, and the tread and inner side of the wheel flange are made of stainless steel or copper alloy to ensure no visible sparks are generated when the wheel contacts the rail.

- The hoisting mechanism motor adopts a special explosion-proof motor for cranes, with a built-in braking function, insulation class F, and protection grade IP55.

- Power supply adopts a trailing flat explosion-proof cable with a galvanized metal sheath.

- The limit switch is an explosion-proof travel switch with explosion-proof grade ExdⅡCT4.

- All mechanical friction parts (wheels, drum) are made of spark-free copper alloy material.

- The electrical box adopts a sealed design, filled with inert gas (nitrogen) for explosion-proof protection.

QBE Explosion-Proof Double Girder Overhead Crane with Double Trolley

QBE double girder explosion-proof overhead cranes with double trolley in the picture is a larger explosion-proof crane equipment in China, used in the aerospace industry. It consists of two 160t lifting explosion-proof trolleys, heavy-duty bridge and three-in-one transportation drive.

Product Features:

- The double trolleys can lift and lower synchronously, enabling synchronized hoisting and workpiece flipping operations, with explosion-proof grade DIICT4.

- Combined with new crane design concepts, the design and manufacturing meet GB national standards and FEM European standards.

- The whole crane adopts a hard-tooth surface reducer, frequency conversion drive, multiple safety protections, simplified structure, and environmentally friendly low energy consumption.

- It can be applied to various explosion-proof or other environments with high safety requirements.

Clean Explosion-Proof Overhead Cranes

This crane is developed to meet the needs of new production processes, featuring automation, cleanliness, and explosion-proof functions. The operating environment is a semiconductor material workshop, with a dust-free design and air cleanliness of Class 4 (equivalent to Class 7 of the national standard), meaning no more than 10,000 particles of 0.1 μm diameter per cubic meter. At the same time, since there are flammable and explosive gases in the workshop, the explosion-proof grade of the crane is dIICT4.

Product Features:

- Clean and Dust-Free: Utilizing high-pressure anti-static spraying technology and sealed welding structure, the entire crane is designed to be dust-free and non-polluting. Dust particles and lubricant oil stains are automatically cleaned through permanent magnetic mechanisms, explosion-proof electric dust collectors, and mechanical oil pans. Provides an ultra-low-noise working environment.

- Safety and Explosion-Proof: On the basis of cleanliness and intelligence, explosion-proof functionality adds another highlight. All operations are performed under explosion-proof conditions, making crane operation safer and more reliable.

- Intelligent Operation: Equipped with fully automatic unmanned operation, anti-sway precise positioning, automatic hooking and unhooking, with positioning accuracy reaching below millimeter level.

- Unmanned Functions: Comes with automatic fault alarms, automatic fault cause detection, component lifespan preset alarms, and other user-friendly features.

Explosion-Proof Overhead Cranes Applications

Explosion-proof overhead cranes is especially suitable for the following environments:

- Petrochemical plants: Hazardous gas and vapor environments (Zone 1 & Zone 2)

- Pharmaceutical / Painting workshops: Organic solvents, painting, and dust environments

- Grain processing plants: Combustible dust environments (grain dust, sugar powder, wood chips)

- Wastewater treatment plants / Biogas stations: Areas with methane gas presence

- New energy / Battery factories: Lithium battery dust and electrolyte environments

FAQ

The difference between ExdIIBT4 and ExdIICT4?

The applicable gas group is different, the typical gas of BT4 is ethylene, the typical gas of CT4 is hydrogen and acetylene, the product of CT4 is higher than BT4, CT4 can cover the application environment of BT4, and BT4 can not be applied in the CT4 environment.

What explosion-proof environments are explosion-proof cranes suitable for?

Explosion-proof cranes are mainly divided into three categories:

1. Explosion-proof cranes for coal mines —— suitable for gas (methane) environments;

2. Class II gas explosion-proof cranes —— suitable for explosive gas environments other than coal mines (Zone 1, Zone 2);

3. Class III dust explosion-proof cranes —— suitable for explosive dust environments (Zone 21, Zone 22).

In addition, according to different temperature groups (T1~T6), explosion-proof cranes can be safely applied in various hazardous environments such as ethylene, hydrogen, acrylonitrile, coal dust, sugar dust, and grain dust.

What national and international standards do explosion-proof cranes comply with?

Our company's explosion-proof overhead cranes are strictly designed, manufactured, and accepted in accordance with the following standards:

1. GB/T 3811-2008 《Design rules for cranes》

2. GB/T 6067-2010 《Safety rules for lifting appliances》

3. GB/T 3836.1-2021 《Explosive atmospheres-Part 1: Equipment-General requirements》;

4. GB/T 3836.2-2021 《Explosive atmospheres-Part 2: Equipment protection by flameproof enclosures "d"》;

5. JB/T 10219-2011 《Explosion-proof cranes with electric hoist》

6. JB/T 5897-2014 《Explosion-proof overhead traveling cranes》

All products are tested and certified by the National Center for Supervision and Inspection of Explosion-Proof Electrical Product Quality, ensuring compliance with ATEX and IECEx international explosion-proof standards.

Get in Touch

- Free and fast quote for the product.

- Provide you our product catalog.

- Your local crane projects from our company.

- Become our agent and earn commission.

- Any questions, contact us.

.png?w=200&h=134)