- EQUIPMENT

-

special cranes

-

Garbage Grab Crane

-

Foundry Overhead Crane

-

Explosion-proof Overhead Crane

-

Tongs Overhead Crane

-

Overhead Crane with Carrier-beam

-

Electromagnetic Overhead Cranes

-

Diesel Hydraulic Straddle Carrier: Flexible Operation and Affordable Solution for Container Handling

-

Upper Spillway Gate Gantry Crane: Reliable Solution for Dam Gate Hoisting and Hydropower Station Operations

-

Harbour Portal Crane: Powerful and Intelligent Solutions for Efficient Port Handling

-

Coke Pot Crane for CDQ: Exceptional Heavy-Duty Red-Hot Coke Handling

-

Emergency Rescue Specialized Crane for Water-Rescue Simulation: Engineered for Lifesaving Training

-

Intelligent Grab Bucket Overhead Crane: Powerful, Precise and Unmanned Bulk Material Handling Solution

-

Custom Multi-Point Suspension Overhead Crane for Large-Span and Load-Sensitive Industrial Buildings

-

Electrolytic Copper Cranes: Specialized in Efficient Cathode Plate Tank Loading and Transfer

-

Nuclear Polar Cranes: Multi-Function Lifting Machinery For Nuclear Power Plants

-

-

Industry Crane

-

Industry Crane

-

Tundish Cranes

-

Slab Cranes

-

Scrap Cranes

-

Billet Cranes

-

Coil,Bar and Plate Handling Cranes

-

Cement And Precast Crane

-

Power Station Crane

-

Ladle Cranes

-

Paper Industry Cranes

-

Waste to Energy Cranes and Biomass Cranes

-

Tailored Overhead Cranes for Aerospace: High Precision, Efficience, Safety and Reliability

-

Anode Baking Multifunctional Cranes: Versatile, High-Temp Resistant & Smart-Controlled Must-Have for Electrolytic Aluminum Industry

-

Multifunctional Crane For Electrolytic Aluminum: Fulfills All Aluminum Electrolysis Processes, Boosts Plant Efficiency

-

Warehouse Stacker Crane for AS/RS: High-Efficiency, Reliable, Fully Automated Storage

-

Slab Handling Overhead Crane: Metallurgical-Grade Crane for Continuous Casting and Slab Yards

-

Anode Carbon Block Stacking Cranes: 6-Layer Stacking, A Lifting Solution for Carbon Plants’ Efficient Transfer

-

Quenching Crane for Heat Treatment: Process-Oriented Overhead Crane Solution

-

Safe & Stable Scrap Charging Overhead Crane for Metallurgical Feeding Operations

-

Forging Overhead Crane: Reliable Lifting Equipment for Heavy-Duty Forging Workshops

-

Mold Handling Crane for AAC Production Line: Reliable Engineered Fixed-Position Lifting Solution

-

-

Hoist & Winch Trolley

-

Casting Electric Wire Rope Hoist

-

European Model Electric Hoist

-

Explosion-proof Electric Hoist

-

Low-headroom Electric Hoist

-

Electric Chain Hoist

-

2 Types Explosion-Proof Electric Chain Hoists for Hazardous Zones: Gas & Dust Protection

-

2 Types Explosion-Proof Electric Wire Rope Hoists for Industrial Safety: Reliable Gas & Dust-Proof Solutions

-

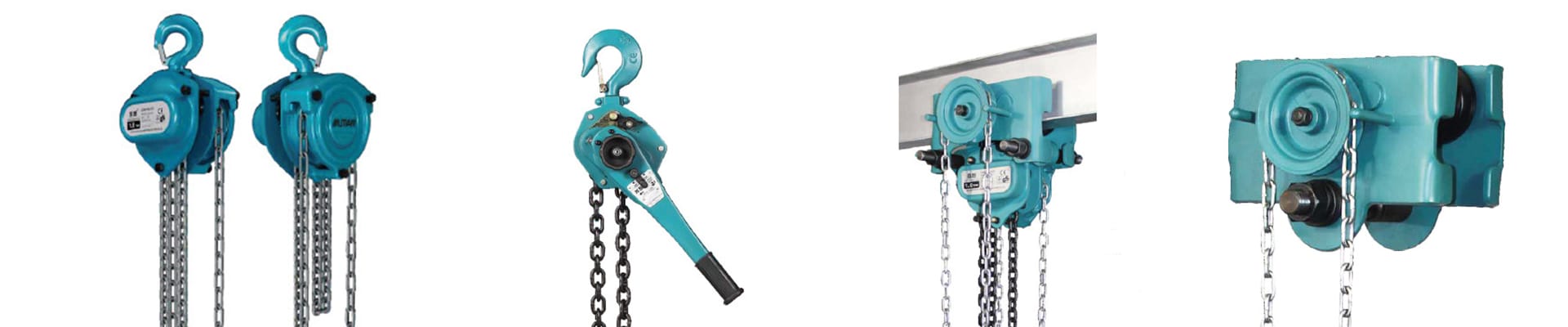

Manual Hoists for Precision Lifting: Explore 3 Proven Types for Power-Free Operation

-

Air Pneumatic Hoists: 4 Specialized Designs for Precision, Safety, and Harsh Environments

-

HC Type Electric Hoist: Heavy-duty Wire Rope Hoist for Factory Heavy Lifting

-

-

CRANE Spreader

-

Crane Electromagnetic Lifting Magnets

-

Lifting Electromagnet for Turning and Side Hung

-

Lifting Electromagnet for Thick Plate

-

Specialized Electromagnet for Lifting Steel Plates

-

Lifting Electromagnets for Lifting Steel Plates

-

Lifting Electromagnet for Heavy Rail and Profiled Steel

-

Lifting Electromagnet for High Speed Wier(Coiled Bar)

-

Lifting Electromagnet for Rebar and Steel Pipe

-

Lifting Electromagnet for Bundled Rebar and Profiled Steel

-

Lifting Electromagnet for Billet, Girder Billet and Slab

-

Lifting Electromagnet for Steel Scraps

-

- Crane Spreader

- Crane Hook

- Crane Lifting Tongs and Clamps

-

Crane Electromagnetic Lifting Magnets

- CRANE PARTS

- Transfer Cart

Manual Hoists for Precision Lifting: Explore 3 Proven Types for Power-Free Operation

Manual Hoists is a commonly used hand-operated lifting tool that lifts and lowers objects by pulling a chain. It is widely used in environments where there is no power supply or where high precision control is required. A Manual Hoist usually consists of a sprocket assembly, a manual chain, a hook, a guide frame and so on.

Manual Hoists Features:

- Manual operation: the load is lifted and lowered by hand-pulling the chain during operation, which is suitable for occasions where there is no power supply.

- Simple structure: hand chain hoist usually has a simple structure, easy to use and maintain.

- Load capacity: common hand chain hoists have different load capacities, ranging from a few hundred kilograms to several tonnes.

- Lifting method: Objects are raised and lowered manually by pulling on chains or wire ropes, which is suitable for precise control in small areas.

- Flexibility: The running hoist can be adjusted to fit different widths of track by adjusting the number of shims. It makes the installation easier and more flexible.

Manual Hoists Advantages:

- No need for electricity: suitable for working environments away from power sources, can be operated manually, reducing dependence on electricity.

- Affordable: compared with electric hoist, hand chain hoist price is cheaper, maintenance costs are relatively low.

- High safety: hand chain hoist is usually equipped with overload protection device, can effectively prevent the operation of the danger.

- Efficient and convenient: the operation can be manually controlled lifting speed, suitable for the need for fine operation occasions.

Application Scenarios:

- Warehouses and assembly lines: used in warehouses for lifting, handling and positioning heavy loads. In the assembly line, it is used for assembling and transferring machines and equipments, etc.

- Industrial manufacturing: used for lifting parts, equipment or heavy objects in the production line.

- Building construction: commonly used for moving building materials, equipment, etc. on construction sites, especially where there is no power supply.

- Repair and maintenance: used for lifting and moving machines and equipment when repairing them.

- Small ships and harbours: hand chain hoists are also widely used when lifting goods on board ships or in harbours.

Suggestions for Selection:

- Load capacity: Select the appropriate lifting capacity according to the job requirements and make sure the hoist can withstand the maximum load.

- Lifting height: Make sure the hoist can provide sufficient lifting height to meet the job requirements.

- Operating environment: Choose a model that is suitable for the operating environment, e.g. corrosion-resistant design for outdoor or humid environments.

Overall, hand chain hoists are widely used in a variety of industries where heavy loads need to be hoisted or lifted due to their economical, reliable and convenient features.

Get in Touch

- Free and fast quote for the product.

- Provide you our product catalog.

- Your local crane projects from our company.

- Become our agent and earn commission.

- Any questions, contact us.

.png?w=200&h=134)