- EQUIPMENT

-

special cranes

-

Garbage Grab Crane

-

Foundry Overhead Crane

-

Explosion-proof Overhead Crane

-

Tongs Overhead Crane

-

Overhead Crane with Carrier-beam

-

Electromagnetic Overhead Cranes

-

Diesel Hydraulic Straddle Carrier: Flexible Operation and Affordable Solution for Container Handling

-

Upper Spillway Gate Gantry Crane: Reliable Solution for Dam Gate Hoisting and Hydropower Station Operations

-

Harbour Portal Crane: Powerful and Intelligent Solutions for Efficient Port Handling

-

Coke Pot Crane for CDQ: Exceptional Heavy-Duty Red-Hot Coke Handling

-

Emergency Rescue Specialized Crane for Water-Rescue Simulation: Engineered for Lifesaving Training

-

Intelligent Grab Bucket Overhead Crane: Powerful, Precise and Unmanned Bulk Material Handling Solution

-

Custom Multi-Point Suspension Overhead Crane for Large-Span and Load-Sensitive Industrial Buildings

-

Electrolytic Copper Cranes: Specialized in Efficient Cathode Plate Tank Loading and Transfer

-

Nuclear Polar Cranes: Multi-Function Lifting Machinery For Nuclear Power Plants

-

-

Industry Crane

-

Industry Crane

-

Tundish Cranes

-

Slab Cranes

-

Scrap Cranes

-

Billet Cranes

-

Coil,Bar and Plate Handling Cranes

-

Cement And Precast Crane

-

Power Station Crane

-

Ladle Cranes

-

Paper Industry Cranes

-

Waste to Energy Cranes and Biomass Cranes

-

Tailored Overhead Cranes for Aerospace: High Precision, Efficience, Safety and Reliability

-

Anode Baking Multifunctional Cranes: Versatile, High-Temp Resistant & Smart-Controlled Must-Have for Electrolytic Aluminum Industry

-

Multifunctional Crane For Electrolytic Aluminum: Fulfills All Aluminum Electrolysis Processes, Boosts Plant Efficiency

-

Warehouse Stacker Crane for AS/RS: High-Efficiency, Reliable, Fully Automated Storage

-

Slab Handling Overhead Crane: Metallurgical-Grade Crane for Continuous Casting and Slab Yards

-

Anode Carbon Block Stacking Cranes: 6-Layer Stacking, A Lifting Solution for Carbon Plants’ Efficient Transfer

-

Quenching Crane for Heat Treatment: Process-Oriented Overhead Crane Solution

-

Safe & Stable Scrap Charging Overhead Crane for Metallurgical Feeding Operations

-

Forging Overhead Crane: Reliable Lifting Equipment for Heavy-Duty Forging Workshops

-

Mold Handling Crane for AAC Production Line: Reliable Engineered Fixed-Position Lifting Solution

-

-

Hoist & Winch Trolley

-

Casting Electric Wire Rope Hoist

-

European Model Electric Hoist

-

Explosion-proof Electric Hoist

-

Low-headroom Electric Hoist

-

Electric Chain Hoist

-

2 Types Explosion-Proof Electric Chain Hoists for Hazardous Zones: Gas & Dust Protection

-

2 Types Explosion-Proof Electric Wire Rope Hoists for Industrial Safety: Reliable Gas & Dust-Proof Solutions

-

Manual Hoists for Precision Lifting: Explore 3 Proven Types for Power-Free Operation

-

Air Pneumatic Hoists: 4 Specialized Designs for Precision, Safety, and Harsh Environments

-

HC Type Electric Hoist: Heavy-duty Wire Rope Hoist for Factory Heavy Lifting

-

-

CRANE Spreader

-

Crane Electromagnetic Lifting Magnets

-

Lifting Electromagnet for Turning and Side Hung

-

Lifting Electromagnet for Thick Plate

-

Specialized Electromagnet for Lifting Steel Plates

-

Lifting Electromagnets for Lifting Steel Plates

-

Lifting Electromagnet for Heavy Rail and Profiled Steel

-

Lifting Electromagnet for High Speed Wier(Coiled Bar)

-

Lifting Electromagnet for Rebar and Steel Pipe

-

Lifting Electromagnet for Bundled Rebar and Profiled Steel

-

Lifting Electromagnet for Billet, Girder Billet and Slab

-

Lifting Electromagnet for Steel Scraps

-

- Crane Spreader

- Crane Hook

- Crane Lifting Tongs and Clamps

-

Crane Electromagnetic Lifting Magnets

- CRANE PARTS

- Transfer Cart

The Ultimate Guide to 5 Ton Overhead Crane: Types, Pricing & Real-World Applications

Table of Contents

In modern industrial production and material handling, the 5 ton overhead crane is one of the most widely used medium-duty lifting equipment, serving industries such as machinery manufacturing, warehousing and logistics, metal processing, mining, and papermaking. Its advantages include moderate lifting capacity, flexible configuration options, and reliable, mature structural design, making it the preferred choice for small to medium-tonnage lifting scenarios.

Depending on the structure of the facility, lifting clearance, frequency of use, and control requirements, 5 ton overhead cranes are available in various types: from the structurally simple LD single girder crane to compact low headroom and underslung designs, to high-performance FEM European-standard cranes and double girder cranes, catering to diverse industry needs and operating conditions.

This article delves into the various types of 5 ton overhead cranes, from single to double girder designs, analyzes the factors affecting their pricing, and showcases how to select the most suitable equipment through parameter comparisons and real-world case studies from Kuangshan Crane. Whether you are an engineer, procurement manager, or facility manager, this guide provides comprehensive decision-making support to help you choose the ideal industrial lifting solution.

Types of 5 Ton Overhead Crane

Below are the common types of 5 ton overhead cranes, covering single and double girder designs to meet diverse industrial needs:

LD Single Girder Overhead Crane

- Description: An economical single girder crane equipped with an electric hoist, suitable for light to medium material handling.

- Features: Simple structure, low cost, and easy installation, ideal for standard workshops.

Low Headroom Single Girder Overhead Crane

- Description: Designed for low headroom workshops, with the hoist positioned on the side of the beam to increase lifting height.

- Features: Saves vertical space, reduces building height requirements, suitable for space-constrained environments.

Underslung Single Girder Overhead Crane

- Description: Suspended from the workshop's roof tracks, suitable for facilities without load-bearing columns but with load-bearing roofs.

- Features: Saves floor space, ideal for small factories or warehouses.

FEM Standard Single Girder Overhead Crane

- Description: Designed based on European FEM standards, equipped with a low headroom electric hoist, suitable for high-precision tasks.

- Features: Lightweight, high rigidity, energy-efficient, ideal for high-demand workshops.

Offset Trolley Single Girder Overhead Crane

- Description: The hoist trolley is offset to one side of the main beam, optimizing lifting height and space utilization.

- Features: Suitable for low headroom and specialized workshop layouts, with smooth operation.

- Description: Operates along a single rail, suitable for linear or curved material handling.

- Features: Compact structure, ideal for narrow spaces or specific production lines.

European Top Running Double Girder Overhead Crane With Wire Rope Hoist

- Description: Based on European standards, a double girder design equipped with a hoist or winch trolley.

- Features: Compact structure, high efficiency, variable frequency speed control, suitable for high-end industrial applications.

LH-type Double Girder Overhead Crane With Hoist Trolley

- Description: Double girder design with a hoist trolley, suitable for medium load handling.

- Features: Lightweight structure, lower height, suitable for factories, mines, and similar settings.

QD-type Double Girder Overhead Crane With Open Winch Trolley

- Description: Equipped with a winch trolley, suitable for heavy-duty and frequent operations.

- Features: High load capacity, strong stability, ideal for steel mills, mines, and other heavy industries.

Common Applications of 5 Ton Bridge Cranes

The 5 ton overhead crane plays a critical role in multiple industrial sectors due to its flexible structure, moderate capacity, and ease of operation, making it suitable for daily handling, precision assembly, and high-frequency lifting tasks. Below are its typical application industries:

- Manufacturing: Used for handling raw materials, semi-finished products, and components, supporting efficient operation of automated production lines, commonly found in automotive, appliance, and heavy equipment factories.

- Warehousing and Logistics: Enables precise stacking and retrieval of goods in confined or elevated spaces, improving space utilization and loading/unloading efficiency, suitable for medium-sized warehouses and distribution centers.

- Machinery Workshops: Used for clamping, assembling, and loading/unloading heavy workpieces, enhancing operational safety and production precision, often paired with CNC machining equipment.

- Construction and Steel Structures: Facilitates lifting of formwork, steel plates, and components in rebar processing areas, prefabrication plants, and construction sites, boosting construction efficiency.

- Petrochemical: Supports lifting, testing, and maintenance of large valves and piping equipment, often used in explosion-proof or corrosion-resistant environments.

- Papermaking and Printing: Handles high-frequency lifting tasks for paper rolls and mold changes, ideal for moving parent rolls or components under 5 tons.

- Energy and Power: Assists in assembling and lifting transformers, circuit breakers, and busbars, suitable for maintenance and operations in power plants and substations.

5 Ton Overhead Crane Price

Understanding the pricing of 5 ton overhead cranes is key to selecting the right equipment. Prices vary depending on the crane type, span, lifting height, operating environment, and customized features. To assist with budgeting, we've categorized pricing for standard and customized products, helping users evaluate options and choose the best solution. Whether it's an economical single girder crane or a heavy-duty double girder design, clear pricing information and influencing factors will support your procurement decisions.

Standardized 5 Ton Overhead Crane Price Table

| Products | Span/m | Lifting Height/m | Working Duty | Price/USD |

|---|---|---|---|---|

| 5 Ton LD single girder overhead crane | 7.5-37.5 | 6-30 | A3-A5 | $2,439-16,214 |

| 5 Ton Low Headroom Single Girder Overhead Crane | 7.5-21.5 | 6-30 | A3 | $2,561-17,025 |

| 5 Ton Underslung Single Girder Overhead Crane | 3-16 | 6-18 | A3-A5 | $2,439-16,214 |

| 5 Ton FEM Single Girder Overhead Crane | 9.5-24 | 6-18 | A5 | $5,900-11,000 |

| 5 Ton Offset Trolley Single Girder Overhead Crane | 7.5-22.5 | 6-12 | A3 | $3,903-29,185 |

| 5 Ton Monorail Crane | Custom | 6-30 | M3 | $600-1,720 |

| 5 Ton LH-type Double Girder Overhead Crane With Hoist Trolley | 10.5-31.5 | 6-18 | A3-A4 | $12,195-81,070 |

| 5 Ton QD-type Double Girder Overhead Crane With Winch Trolley | 10.5-31.5 | 16 | A5-A6 | $12,195-81,070 |

| 5 Ton European Top Running Double Girder Overhead Crane With Wire Rope Hoist | 10.5-31.5 | 22 | A5 | $29,268-70,845 |

Note: Prices given in the table are for general reference only, actual prices may vary depending on the specific customisation or additional features required for the project.

Customized 5 Ton Eot Crane Price Examples

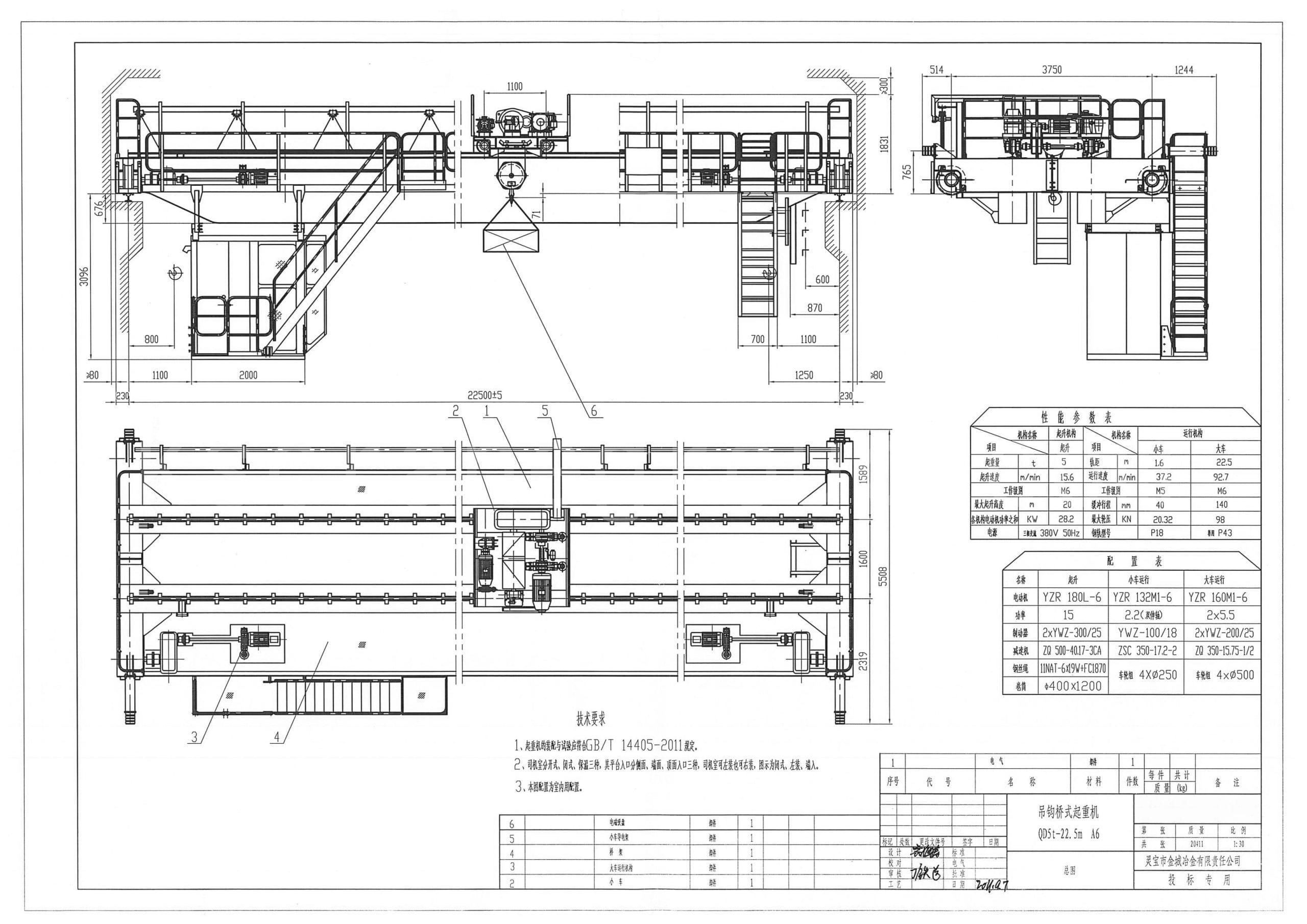

Product Parameters

- Type: Electromagnetic overhead cranes

- Capacity: 5 ton

- Span: 22.5 m

- Lifting height: 20 m

- Lifting speed: 15.6 m/min

- Traveling speed: 92.7 m/min (crane), 37.2 m/min (trolley)

- Working Duty: A6

- Control Method: Cabin control

- Price: $33,292

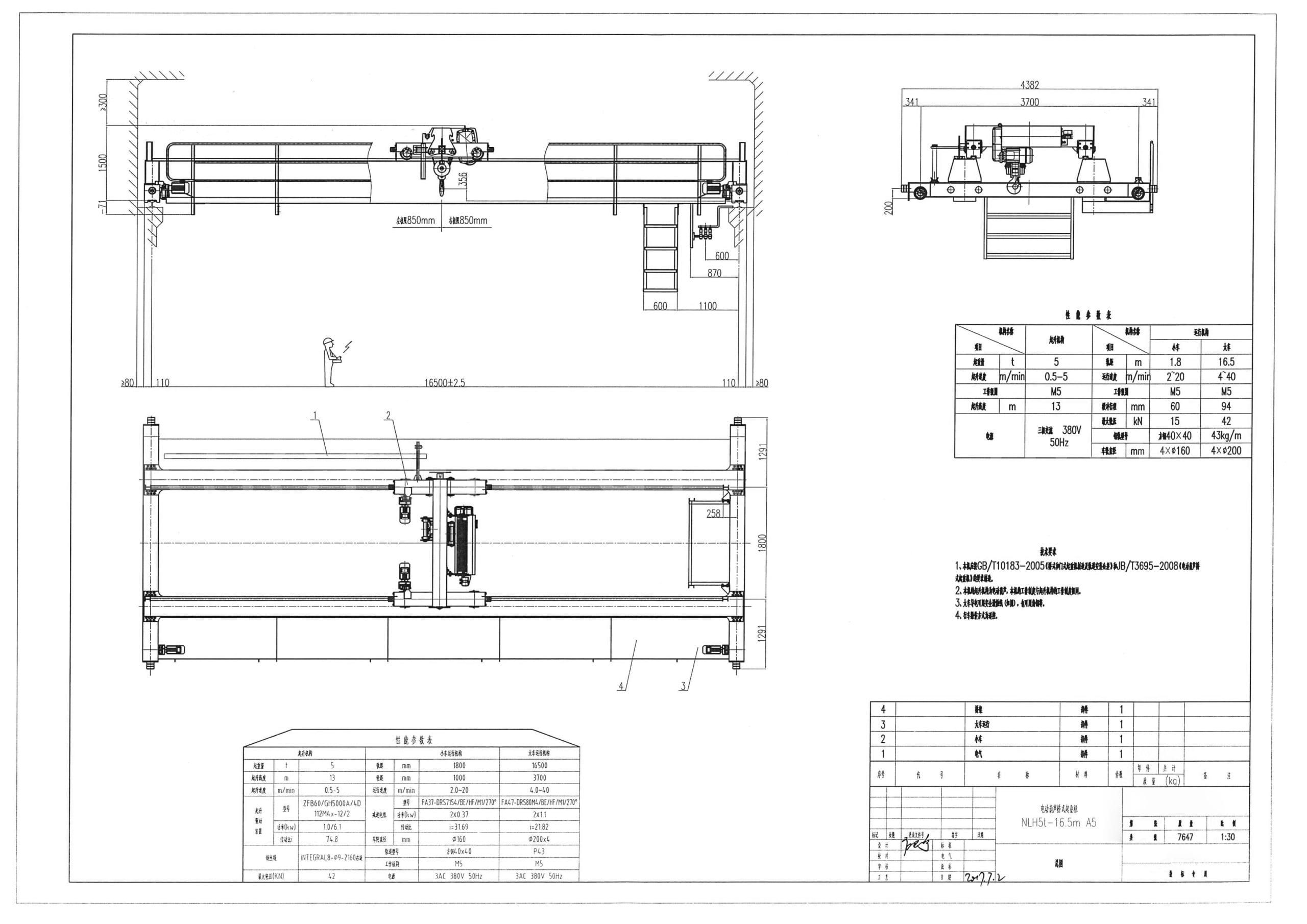

Product Parameters

- Type: European top running double girder overhead crane with wire rope hoist

- Capacity: 5 ton

- Span: 16.5m

- Lifting height: 13m

- Lifting speed: 0.5-5m/min

- Traveling speed: 4-40m/min (crane), 2-20m/min (trolley)

- Working Duty: A5

- Control Method: Remote control

- Price: $19,143

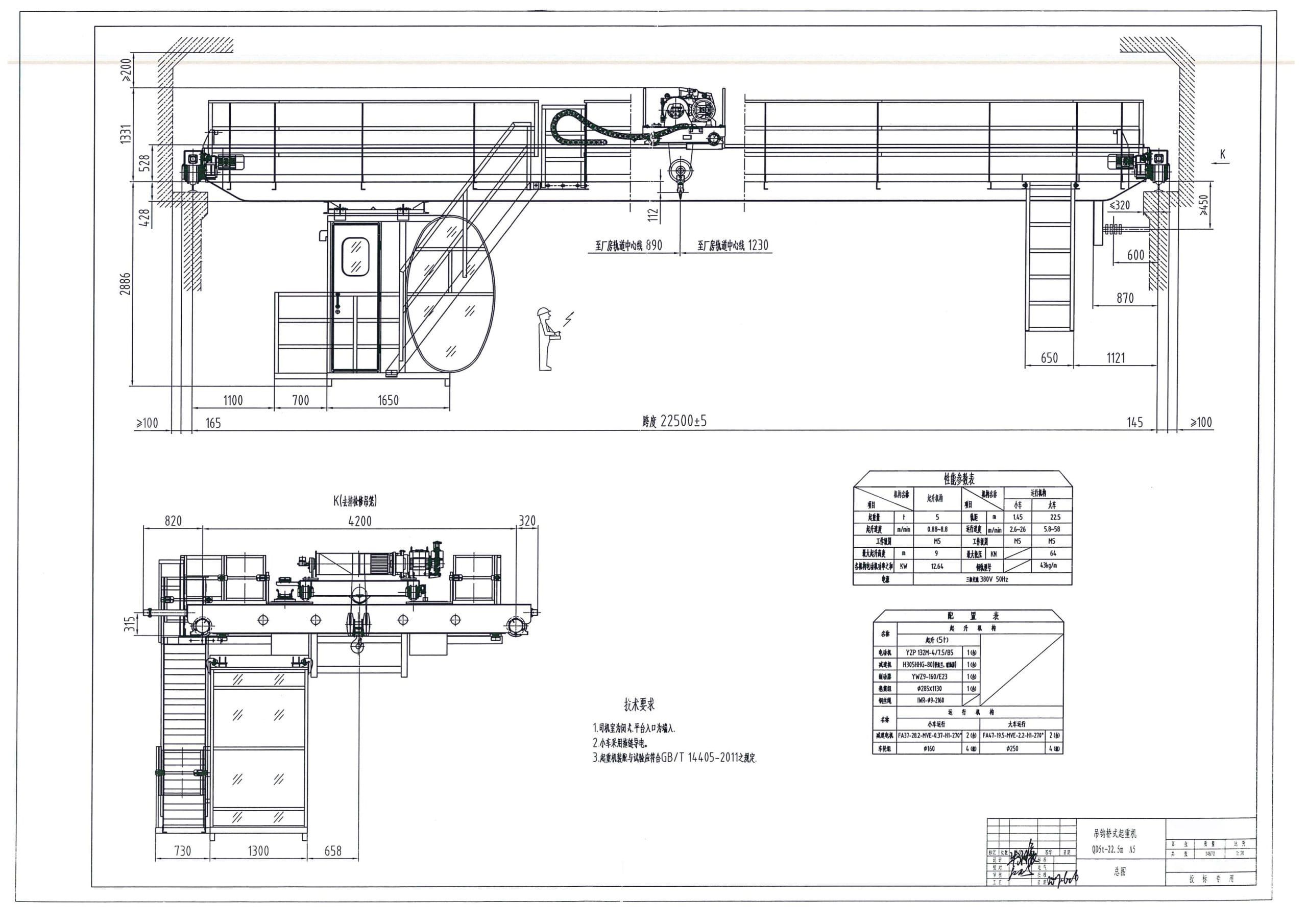

Product Parameters

- Type: European heavy duty double girder overhead crane with open winch hoist

- Capacity: 5 ton

- Span: 25.5m

- Lifting height: 9m

- Lifting speed: 0.88-8.8m/min

- Traveling speed: 5.8-58m/min (crane), 2.6-26m/min (trolley)

- Working Duty: A5

- Control Method: Cabin control

- Price: $23,800

Key Factors Affecting Pricing

- Lifting Capacity and Span: Larger spans or specialized designs significantly increase costs.

- Hoist Type: Standard CD/MD electric hoists are less expensive, while European-standard wire rope hoists or open winch hoists are pricier.

- Operating Environment: Requirements for explosion-proof, corrosion-resistant coatings, or high-temperature/humid conditions add extra costs.

- Control System Configuration: Features like variable frequency speed control, wireless remote control, or intelligent monitoring increase the overall price.

- Customization Advice: Provide manufacturers with clear specifications, such as lifting capacity, span, lifting height, working duty, and operating environment, to obtain accurate quotes.

Comparison of 5 Ton Overhead Crane Types

Based on varying facility structures, headroom requirements, usage frequency, and budget constraints, 5 ton overhead cranes can be categorized into several types. Below is a comparative analysis of key types to help you understand their applications and technical differences:

LD Single Girder Overhead Crane

LDC Low Headroom Single Girder Overhead Crane

- Standard Single Girder Overhead Crane (LD Type): Suitable for standard workshops, requiring sufficient vertical clearance to accommodate the main beam and electric hoist.

- Low Headroom Overhead Crane (LDC Type): By designing the hoist to operate offset or alongside the beam, it reduces overall equipment height, saving building height while maintaining the same lifting height, ideal for workshops with limited headroom or retrofit projects.

Standard Single Girder Overhead Crane (LD Type) vs. Underslung Single Girder Crane (LX Type)

LD Single Girder Overhead Crane

Underslung Single Girder Overhead Crane

- Standard Single Girder Overhead Crane (LD Type): Features a top-running structure, relying on ground columns or side beams for track support, suitable for standard facilities with load-bearing structures.

- Underslung Overhead Crane (LX Type): Tracks are installed under the roof or steel structure beams, with the trolley suspended below, maximizing facility height and ideal for workshops without columns or requiring cross-zone lifting.

Traditional Design Overhead Crane vs. FEM European-Standard Design Overhead Crane

LD Single Girder Overhead Crane

FEM Standard Single Girder Overhead Crane

- Traditional Single Girder Crane: Typically uses a separate motor and gearbox, resulting in a heavier structure and more frequent maintenance, suitable for routine handling tasks.

- FEM Standard Single Girder Crane: Employs a three-in-one drive system (motor, reducer, and brake integrated), offering a compact structure, smooth start/stop, smaller rear blind spots, and maintenance-free brake systems with high-frequency control units, significantly reducing noise and long-term maintenance costs, making it the preferred choice for users with higher performance demands.

Kuangshan Crane 5 Ton Overhead Crane Case Studies

5 Ton FEM Standard Single Girder Overhead Cranes Exported to Indonesia

At first, the customer wanted to produce the main beam themselves, and we would provide the remaining parts. After we gave them a quote, the customer’s engineer contacted us again, and we patiently answered all their questions. After a month of communication, the customer told me that their boss was very satisfied with our price and product, and they immediately purchased two complete machines.

Product Parameters:

- Crane capacity: 3T&5T

- Crane model: HD

- Span length: 9.15m

- Lifting height: 6m

- Work duty: A5

- Power source: 380V/50Hz/3Ph

- Control mode: Pendant + remote control

5-Ton FEM Standard Overhead Crane for Ethiopian Market: Tailored Solution for 27m Span

This is a long-term trusted Ethiopian customer who introduced us to a new customer. Our company successfully delivered an HD-type European single-girder bridge crane with a lifting capacity of 5 tonnes to this new customer.

During initial communications, the client expressed concerns about the transportation of the main beam with an ultra-long span of 27.76 metres. To address this challenge, our engineering team designed an efficient and feasible solution: dividing the main beam into three sections (each 11.8 metres long) for segmented transportation, and assembling them at the installation site using high-strength bolts and flange plates.

To ensure the structural strength at the joints, our company conducted multiple mechanical tests and on-site connection inspections to verify that the load-bearing performance of the assembled sections matches that of the entire main beam, fully meeting the lifting strength and safety requirements. Currently, the crane is being installed and commissioned by our professional team in collaboration with the customer, and it is expected to provide the customer with efficient and stable material handling support.

Product Parameters:

- Capacity: 5 tons

- Span: 27.76m

- Lifting height: 10.5m

- Lifting speed: 0.8/5m/min (slow/fast speed)

- Cross traveling speed: 2-20m/min (VFD speed)

- Long traveling speed: 3-30m/min (VFD speed)

- Main electrical components: Schneider

- Inverter for cross travel and long travel: Schneider

- Motors: Top brand from China

- Crane work duty: FEM 2m

- Control method: Pendant control

- Power supply: 380V 50HZ 3PH

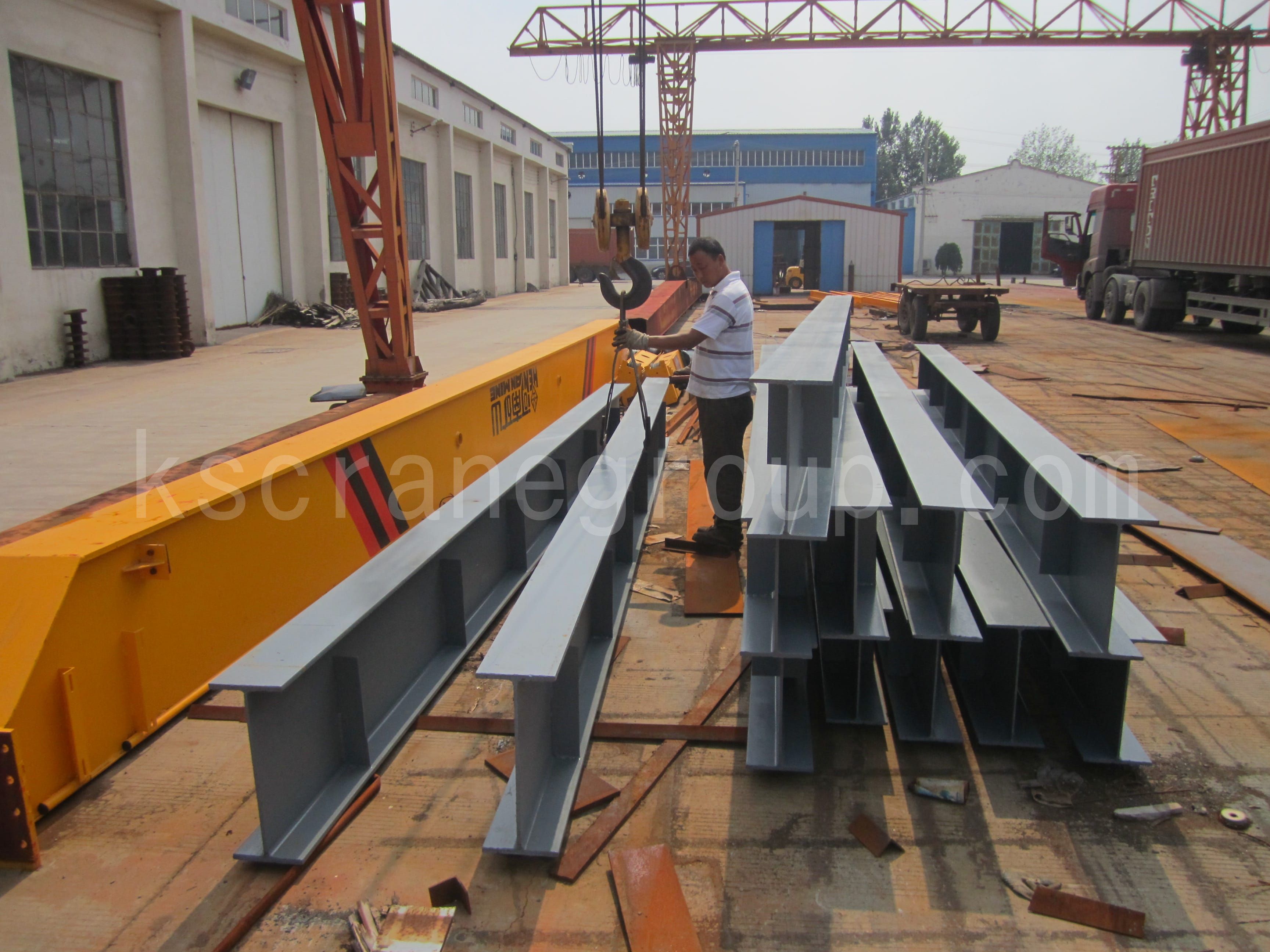

5 ton Double Girder Overhead Cranes Exported to Saudi Arabia

One of our long-term customers in Saudi Arabia expressed satisfaction with our products and services. They have once again purchased our double-girder bridge cranes, column-mounted jib cranes, and electric hoists. Our customers praised the exceptional quality of the equipment and the outstanding service provided by our team. We are proud to support their operations.

Product Parameters:

- Capacity: 5 ton

- Span: 16.98m

- Lift height: 7m

- Motors: ABM/SEW

5 ton Low Headroom Single Girder Overhead Crane Exported to Philippines

The Philippine customer plans to use cranes for steel plate lifting operations in a steel structure workshop. Due to the customer’s specific requirements for lifting height, but with overall height restrictions in the workshop, we selected a low-headroom single-girder bridge crane for them and matched it with a low-headroom electric hoist, effectively increasing the lifting height within the limited space and fully meeting the operational requirements. The customer placed a single order for three 5-ton low-headroom single-girder bridge cranes.

Henan Kuangshan Crane's 5 Ton Unmanned Intelligent Grab Bucket Overhead Crane

Autonomous intelligent grab cranes are indispensable mechanical equipment in the modern material handling industry. In response to special working environments such as radiation, high temperatures, dust, and strong corrosion, our company has developed and manufactured a 5-ton autonomous grab crane that integrates advanced intelligent technology.

Conclusion

As a cornerstone of modern industrial production, the 5 ton overhead crane, with its moderate lifting capacity, flexible configuration, and reliable structure, is a vital asset in industries such as machinery manufacturing, warehousing, metal processing, mining, and papermaking. From the cost-effective LD single girder crane to the high-performance FEM European-standard crane and the heavy-duty QD-type double girder crane, a variety of types cater to diverse facility structures and operating conditions.

This article provides a detailed exploration of crane types, pricing analysis, parameter comparisons, and real-world mining case studies from Kuangshan Crane, demonstrating how to select the most suitable crane based on span, lifting height, operating environment, and control requirements. Whether it's a low headroom design for space optimization or an explosion-proof double girder crane for harsh environments, these solutions deliver efficient and safe material handling.

Kuangshan Crane, a top 10 global crane manufacturer, offers extensive project experience and an expert team. Share your specific needs (e.g., span, lifting height, and work duty) to receive customized quotes and professional guidance, empowering your industrial operations to reach new heights of efficiency!

Do you like what we do?Share it

.png?w=200&h=134)