- EQUIPMENT

-

special cranes

-

Garbage Grab Crane

-

Foundry Overhead Crane

-

Explosion-proof Overhead Crane

-

Tongs Overhead Crane

-

Overhead Crane with Carrier-beam

-

Electromagnetic Overhead Cranes

-

Diesel Hydraulic Straddle Carrier: Flexible Operation and Affordable Solution for Container Handling

-

Upper Spillway Gate Gantry Crane: Reliable Solution for Dam Gate Hoisting and Hydropower Station Operations

-

Harbour Portal Crane: Powerful and Intelligent Solutions for Efficient Port Handling

-

Coke Pot Crane for CDQ: Exceptional Heavy-Duty Red-Hot Coke Handling

-

Emergency Rescue Specialized Crane for Water-Rescue Simulation: Engineered for Lifesaving Training

-

Intelligent Grab Bucket Overhead Crane: Powerful, Precise and Unmanned Bulk Material Handling Solution

-

Custom Multi-Point Suspension Overhead Crane for Large-Span and Load-Sensitive Industrial Buildings

-

Electrolytic Copper Cranes: Specialized in Efficient Cathode Plate Tank Loading and Transfer

-

Nuclear Polar Cranes: Multi-Function Lifting Machinery For Nuclear Power Plants

-

-

Industry Crane

-

Industry Crane

-

Tundish Cranes

-

Slab Cranes

-

Scrap Cranes

-

Billet Cranes

-

Coil,Bar and Plate Handling Cranes

-

Cement And Precast Crane

-

Power Station Crane

-

Ladle Cranes

-

Paper Industry Cranes

-

Waste to Energy Cranes and Biomass Cranes

-

Tailored Overhead Cranes for Aerospace: High Precision, Efficience, Safety and Reliability

-

Anode Baking Multifunctional Cranes: Versatile, High-Temp Resistant & Smart-Controlled Must-Have for Electrolytic Aluminum Industry

-

Multifunctional Crane For Electrolytic Aluminum: Fulfills All Aluminum Electrolysis Processes, Boosts Plant Efficiency

-

Warehouse Stacker Crane for AS/RS: High-Efficiency, Reliable, Fully Automated Storage

-

Slab Handling Overhead Crane: Metallurgical-Grade Crane for Continuous Casting and Slab Yards

-

Anode Carbon Block Stacking Cranes: 6-Layer Stacking, A Lifting Solution for Carbon Plants’ Efficient Transfer

-

Quenching Crane for Heat Treatment: Process-Oriented Overhead Crane Solution

-

Safe & Stable Scrap Charging Overhead Crane for Metallurgical Feeding Operations

-

Forging Overhead Crane: Reliable Lifting Equipment for Heavy-Duty Forging Workshops

-

Mold Handling Crane for AAC Production Line: Reliable Engineered Fixed-Position Lifting Solution

-

-

Hoist & Winch Trolley

-

Casting Electric Wire Rope Hoist

-

European Model Electric Hoist

-

Explosion-proof Electric Hoist

-

Low-headroom Electric Hoist

-

Electric Chain Hoist

-

2 Types Explosion-Proof Electric Chain Hoists for Hazardous Zones: Gas & Dust Protection

-

2 Types Explosion-Proof Electric Wire Rope Hoists for Industrial Safety: Reliable Gas & Dust-Proof Solutions

-

Manual Hoists for Precision Lifting: Explore 3 Proven Types for Power-Free Operation

-

Air Pneumatic Hoists: 4 Specialized Designs for Precision, Safety, and Harsh Environments

-

HC Type Electric Hoist: Heavy-duty Wire Rope Hoist for Factory Heavy Lifting

-

-

CRANE Spreader

-

Crane Electromagnetic Lifting Magnets

-

Lifting Electromagnet for Turning and Side Hung

-

Lifting Electromagnet for Thick Plate

-

Specialized Electromagnet for Lifting Steel Plates

-

Lifting Electromagnets for Lifting Steel Plates

-

Lifting Electromagnet for Heavy Rail and Profiled Steel

-

Lifting Electromagnet for High Speed Wier(Coiled Bar)

-

Lifting Electromagnet for Rebar and Steel Pipe

-

Lifting Electromagnet for Bundled Rebar and Profiled Steel

-

Lifting Electromagnet for Billet, Girder Billet and Slab

-

Lifting Electromagnet for Steel Scraps

-

- Crane Spreader

- Crane Hook

- Crane Lifting Tongs and Clamps

-

Crane Electromagnetic Lifting Magnets

- CRANE PARTS

- Transfer Cart

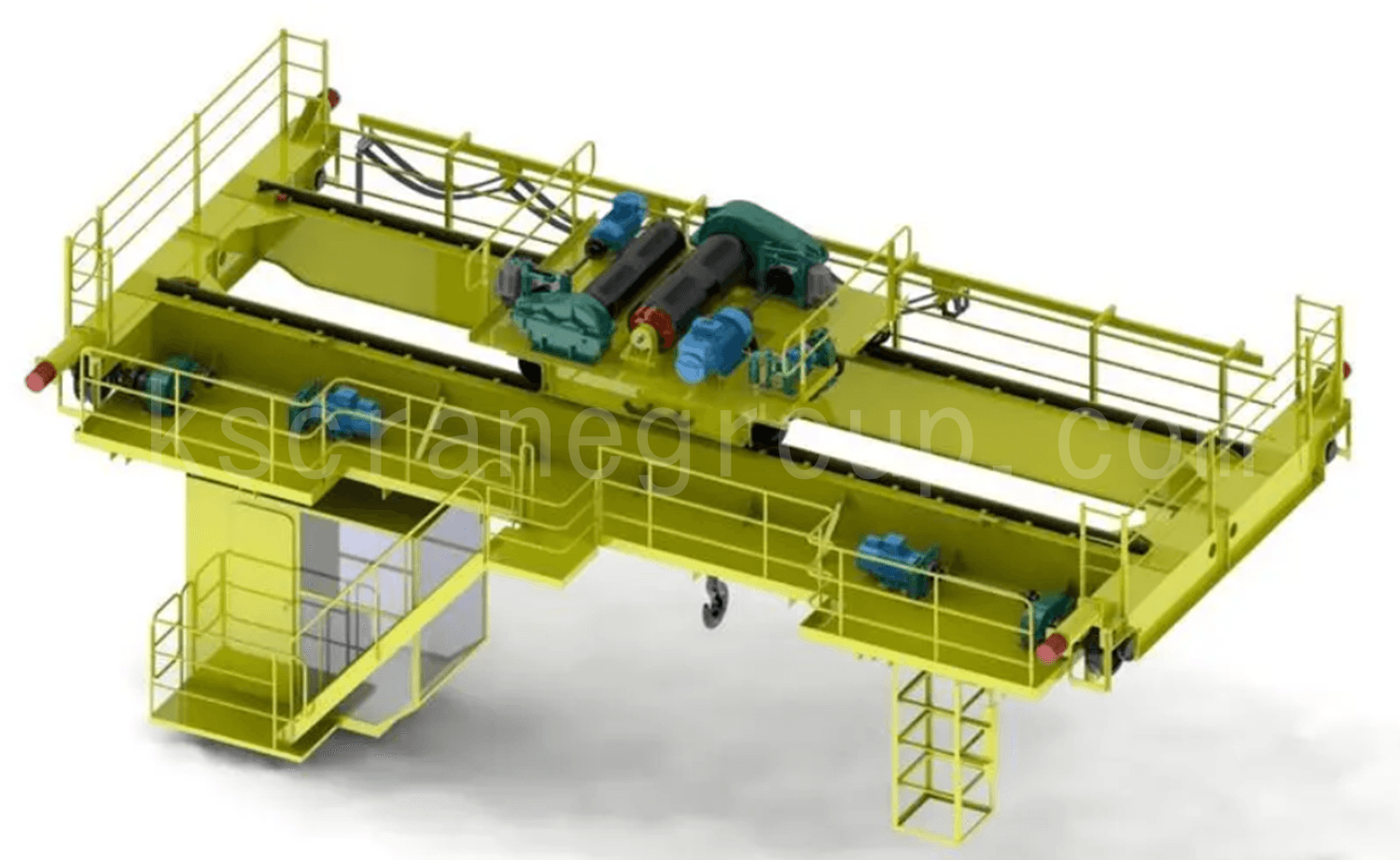

Double Girder Overhead Crane: Smart Design, Energy-Saving, and Built for Long-Term Success

The design, manufacturing, and inspection of this double girder overhead crane are carried out in accordance with national standards, with partial adoption of foreign standards such as FEM, DIN, and IEC. Compared with the conventional QD-type bridge crane, its self-weight is reduced by about 15–30%, and the wheel pressure is reduced by about 10–35%, which lowers the structural requirements of the plant and saves construction costs. The core components of the transmission mechanism, the reducers, all adopt hardened gear surfaces with high-precision gear pairs. Together with the use of steel drums, forged wheels, and frequency conversion speed control systems, this model of crane has become a new generation product that delivers both economic and social benefits. It is suitable for industries such as machinery manufacturing, assembly, petrochemicals, warehousing and logistics, power construction, papermaking, and railways.

- Lifting capacity: 5t~125t

- Span: 10.5m~31.5m

- Lifting height: 16m~26m

- Working group: A5

Double Girder Overhead Crane with Open Winch Features

- The main beam adopts an offset rail box-type structure and is connected to the end beams with high-strength bolts, making transportation convenient. Specialized processing equipment ensures the connection accuracy between the main and end beams, allowing the crane to operate smoothly.

- The hoisting trolley features an open-type compact winch structure.

- The long and cross travel mechanisms adopt the European three-in-one drive technology, equipped with hardened-surface reducers. The structure is compact, with low noise, no oil leakage, and long service life.

- Thanks to the use of the European compact trolley and high-strength materials, the overall dimensions of the crane are smaller, and the weight is lighter. Compared with traditional cranes, under the same lifting height conditions, the plant height can be reduced, effectively lowering construction costs.

- Modular design, with a short design cycle, high degree of universality, and improved utilization of parts.

- Compact structure, low headroom, small overall dimensions, wide working range, effectively improving production efficiency.

- Full frequency conversion control, stable operation without impact, slow speed under heavy load, fast speed under light load, energy saving and consumption reduction.

Double Girder Overhead Crane with Open Winch Specifications

Double Girder Overhead Crane with Open Winch Structure

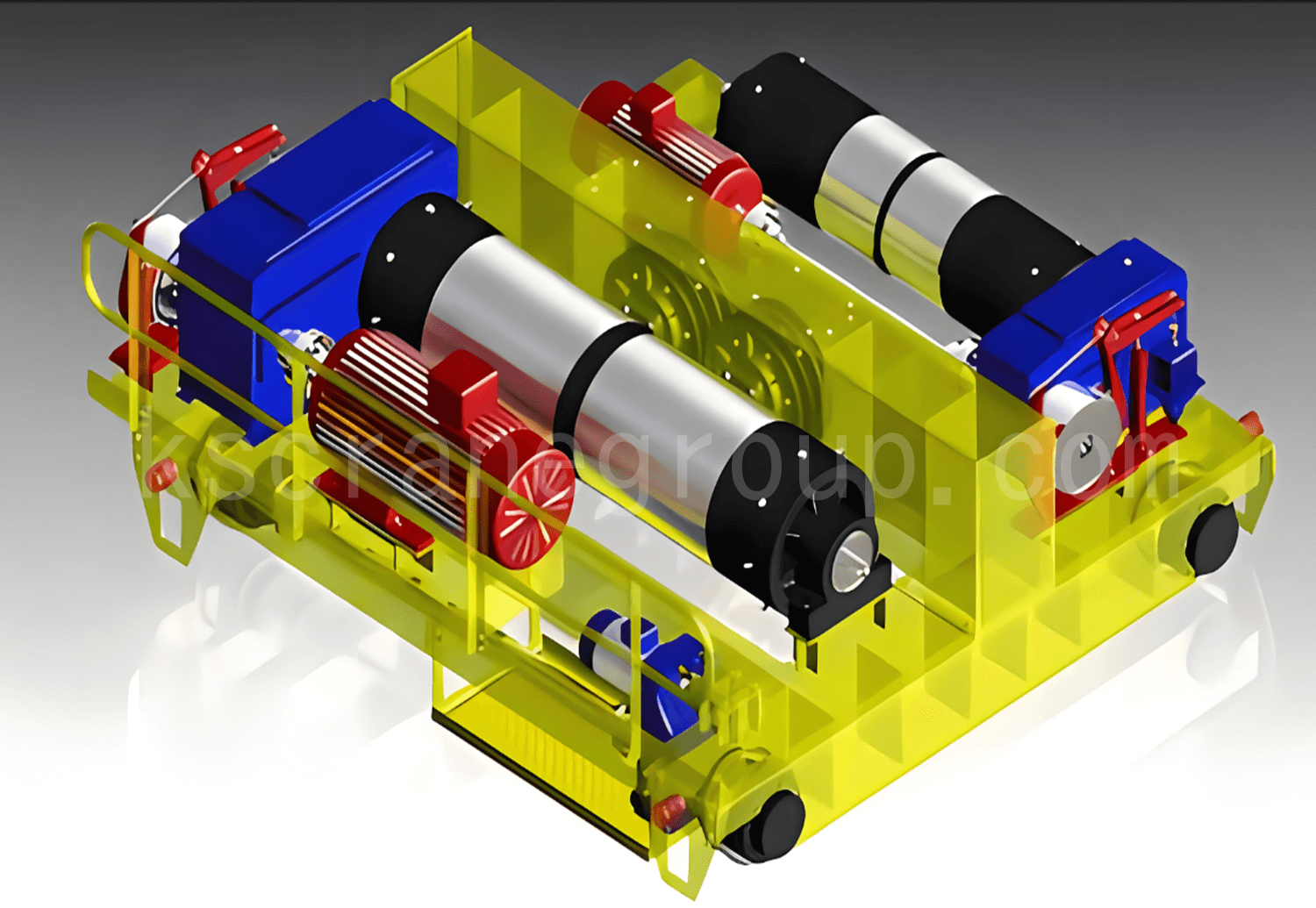

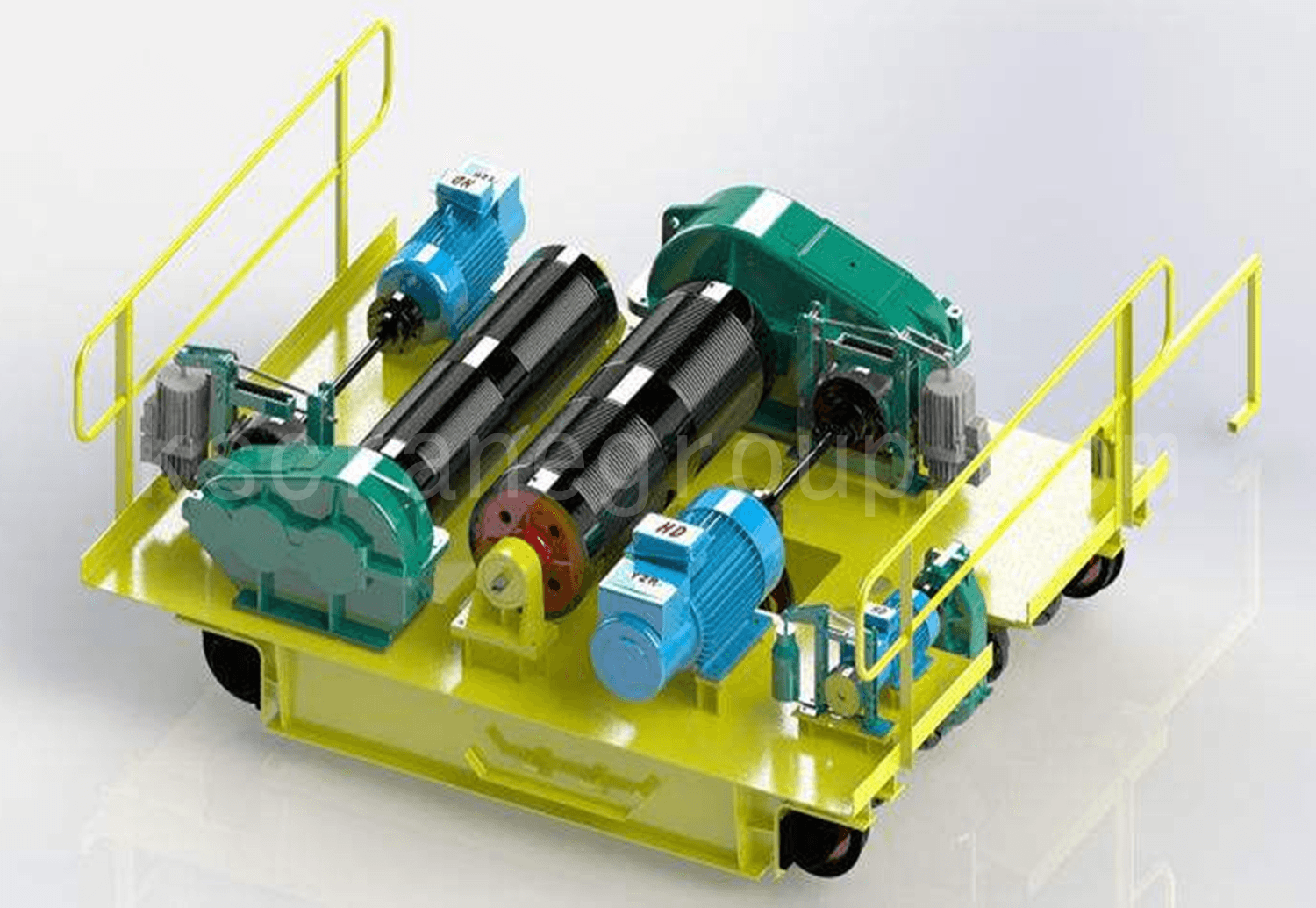

Double Girder Overhead Crane with Open Winch Hoist adopts an independent trolley structure with a lightweight design. The lifting load is directly applied to the running end beams on both sides of the trolley frame, resulting in clear force distribution. With a compact layout, it offers high transmission efficiency, low noise, and reduced overall height and self-weight of the crane.

Trolley Traveling Mechanism

- Compact three-in-one structure integrating motor, reducer, and brake. The motor has insulation class F, protection grade IP55, a duty cycle of 40%, thermal protection, and is equipped with an electromagnetic disc brake. The reducer has hardened gear surfaces and is ground or shaved, with no need to change the oil during its service life.

- Forged wheels with a wheel rim and tread hardness of HB330~380. Frequency conversion speed regulation allows slow speed under heavy load and fast speed under light load, with a speed regulation ratio of 1:10, ensuring smooth operation without impact.

- The trolley limit switch adopts a cross travel limit switch, reducing the trolley running speed to zero before the trolley buffer collides with the end stop of the rail.

Hoisting Mechanism

The hoisting mechanism adopts a three-point support installation. Both ends of the drum are directly supported on the end beams at both sides of the trolley frame, while the pulley beam connects the two end beams with bolts to form a longitudinal beam. The output shaft sleeve of the reducer is connected to the extended drum shaft, and the hoisting motor and reducer are connected by an elastic coupling.

- Welded Drum: The drum is a short-shaft type made of rolled steel plate, with bearing seats on both ends. One side is extended with a fitted shaft. The structure is simple, making adjustment and installation convenient.

- Hoisting Motor: Standard configuration is a frequency conversion motor with optimized air cooling design. Insulation class F, protection class IP55, duty cycle 40%.

- Hoisting Reducer: Gear surface is treated with carburizing and hardening, hardness up to HRC60, and further finished by grinding or gear shaving. It has light weight, good sealing, and no oil leakage.

- Hoisting Brake: Normally closed brake with automatic wear compensation. It can be manually released in emergency situations through independent manual operation. Dual brakes can be configured when necessary.

- Hook Group: The hook group consists of hook and pulleys. Hook material is DG34CrMo. Pulley material is Q235 hot-rolled steel, equipped with wear-resistant roller bearings. The hook can rotate 360° and is fitted with a spring-pressed safety latch to prevent disengagement. All pulleys use maintenance-free bearings, and the pulley design effectively prevents wire rope from wearing against the pulley housing. The overall structure is compact with an attractive appearance.

- Hoisting Limit Switch: Cam rotary type, 4-stage adjustable, with both upper and lower limit functions. It has automatic reset, ensuring safety and reliability. Pre-limit for lifting reduces impact, while ultimate limit prevents hook overtravel.

- Trolley Control Box: Protection class IP55, equipped with aviation plug for quick installation.

Double Girder Overhead Crane with Open Winch Installation Process:

The video includes demonstrations of advanced technologies such as module assembly, electrical wire layout, and electric trolley installation.

KUANGSHAN CRANE Double Girder Bridge Crane vs. Traditional Models: Smarter and More Efficient Choice

Compared with conventional double beam bridge cranes, KUANGSHAN CRANE double girder overhead cranes have the advantages of lighter overall weight and lower wheel pressure; compact structure and low energy consumption; modular design and intelligent operation; maintenance-free and easy operation.

- Special cold-drawn rail steel, with a rectangular solid cross-section. The distance between the top and bottom surfaces is small, ensuring uniform stress distribution, no deformation, and long service life.

- The overall height is smaller compared with traditional rails, saving the dedicated space for the trolley.

- Traditional standard rail: the middle support rib between the guide rail surface and the bottom is relatively thin, which makes it prone to deformation over time, thus affecting service life.

- The contact surface between the wheel and the rail is small, causing rapid wear on both wheels and rails.

- The overall height is large, occupying the dedicated space of the trolley.

- The end beam adopts a standard automated one-time welding-formed rectangular tube, with good mechanical performance and stable quality; compact in size, which greatly reduces the crane's spatial dimensions, thereby lowering the overall height of the workshop and saving construction costs.

- Machined by CNC automatic machining center with boring process, with small machining error, ensuring assembly precision between the end beam and the wheel.

- The main beam and the end beam are connected with 10.9-grade high-strength bolts, ensuring overall precision and stable operation.

- The end beam is spliced and welded from steel plates; the welding methods mainly include manual welding, submerged arc welding, CO₂ gas shielded welding, etc. The volume is large, and it affects the crane's spatial dimensions.

- Adopts “three-in-one” motor from internationally renowned brands, with frequency conversion drive, ensuring smooth operation.

- All-aluminum drive housing, compact size, lightweight, good heat dissipation. Modular design, direct-drive installation method, compact structure, high precision.Unique electromagnetic design effectively reduces current and extends service life.

- Equipped with a standard thermal switch to effectively improve safety level.

- Power input uses heavy-duty connectors, quick installation and removal, safe and easy to operate.

- With frequency conversion drive, running is smooth and shock-free, designed to be maintenance-free.

- The trolley traveling mechanism is driven by a motor driving a reducer. The low-speed shaft of the reducer connects in a centralized drive mode to the driving wheel mounted on the trolley frame. The motor adopts a double-shaft output, with a brake installed on one end of the shaft.

- Strong impact occurs during crane starting and stopping, with a high failure rate.

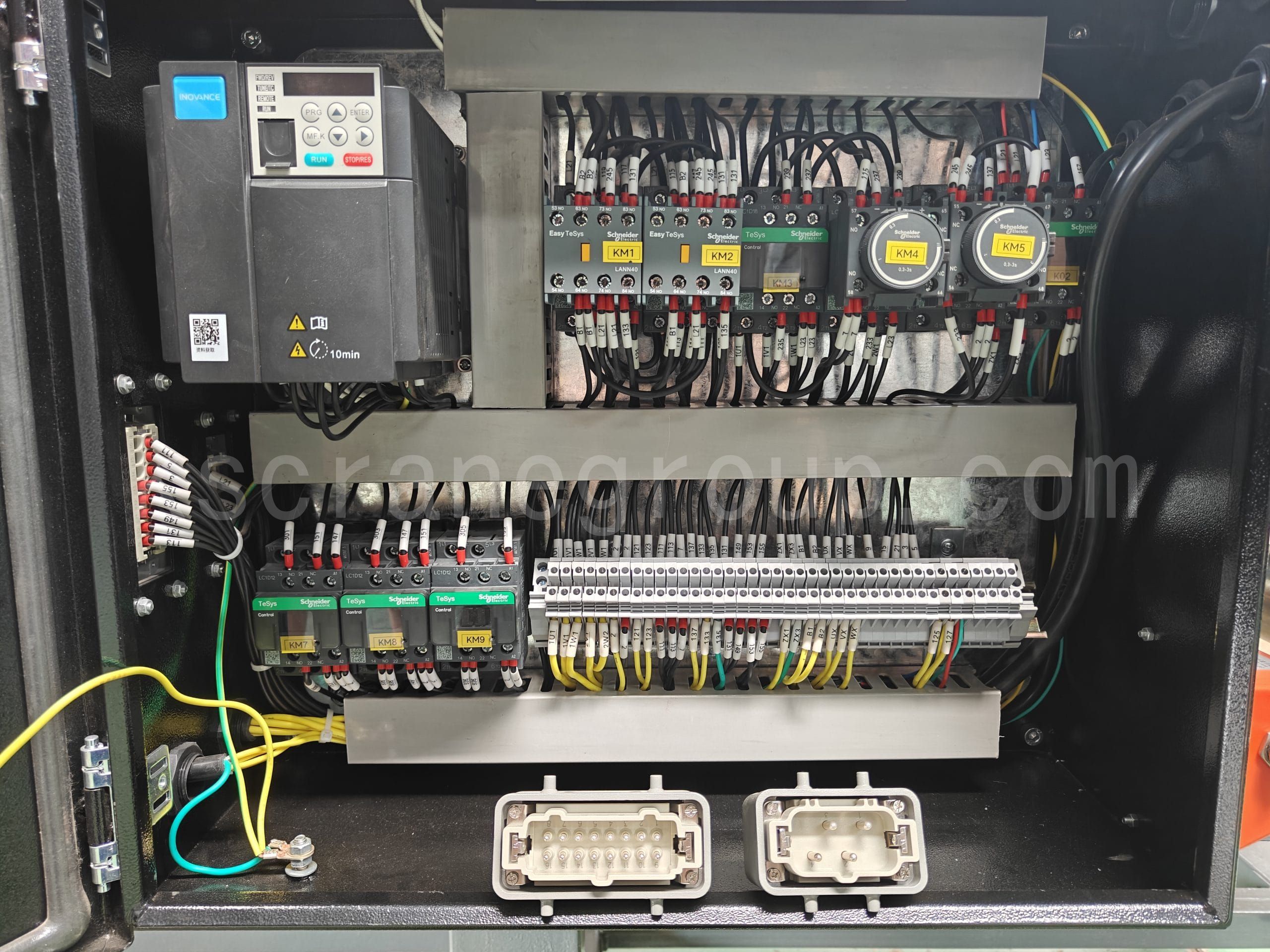

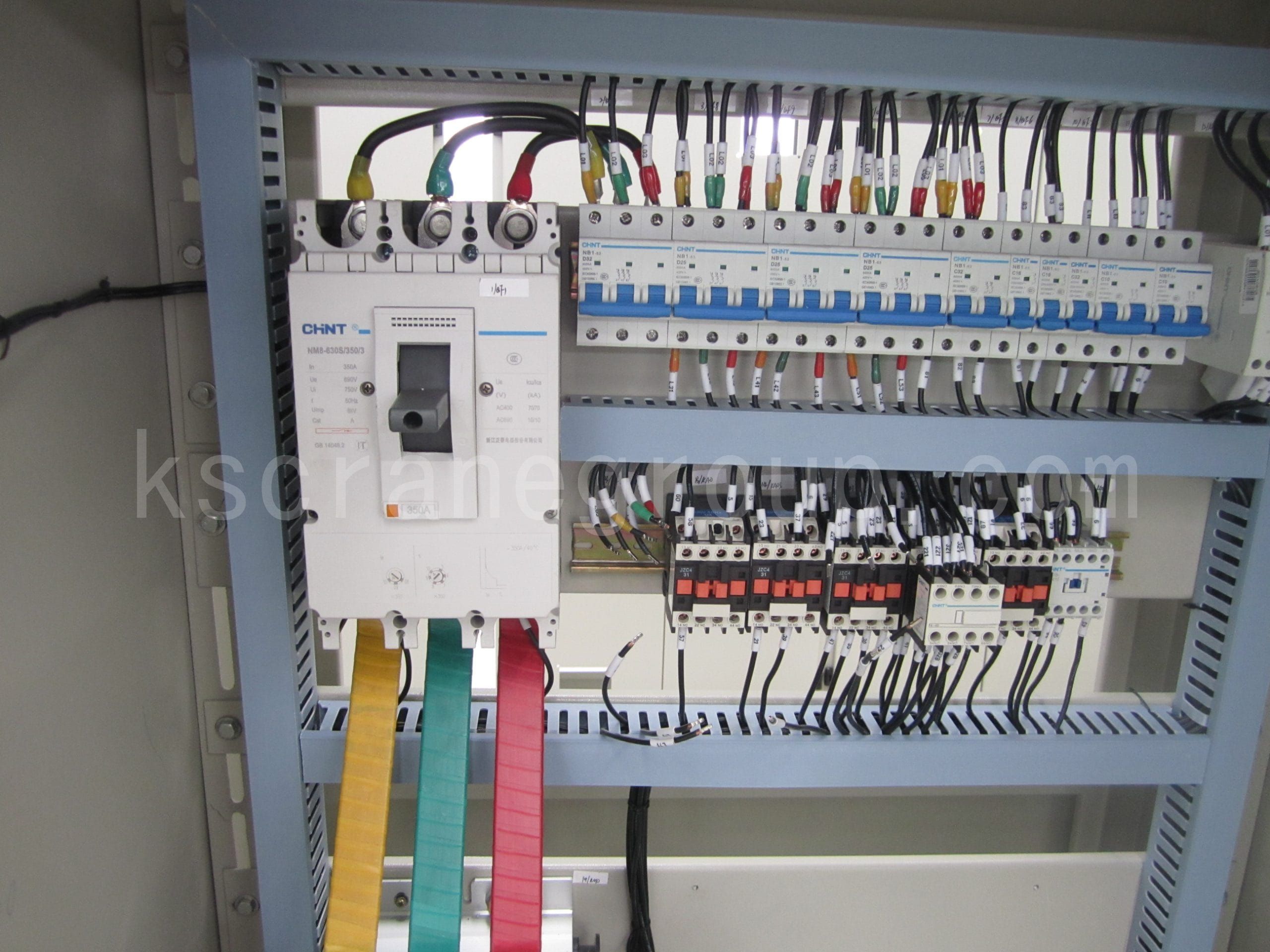

- The main trolley electrical control box is standardized, modularized, and integrated in design, easy to replace and install, with a high degree of standardization.

- Wiring is simple and reasonable, with multiple protections, protection grade IP54, noiseless, stable performance. The box cover can be opened 120° for easy maintenance.

- Main electrical components adopt Schneider, an internationally renowned brand (customizable if special requirements exist).

- Main trolley adopts frequency conversion control, and the hoisting motor adopts variable frequency speed regulation.

- Standard configuration of original imported brand limit switches, effectively ensuring safe operation and stopping.

- Aviation-grade connectors are used, ensuring very stable contact without false connections, with protection grade above IP65.

- Needs to be designed according to the model, non-general type, not easy to install, low degree of standardization.

- Wiring is not reasonable, noisy, unstable performance, low protection level.

- Mainly adopts Chint or other brands.

- Main trolley is not frequency-controlled.

- Main trolley equipped with domestic limit switch.

- Non-plug type, poor contact stability, low protection grade.

Types Of Overhead Cranes For Different Working Conditions

- Compact and novel structure, low clearance height, small overall dimensions, large working range.

- Lightweight, small wheel pressure, effectively improving stress conditions of workshop crane beam systems, and to some extent extending the service life of main load-bearing components.

- Whole machine adopts frequency conversion speed control, smooth operation, no impact, slow speed under heavy load, fast speed under light load, energy saving and environmentally friendly.

- Modular design, short design cycle, high degree of generalization, improving component utilization.

- The hoisting trolley adopts European-style electric hoist double-girder trolley.

- Composed of two 160t explosion-proof hoisting trolleys, heavy-duty bridge frame, and three-in-one drive.

- The two trolleys can lift and lower synchronously, realizing synchronous lifting and workpiece overturning operations.

- Combined with new crane design concepts, designed and manufactured to meet GB national standards and FEM European standards.

- Whole machine uses hardened gear reducer, frequency conversion drive, multiple safety protections, streamlined structure, environmentally friendly and low energy consumption.

- Lightweight, maintenance-free design.

- The reducer adopts a fully enclosed type, with high sealing performance, no oil leakage or pollution. Double-sealed brake effectively prevents contamination particles generated from motor transmission wear from leaking out.

- Entire wheel set adopts fully enclosed design. Stainless steel wheels and other parts adopt high anti-rust surface treatment, effectively preventing metal material corrosion and pollution. Self-lubricating sealed bearings avoid lubrication pollution.

- Meets the strict requirements of chemical industry lifting, military lifting, aerospace lifting, electronic equipment lifting, pharmaceutical, biotechnology, medical, and laboratory fields for production environment and quality.

- This crane is suitable for lifting and handling operations in environments containing flammable, explosive, or hazardous gases. It is widely used in industries such as oil extraction, refining, natural gas processing, chemical raw material tank handling, flour mills, and cement plants with heavy dust environments.

- The whole machine adopts explosion-proof electrical equipment.

KUANGSHAN CRANE Double Beam Overhead Crane Cases

Kuangshan Crane has delivered numerous double girder overhead crane projects worldwide, earning trust from clients across diverse industries. From Saudi Arabia to Thailand, Russia, and Bahrain, our cranes have been recognized for their high performance, precision engineering, and reliable installation services. Each case demonstrates not only the quality and adaptability of our products but also our ability to provide customized solutions and timely delivery in challenging environments.

Successful Delivery and Installation of European-style Double Girder Overhead Cranes in Saudi Arabia

A long-term customer who has always trusted our products entrusted us to supply a European double-girder crane for an important project. Given the complexity of installation and the lack of local expertise, the customer requested our assistance with installation. We dispatched a team of highly skilled engineers to the site, providing practical support throughout the entire installation process.

Our professional engineering team worked closely with the client's on-site staff to ensure smooth, efficient installation of the crane, completed within the expected timeframe. The customer was impressed by our team's professionalism, expertise, and the quality and performance of the crane. The European double-girder overhead crane met all operational requirements, providing the customer with the powerful lifting capacity and precision needed for their facility.

Two Sets Double Girder EOT Crane Export to Thailand

In 2023, an important Thai client, impressed by the performance and reliability of our products, recommended us to a new customer. After six months of discussions, negotiations, and factory inspections, the new customer decided to order their own double-girder crane from us.

However, due to tight construction schedules, the customer needed the crane urgently. The dedicated workers of Kuangshan Crane recognized the importance of meeting their needs, worked overtime, and ensured the project was completed on schedule. In just 35 days, our skilled team successfully manufactured two double-girder overhead cranes instead of one. This achievement demonstrates our commitment to excellence and our ability to deliver under demanding conditions.

Double girder EOT crane

- Capacity: 30/10t

- Span: 22.5m

- Lifting height: 12.6m

- Main Lifting apeed: 3/0.3m/min

- Aux Lifting apeed: 0.7/7m/min

- Work duty: A4 380V/50HZ/3AC

2Sets Double Girder Overhead Crane Parts Export to Russia

This was a non-standard customized project for a Russian crane plant. These special cranes were designed for aluminum plants, requiring unique modifications to meet specific environmental needs. To ensure optimal performance, we incorporated additional features such as encoders and PLC systems into the cranes.

Double girder overhead crane

- Capacity: 32/5t

- Span: 20.6m

- Lifting height: 18/20m

- Work duty: A3

Hoist Factory Approached Us To Work Together On A Bahraini Overhead Crane Project

The customer is a crane plant operating German brand cranes. We supplied the crane main beam, end carriages, and complete electrical control system to match the hoist, jointly completing this crane order. In this case, the voltage of the cross-travel motor was different from other motors, but we successfully resolved the issue. This customer is an old friend of ours with whom we have been in contact for more than two years.

NLH European Double Girder Overhead Crane

- Tonnage: 10 tons

- Span: 24.44m

When comparing European double girder overhead cranes with traditional models, the difference is clear: lighter structure, higher efficiency, lower energy consumption, and easier maintenance. For workshops and industries that demand reliability, safety, and long-term cost savings, the Fem standard design has become the preferred choice.

If you are planning to upgrade or purchase a double girder overhead crane, choosing a European type crane means investing in smarter technology and future-proof performance. Contact us today to get tailored lifting solutions that perfectly match your working conditions.

Get in Touch

- Free and fast quote for the product.

- Provide you our product catalog.

- Your local crane projects from our company.

- Become our agent and earn commission.

- Any questions, contact us.

.png?w=200&h=134)