- EQUIPMENT

-

special cranes

-

Garbage Grab Crane

-

Foundry Overhead Crane

-

Explosion-proof Overhead Crane

-

Tongs Overhead Crane

-

Overhead Crane with Carrier-beam

-

Electromagnetic Overhead Cranes

-

Diesel Hydraulic Straddle Carrier: Flexible Operation and Affordable Solution for Container Handling

-

Upper Spillway Gate Gantry Crane: Reliable Solution for Dam Gate Hoisting and Hydropower Station Operations

-

Harbour Portal Crane: Powerful and Intelligent Solutions for Efficient Port Handling

-

Coke Pot Crane for CDQ: Exceptional Heavy-Duty Red-Hot Coke Handling

-

Emergency Rescue Specialized Crane for Water-Rescue Simulation: Engineered for Lifesaving Training

-

Intelligent Grab Bucket Overhead Crane: Powerful, Precise and Unmanned Bulk Material Handling Solution

-

Custom Multi-Point Suspension Overhead Crane for Large-Span and Load-Sensitive Industrial Buildings

-

Electrolytic Copper Cranes: Specialized in Efficient Cathode Plate Tank Loading and Transfer

-

Nuclear Polar Cranes: Multi-Function Lifting Machinery For Nuclear Power Plants

-

-

Industry Crane

-

Industry Crane

-

Tundish Cranes

-

Slab Cranes

-

Scrap Cranes

-

Billet Cranes

-

Coil,Bar and Plate Handling Cranes

-

Cement And Precast Crane

-

Power Station Crane

-

Ladle Cranes

-

Paper Industry Cranes

-

Waste to Energy Cranes and Biomass Cranes

-

Tailored Overhead Cranes for Aerospace: High Precision, Efficience, Safety and Reliability

-

Anode Baking Multifunctional Cranes: Versatile, High-Temp Resistant & Smart-Controlled Must-Have for Electrolytic Aluminum Industry

-

Multifunctional Crane For Electrolytic Aluminum: Fulfills All Aluminum Electrolysis Processes, Boosts Plant Efficiency

-

Warehouse Stacker Crane for AS/RS: High-Efficiency, Reliable, Fully Automated Storage

-

Slab Handling Overhead Crane: Metallurgical-Grade Crane for Continuous Casting and Slab Yards

-

Anode Carbon Block Stacking Cranes: 6-Layer Stacking, A Lifting Solution for Carbon Plants’ Efficient Transfer

-

Quenching Crane for Heat Treatment: Process-Oriented Overhead Crane Solution

-

Safe & Stable Scrap Charging Overhead Crane for Metallurgical Feeding Operations

-

Forging Overhead Crane: Reliable Lifting Equipment for Heavy-Duty Forging Workshops

-

Mold Handling Crane for AAC Production Line: Reliable Engineered Fixed-Position Lifting Solution

-

Pickling Overhead Cranes: For Acid Mist Environments in Non-ferrous Metal Smelting

-

-

Hoist & Winch Trolley

-

Casting Electric Wire Rope Hoist

-

European Model Electric Hoist

-

Explosion-proof Electric Hoist

-

Low-headroom Electric Hoist

-

Electric Chain Hoist

-

2 Types Explosion-Proof Electric Chain Hoists for Hazardous Zones: Gas & Dust Protection

-

2 Types Explosion-Proof Electric Wire Rope Hoists for Industrial Safety: Reliable Gas & Dust-Proof Solutions

-

Manual Hoists for Precision Lifting: Explore 3 Proven Types for Power-Free Operation

-

Air Pneumatic Hoists: 4 Specialized Designs for Precision, Safety, and Harsh Environments

-

HC Type Electric Hoist: Heavy-duty Wire Rope Hoist for Factory Heavy Lifting

-

-

CRANE Spreader

-

Crane Electromagnetic Lifting Magnets

-

Lifting Electromagnet for Turning and Side Hung

-

Lifting Electromagnet for Thick Plate

-

Specialized Electromagnet for Lifting Steel Plates

-

Lifting Electromagnets for Lifting Steel Plates

-

Lifting Electromagnet for Heavy Rail and Profiled Steel

-

Lifting Electromagnet for High Speed Wier(Coiled Bar)

-

Lifting Electromagnet for Rebar and Steel Pipe

-

Lifting Electromagnet for Bundled Rebar and Profiled Steel

-

Lifting Electromagnet for Billet, Girder Billet and Slab

-

Lifting Electromagnet for Steel Scraps

-

- Crane Spreader

- Crane Hook

- Crane Lifting Tongs and Clamps

-

Crane Electromagnetic Lifting Magnets

- CRANE PARTS

- Transfer Cart

Ceiling Mounted Bridge Cranes: Lightweight and Efficient Workstation Handling Assistants

Product Description

Ceiling Mounted Bridge Cranes, also known as a Ceiling Mounted Bridge Workstation Crane, is a light lifting machine that operates via a rail system mounted on a ceiling or overhead structure. This crane system consists of a load-bearing structure, main girder, end girder, electric hoist, and electric sports car, which can be moved along a specified path, and is mainly used in industrial plants with material accumulation, large manufacturing or maintenance workshops and warehouses, and other places that need to maximize the maintenance of floor workspace, and workstation production lines. It is characterized by the use of the top of the building’s carrying capacity to achieve the erection of lifting machinery, does not take up space on the ground, especially suitable for low headroom plant as well as space constraints, the need to make full use of the ground for other operations in the environment.

Product Parameters:

- Lifting Height: determined by the height of the plant

- Lifting Capacity: determined by the load bearing capacity of the top of the space, 80 kg~2 ton

- Span: 3~10m, retractable beams can be added to realize operations beyond the range of the lifting point, and the coverage can be extended to 1.5 times of the original

- Working Duty: A4

- If there are special requirements, non-standard design and manufacture are available.

Product Advantages:

- Flexible coverage of multiple stations, matching the assembly line beat

- Adopt modular ceiling-type structure, can be laid out along the production line, to achieve the material lifting and loading of multiple assembly stations,

- Suitable for multi-species, small batch flexible manufacturing needs

- Release the ground space, the ground can be realized without obstacles to peers, to ensure that the other transport equipment is free to pass through without hindering the other work processes

- Ceiling-mounted overhead travelling crane is light in deadweight and low in resistance, which can be realized Single person operation

- Modular design, can be quickly adapted to the new process, good adaptability, high transformation efficiency

5 Types of Ceiling Mounted Bridge Cranes

According to the different lifting capacity, if the lifting capacity is larger, such as more than 2 tons, choose the double girder form than single girder operation is more stable and better performance

In more complex working conditions, such as the intersection of multiple equipment or extremely limited space in the area, you can choose to increase the telescopic beam to cover the area where the ordinary lifting machinery can not enter the area of the crane for lifting

If the requirements for positioning accuracy is not strict, it is recommended to use flexible connection ceiling-mounted overhead travelling crane, the cost is lower, the structure is more lightweight, and if there is a high requirement for precise positioning, it is recommended to choose rigid connection method to achieve accurate alignment. The cost is lower and the structure is lighter. If the requirement of positioning accuracy is high, it is recommended to choose the ceiling-mounted overhead travelling crane with rigid connection to realize accurate positioning.

Flexible Single Girder Ceiling Mounted Bridge Crane

Lifting capacity: 80 kg- 1 ton

The use of a single main beam and monorail running trolley form, suspended from the ceiling requires ground space, low cost, lightweight structure, suitable for small tonnage, and low-frequency lifting

Flexible Double Girder Ceiling Mounted Bridge Crane

Lifting capacity: 125kg-2ton

The two main girders are connected in a flexible way to span between the rails, compared with the flexible single girder, it can be more stable to lift the materials, with larger lifting capacity and better stability, and the electric hoist trolley moves between the two main girders to lift the goods.

Telescopic Beam Suspension Workstation Crane

Lifting capacity: 80 kg- 2 ton

Telescopic beams hanging below the main beam can expand the coverage area to a certain extent, suitable for short trips and workstation supplemental lifting operations

Rigid Connection Single Girder Ceiling Mounted Bridge Crane

Lifting capacity: 80kg-2ton

The rigid beam is relatively thick and has no elastic deformation. The electric hoist trolley runs smoothly along the track under the main beam and can accurately lift heavier goods.

Rigid Connection Double Girder Ceiling Mounted Bridge Crane

Lifting capacity: 125kg-3ton

The two main girders are rigidly connected to span between the rails, which provides a heavier load, high positioning accuracy, anti-swinging, anti-diagonal pulling phenomenon, and prevents the main girder from jamming while moving easily, supporting customization of medium-length travels and larger spans, and wider coverage areas.

Ceiling Mounted Bridge Cranes Component

Running track

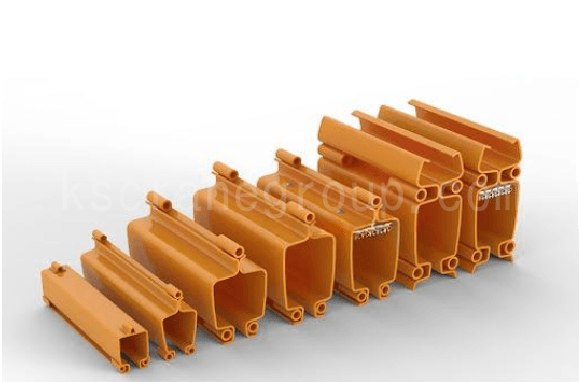

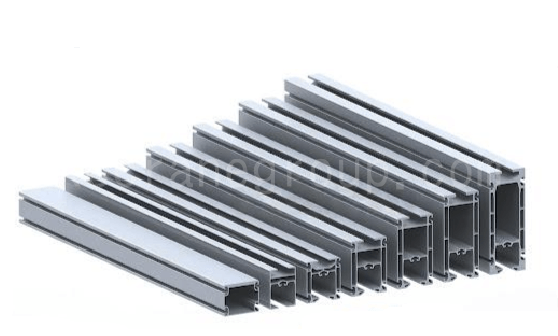

Cold rolled carbon steel, aluminum alloy, etc. (Special materials need to be non-standard customized)

- If you are sensitive to the cost, the use of the environment is more common, and the lifting capacity is large, it is recommended that the use of cold rolled carbon steel

- If you need to be lightweight operation, frequent lifting, manual pushing and pulling, or in a clean environment, it is recommended to use aluminum alloy rail system

Cold Rolled Carbon Steel Track

Aluminum Track

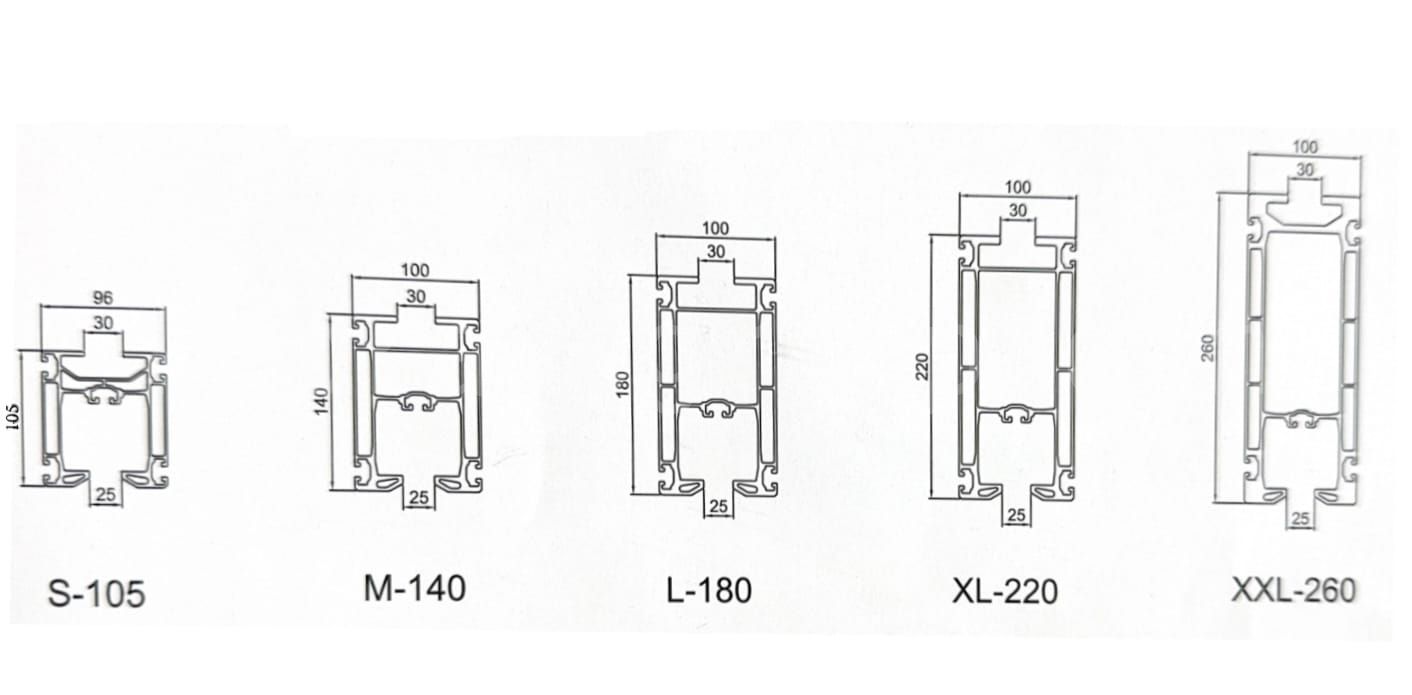

Aluminum Track Technical Specifications

| Model Number | Height/mm | Width/mm | Rated Load/kg | Weight/kg/m |

| S-105 | 105 | 96 | 250 | 5.4 |

| M-140 | 140 | 100 | 500 | 7.4 |

| L-180 | 180 | 100 | 750 | 8.5 |

| XL-220 | 220 | 100 | 1200 | 10 |

| XXL-260 | 260 | 100 | 2000 | 17.5 |

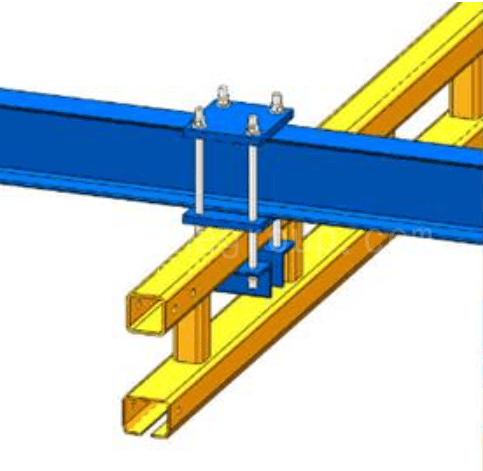

Track system structure connection mode: Flexible link track system/Rigid link track system

- Flexible system is fixed on the roof structure by suspension, the rail has a certain swing type, suitable for light load, operation flexibility requires high occasions.

- The rigid system is generally connected by bolts. The track has strong rigidity, small swing, and high running accuracy. It is suitable for large loads or high-frequency and high-precision occasions.

Ceiling mounted bridge crane flexible track system

Ceiling mounted bridge crane rigid track system

Hoisting Equipment

Ceiling bridge crane systems are often used with various types of lightweight lifting devices to meet different work stations, processes and load requirements. Common lifting devices include electric chain hoists, intelligent hoists (servo-electric lifting system) and so on. According to specific application scenarios, users can choose intelligent lifting devices with infrared sensor control or automatic homing function to realize high-frequency, safe and low-noise handling of materials such as boxes, molds, workpieces and equipment components. Reasonable selection of lifting devices not only enhances the overall system efficiency, but also enhances the operator’s comfort and work accuracy.

Electric chain hoist

- Electric chain hoists – lightweight and space-saving, suitable for workshops with limited headroom

- Perfect safety protection, can be equipped with upper and lower limits, overload protection, power failure brake, etc.

- Electric chain hoists are stable in operation, precise in positioning, smooth in lifting, and low in vibration.

- Convenient to operate, can be completed by a single person to lift and load.

Intelligent hoist

- Host: The host component of the intelligent auxiliary lifting equipment is mainly responsible for providing the equipment with accurate control, the power required for lifting and signal processing.

- Spiral cable: the role of the spiral cable is to transmit signals between the host and the handle, the transmission of signals, including the lifting direction, lifting speed, emergency stop signals and fault signals.

- The handle is the main interface between the operator and the lifting equipment. The user controls the lifting and lowering of the equipment through the handle, and at the same time obtains the corresponding information through the display.

Product Features:

- Greater responsiveness

- Easy load positioning

- High quality and low price

- Low equipment damage rate

- Low risk of accident

- Resistant to dust and moisture, more environmentally friendly

- Easy installation and operation

- Improve production efficiency

Intelligent hoist parameters

- Control mode: servo control (position control)

- Lifting medium: stainless steel wire rope

- Operating ambient temperature range: 5-55℃

- Operating ambient humidity range: 35%-90% non-condensing

- Power supply available for the tool: 24VDC, 0.5A

- Accuracy of weight display: ±1 rated lifting capacity

- Cooling mode: natural or forced air

- Noise: ≤80dB

| Maximum lifting weight (heavy and fixture) (KG) | 80 | 200 | 300 | 600 |

| Maximum lifting speed – manual mode (m/min) | 40 | 30 | 15 | 7.5 |

| Maximum lifting speed – suspension mode (m/min) | 36 | 27 | 13.5 | 6.75 |

| Maximum lifting height (m) | 3.5 | 3.5 | 3.5 | 3.5 |

| Rated power | 750W | 1500W | 2000W | 2000W |

| Maximum current (A) | 10 | 12 | 15 | 15 |

| Mains power (VAC) | single phase 220±10% | single phase 220±10% | three phase220V±10% | three phase220V±10% |

Ceiling Mounted Bridge Cranes Applications

As one of the most common and widely used general-purpose lifting equipments, ceiling-mounted overhead travelling crane has been widely used in all kinds of industrial production and material handling scenarios due to its simple structure, strong load carrying capacity and wide range of application. Whether it is machinery overhaul, injection molding, warehousing and logistics, parts assembly, ceiling-mounted overhead travelling crane can satisfy the lifting needs under different working conditions by virtue of its stable operation performance and good versatility.

Injection Molding Workshop

In the injection molding workshop, lifting machinery is mainly used for mold replacement, injection molding machine repair and maintenance, as well as large plastic parts handling operations. Since the production process involves the transportation of many kinds of raw materials, auxiliary materials and packaging materials, the selection of lifting equipment needs to take into account the lifting precision, plant space constraints, operational safety and production efficiency to ensure a smooth and efficient production process. The use of a ceiling mounted bridge crane can be a good solution to these problems because it occupies little space, has a large lifting height and covers a wide area. Similar scenarios are also applicable to CNC machining shops for transferring finished products and so on. The main advantages include:

- Saving floor space and improving space utilization: no need for floor support columns, maximizing the release of floor space for equipment arrangement and personnel access.

- Wide coverage and flexible scheduling: It can be designed to cover the entire injection molding area, realizing seamless handling of molds from the storage area to the injection molding machine, supporting multi-station operation and improving production efficiency.

- Adapt to the requirements of clean workshop: the environmental requirements of injection molding workshop are higher than those of ordinary workshop, especially the dust environment will affect the product appearance and performance requirements, and in the long run, it will affect the accuracy of the mold.

The use of this system significantly improves the efficiency of mold replacement and optimizes the production process in the workshop.

Large Equipment Overhaul Workshop

In the heavy truck service center for vehicle maintenance, involves many large heavy parts disassembly, replacement and maintenance, part of the components are large, heavy weight, installation location special, must use lifting equipment to assist in the operation, such as heavy trucks gearboxes and reducers. Large maintenance centers usually need a very large open space and above the use of all-steel structure, aircraft maintenance workshop hangars need to keep the ground open to park the aircraft, some of the aircraft need to be 100m * 100m or more column-free space, the top suspension design can effectively achieve 100% ground free, to ensure that the aircraft in and out of the maintenance equipment and layout flexibility. In addition, the precision parts that need to be operated for aircraft maintenance have high precision requirements, which usually require cranes equipped with frequency control and anti-sway systems.

- Ceiling-mounted design for maximum headroom and unobstructed floor space for smoother operations

- The floor is kept clean for other important tasks

- Track layouts can be customized to meet the complex structural steel beams on the roof, bypassing or staggering structural obstacles

Similar systems are also widely used in heavy truck service centers, railroad maintenance depots, wind power maintenance plants and other large-scale transportation equipment maintenance sites.

Assembly of parts for large manufacturing industries

Lifting, assembly and transfer of parts for automotive assembly plants, marine spare parts plants, construction machinery manufacturers, such as engines, chassis systems, control systems, etc., are usually in an assembly line arrangement or multiple assembly workstations. The use of ceiling-mounted overhead cranes can fulfill fast and precise parts installation within the load-bearing range of the ceiling. And telescopic beams can be designed as needed to meet the workplace under ventilation ducts, in corners, and between columns. The main advantages include:

- Flexible configuration: it can be matched with intelligent tools: such as automatic lifting platform and intelligent mechanical arm to meet more complex operational needs, combined with rotating lifting beams, etc., to realize precise alignment of engine, cab and other components installation

- Wide coverage: can cover multiple assembly tables to meet multiple work tasks at the same time

- Easy to expand and maintain: modular rail design, flexible deployment according to production line adjustment, easy to add, reorganize and relocate.

Ceiling Mounted Bridge Crane Export Case

3 Sets Ceiling Mounted Bridge Crane Exported To Australia

Background: The customer’s project is an Australian automotive parts manufacturer, the production process involves a large number of medium-sized molds, stamping parts and assembly equipment handling work. Due to the compact layout of equipment in the workshop, the ground can not be set up columns, the customer wants to adopt a lifting solution that does not need to take up floor space, easy to install and flexible in operation.

After a comprehensive comparison of equipment from several suppliers, the customer finally chose the ceiling suspension bridge crane system provided by our company. Key considerations included:

- Column-less structure, completely installed on the roof beams, which maximizes the release of the workshop floor;

- Light weight, low noise and low maintenance, ideal for long hours and high frequency operation;

- The modular rail design supports subsequent expansion and low equipment upgrade costs;

- In order to meet the high standard of electrical safety, the system is equipped with Schneider brand electrical control and loss-of-voltage protection unit, which further enhances the stability and safety of operation.

Basic parameters:

- Lifting capacity: 1 ton/2 tons

- Lifting height: 6m

- Span: 8m

- Operation mode: remote control operation

After the system was installed and put into use, the automotive parts manufacturer’s efficiency and output increased significantly, and reduced the safety risks of the process that would otherwise require manual operation, further promoting the realization of intelligent, flexible production layout of the workshop.

Conclusion

As modern industry continues to improve its requirements for space utilization, operational efficiency and equipment flexibility, ceiling mounted bridge crane, as a highly efficient and flexible lifting solution, is increasingly playing an important role in a variety of industries such as manufacturing, maintenance, logistics and construction. Whether it is an injection workshop where molds are frequently replaced, or a heavy truck maintenance center where a large area of the floor needs to be kept clear, or an assembly line with stringent requirements for high-precision positioning, ceiling mounted bridge cranes can provide reliable support, especially lightweight bridge cranes represented by modular system, which have become the preferred choice of more and more enterprises due to their advantages of easy installation, light weight and flexible combination.

As can be seen from the export cases, this type of crane has been widely served in the international market, bringing significant value to customers in terms of plant layout, safety management and subsequent expansion. In the future, with the development of industrial intelligence, ceiling mounted overhead cranes will continue to be optimized, helping more industries to achieve efficient and safe material handling and production operations.

Get in Touch

- Free and fast quote for the product.

- Provide you our product catalog.

- Your local crane projects from our company.

- Become our agent and earn commission.

- Any questions, contact us.

.png?w=200&h=134)