- EQUIPMENT

-

special cranes

-

Garbage Grab Crane

-

Foundry Overhead Crane

-

Explosion-proof Overhead Crane

-

Tongs Overhead Crane

-

Overhead Crane with Carrier-beam

-

Electromagnetic Overhead Cranes

-

Diesel Hydraulic Straddle Carrier: Flexible Operation and Affordable Solution for Container Handling

-

Upper Spillway Gate Gantry Crane: Reliable Solution for Dam Gate Hoisting and Hydropower Station Operations

-

Harbour Portal Crane: Powerful and Intelligent Solutions for Efficient Port Handling

-

Coke Pot Crane for CDQ: Exceptional Heavy-Duty Red-Hot Coke Handling

-

Emergency Rescue Specialized Crane for Water-Rescue Simulation: Engineered for Lifesaving Training

-

Intelligent Grab Bucket Overhead Crane: Powerful, Precise and Unmanned Bulk Material Handling Solution

-

Custom Multi-Point Suspension Overhead Crane for Large-Span and Load-Sensitive Industrial Buildings

-

Electrolytic Copper Cranes: Specialized in Efficient Cathode Plate Tank Loading and Transfer

-

Nuclear Polar Cranes: Multi-Function Lifting Machinery For Nuclear Power Plants

-

-

Industry Crane

-

Industry Crane

-

Tundish Cranes

-

Slab Cranes

-

Scrap Cranes

-

Billet Cranes

-

Coil,Bar and Plate Handling Cranes

-

Cement And Precast Crane

-

Power Station Crane

-

Ladle Cranes

-

Paper Industry Cranes

-

Waste to Energy Cranes and Biomass Cranes

-

Tailored Overhead Cranes for Aerospace: High Precision, Efficience, Safety and Reliability

-

Anode Baking Multifunctional Cranes: Versatile, High-Temp Resistant & Smart-Controlled Must-Have for Electrolytic Aluminum Industry

-

Multifunctional Crane For Electrolytic Aluminum: Fulfills All Aluminum Electrolysis Processes, Boosts Plant Efficiency

-

Warehouse Stacker Crane for AS/RS: High-Efficiency, Reliable, Fully Automated Storage

-

Slab Handling Overhead Crane: Metallurgical-Grade Crane for Continuous Casting and Slab Yards

-

Anode Carbon Block Stacking Cranes: 6-Layer Stacking, A Lifting Solution for Carbon Plants’ Efficient Transfer

-

Quenching Crane for Heat Treatment: Process-Oriented Overhead Crane Solution

-

Safe & Stable Scrap Charging Overhead Crane for Metallurgical Feeding Operations

-

Forging Overhead Crane: Reliable Lifting Equipment for Heavy-Duty Forging Workshops

-

Mold Handling Crane for AAC Production Line: Reliable Engineered Fixed-Position Lifting Solution

-

-

Hoist & Winch Trolley

-

Casting Electric Wire Rope Hoist

-

European Model Electric Hoist

-

Explosion-proof Electric Hoist

-

Low-headroom Electric Hoist

-

Electric Chain Hoist

-

2 Types Explosion-Proof Electric Chain Hoists for Hazardous Zones: Gas & Dust Protection

-

2 Types Explosion-Proof Electric Wire Rope Hoists for Industrial Safety: Reliable Gas & Dust-Proof Solutions

-

Manual Hoists for Precision Lifting: Explore 3 Proven Types for Power-Free Operation

-

Air Pneumatic Hoists: 4 Specialized Designs for Precision, Safety, and Harsh Environments

-

HC Type Electric Hoist: Heavy-duty Wire Rope Hoist for Factory Heavy Lifting

-

-

CRANE Spreader

-

Crane Electromagnetic Lifting Magnets

-

Lifting Electromagnet for Turning and Side Hung

-

Lifting Electromagnet for Thick Plate

-

Specialized Electromagnet for Lifting Steel Plates

-

Lifting Electromagnets for Lifting Steel Plates

-

Lifting Electromagnet for Heavy Rail and Profiled Steel

-

Lifting Electromagnet for High Speed Wier(Coiled Bar)

-

Lifting Electromagnet for Rebar and Steel Pipe

-

Lifting Electromagnet for Bundled Rebar and Profiled Steel

-

Lifting Electromagnet for Billet, Girder Billet and Slab

-

Lifting Electromagnet for Steel Scraps

-

- Crane Spreader

- Crane Hook

- Crane Lifting Tongs and Clamps

-

Crane Electromagnetic Lifting Magnets

- CRANE PARTS

- Transfer Cart

Safe & Stable Scrap Charging Overhead Crane for Metallurgical Feeding Operations

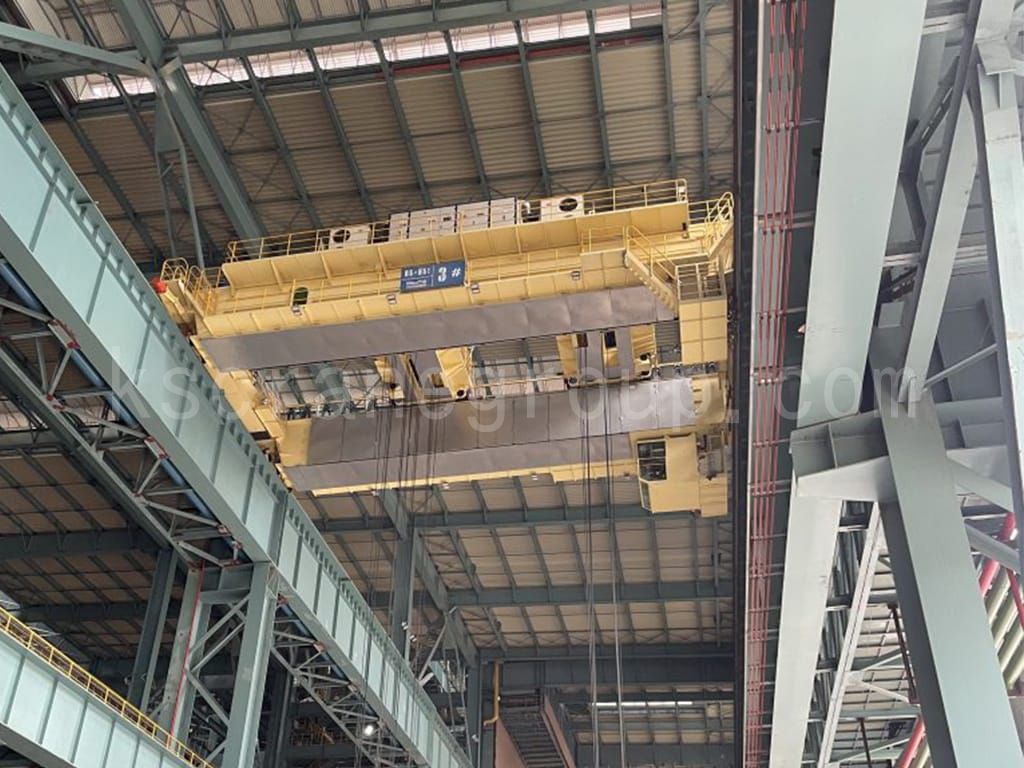

The charging overhead crane is a bridge-type crane specifically designed for the metallurgical industry. It is primarily used for material transfer and charging operations during the smelting process.

The crane is capable of performing charging box lifting, transferring, and tilting operations, and is widely applied in typical metallurgical production scenarios such as basic oxygen furnace (BOF) steelmaking and electric arc furnace (EAF) steelmaking.

This type of crane is classified with a duty class of A6–A7, making it suitable for high-temperature, heavy-load, and high-frequency operations commonly found in metallurgical workshops. It is a typical metallurgical-grade overhead crane.

- Rated Capacity: 20+20 t ~ 110+110 t

- Span: 18 m ~ 30 m

- Lifting Height: 24 m ~ 30 m

Functions and Applications of Scrap Charging Overhead Crane

BOF Steelmaking Application: During the basic oxygen furnace steelmaking process, the charging overhead crane is mainly used to add cold materials into the converter. Charging boxes are utilized for lifting and feeding scrap steel and auxiliary materials into the furnace.

EAF Steelmaking Application: In electric arc furnace operations, the scrap charging overhead crane is primarily used for charging scrap steel into the furnace. Compared with casting cranes, the main hoisting mechanism does not need to meet single-crane operation requirements, making it more suitable for the specific characteristics of charging operations.

Core Advantages and Key Features

1. Control System and Operation Configuration

- Combined control console integrated with PLC modules

- Equipped with a human-machine interface (HMI) touch screen

- The WLK-type master controller adopted

- Clear operating feedback and distinct control positions

- Zero-position self-reset and locking protection functions

2. High-Temperature Operating Capability

- Key components made of high-temperature-resistant materials or protected with thermal insulation covers

- Capable of withstanding radiant heat near the furnace mouth

- Motor insulation class reaches Class H

- Ensures stable and reliable operation in high-temperature environments

3. Extended Service Life of Wheels and Critical Components

- Crane wheels are manufactured using a forged and rolled composite process

- Compared with conventional forged wheels, the service life is increased by approximately 20%

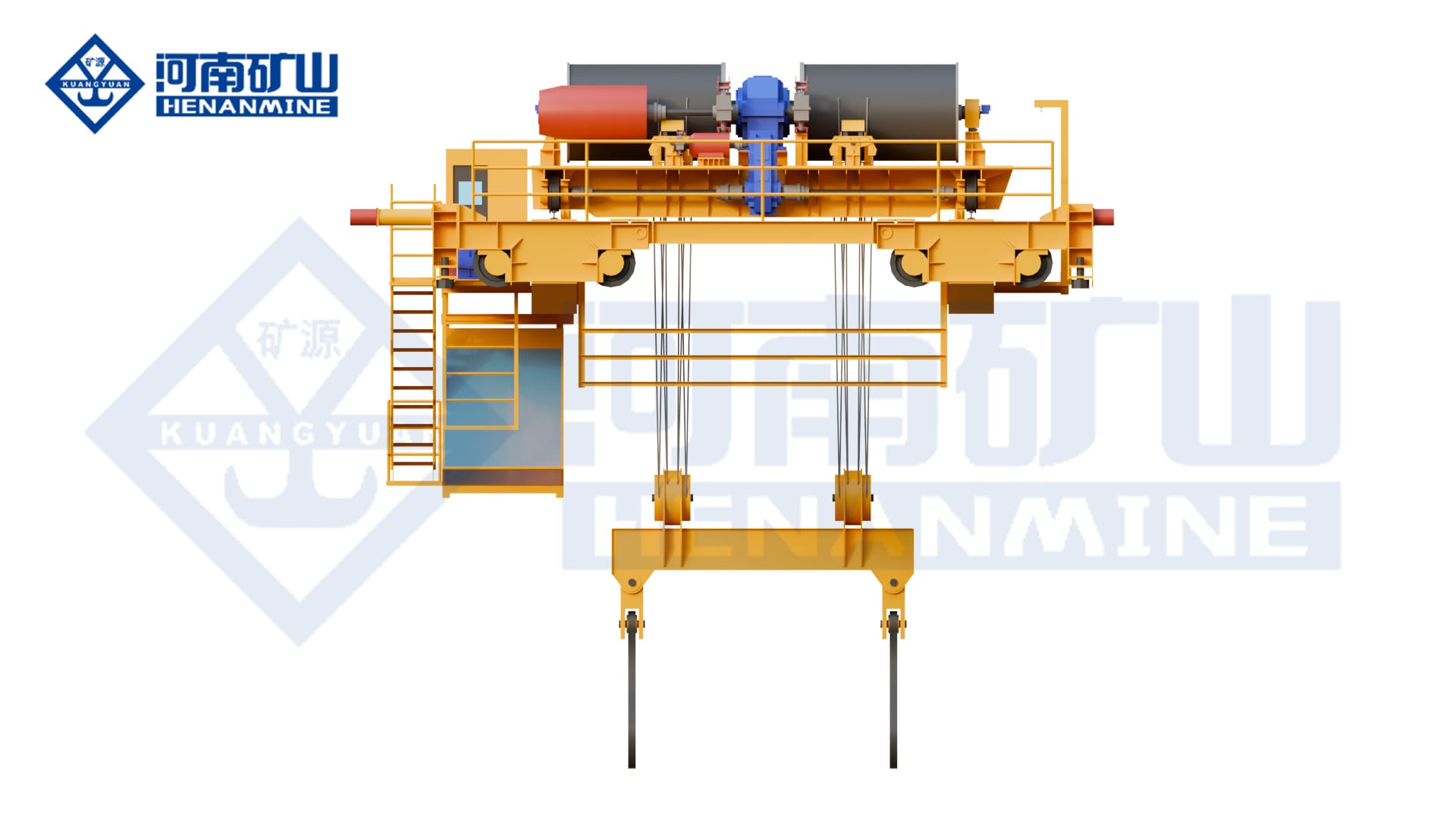

4. Integrated Hoisting and Charging Functions

- Hoisting mechanism equipped with an electronic weighing system for real-time display and statistical recording of lifted material weight

- The dual-trolley electrical control system enables:

- Charging box tilting

- Synchronous lifting

- Synchronous traveling

Structural Configurations

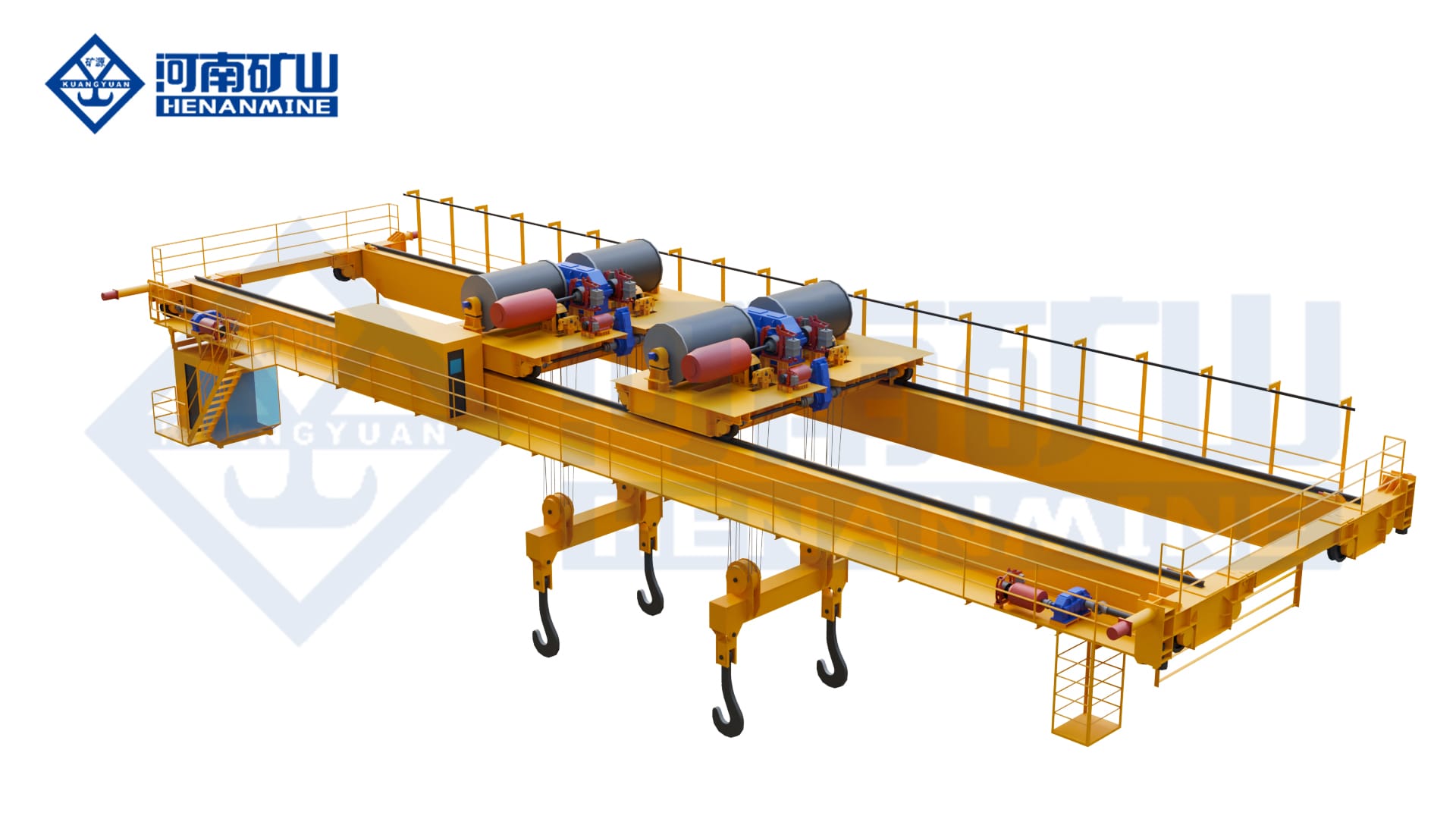

Charging overhead cranes mainly adopt a double-girder bridge structure. According to the trolley arrangement, two configurations are available:

Double-Girder Single Trolley Design

- Lightweight structure with compact overall dimensions

- Two hoisting mechanisms are arranged on the same trolley

- Trolley travels on rails mounted on two main girders

Double-Girder Double Trolley Design

- Balanced load distribution on the main girders

- Two hoisting mechanisms are arranged on separate trolleys

- The two trolleys can operate synchronously or independently

In addition, customized charging overhead crane solutions can be designed, manufactured, installed, and commissioned according to specific customer processes and site conditions.

Kuangshan Charging Overhead Cranes – Standards and Technical Specifications

The design, manufacturing, assembly, and testing of charging overhead cranes comply with JB/T 7688.2-2008 “Scrap Charging Crane”, a national industry standard. Key technical requirements include, but are not limited to the following:

1. Environmental Conditions

- Operating ambient temperature: –10 °C to +50 °C

- Relative humidity not exceeding 50% at +40 °C

2. Requirements for Main Components

- Material properties of steel brake wheels shall not be lower than 45 steel specified in GB/T 699 or ZG310-570 steel specified in GB 11352

- Forged wheels or rolled wheels are recommended

- Wheel tread hardness, hardened layer depth, and dimensional tolerances shall comply with relevant standards

- Important metal structural components shall undergo surface shot blasting (or sand blasting) before welding, achieving Sa2½ grade as specified in GB/T 8923; other components shall reach Sa 2 or St 2 grade

3. Bridge Structure and Assembly Accuracy

- Strict control requirements for main girder camber, rail gauge, diagonal deviation, and trolley rail elevation differences

- The maximum allowable deviation of trolley wheel gauge shall not exceed ±3 mm

4. Electrical and Safety Requirements

- Standard crane electrical control equipment adopted

- Motors compliant with JB/T 10104 and JB/T 10105 for crane and metallurgical applications

- Class H insulated motors selected for environments exceeding +40 °C

- Safety protection devices installed in accordance with GB 6067

- Crane equipped with travel limiters, rail sweepers, buffers, and end stops at trolley track ends, with firmly welded stop heads

Kuangshan Charging Cranes – Testing and Acceptance

Qualified testing is conducted using a step-by-step loading method to verify the functionality of each mechanism under rated voltage and rated speed.

- Static Load Test: Conducted at 1.25 × rated load, checking the main girder for any permanent deformation after testing

- Dynamic Load Test: Conducted at 1.1 × rated load, requiring smooth operation of all mechanisms without jamming or abnormal behavior

Summary

The charging overhead crane is a specialized bridge crane strictly designed according to metallurgical process requirements. Its structural configuration, duty class, material selection, and control system are all optimized for steelmaking charging operations.

By meeting the demanding conditions of high temperature and heavy loads, the crane ensures safe, stable, and controllable charging operations, making it one of the key pieces of production equipment in modern steelmaking workshops.

Get in Touch

- Free and fast quote for the product.

- Provide you our product catalog.

- Your local crane projects from our company.

- Become our agent and earn commission.

- Any questions, contact us.

.png?w=200&h=134)