- EQUIPMENT

-

special cranes

-

Garbage Grab Crane

-

Foundry Overhead Crane

-

Explosion-proof Overhead Crane

-

Tongs Overhead Crane

-

Overhead Crane with Carrier-beam

-

Electromagnetic Overhead Cranes

-

Diesel Hydraulic Straddle Carrier: Flexible Operation and Affordable Solution for Container Handling

-

Upper Spillway Gate Gantry Crane: Reliable Solution for Dam Gate Hoisting and Hydropower Station Operations

-

Harbour Portal Crane: Powerful and Intelligent Solutions for Efficient Port Handling

-

Coke Pot Crane for CDQ: Exceptional Heavy-Duty Red-Hot Coke Handling

-

Emergency Rescue Specialized Crane for Water-Rescue Simulation: Engineered for Lifesaving Training

-

Intelligent Grab Bucket Overhead Crane: Powerful, Precise and Unmanned Bulk Material Handling Solution

-

Custom Multi-Point Suspension Overhead Crane for Large-Span and Load-Sensitive Industrial Buildings

-

Electrolytic Copper Cranes: Specialized in Efficient Cathode Plate Tank Loading and Transfer

-

Nuclear Polar Cranes: Multi-Function Lifting Machinery For Nuclear Power Plants

-

-

Industry Crane

-

Industry Crane

-

Tundish Cranes

-

Slab Cranes

-

Scrap Cranes

-

Billet Cranes

-

Coil,Bar and Plate Handling Cranes

-

Cement And Precast Crane

-

Power Station Crane

-

Ladle Cranes

-

Paper Industry Cranes

-

Waste to Energy Cranes and Biomass Cranes

-

Tailored Overhead Cranes for Aerospace: High Precision, Efficience, Safety and Reliability

-

Anode Baking Multifunctional Cranes: Versatile, High-Temp Resistant & Smart-Controlled Must-Have for Electrolytic Aluminum Industry

-

Multifunctional Crane For Electrolytic Aluminum: Fulfills All Aluminum Electrolysis Processes, Boosts Plant Efficiency

-

Warehouse Stacker Crane for AS/RS: High-Efficiency, Reliable, Fully Automated Storage

-

Slab Handling Overhead Crane: Metallurgical-Grade Crane for Continuous Casting and Slab Yards

-

Anode Carbon Block Stacking Cranes: 6-Layer Stacking, A Lifting Solution for Carbon Plants’ Efficient Transfer

-

Quenching Crane for Heat Treatment: Process-Oriented Overhead Crane Solution

-

Safe & Stable Scrap Charging Overhead Crane for Metallurgical Feeding Operations

-

Forging Overhead Crane: Reliable Lifting Equipment for Heavy-Duty Forging Workshops

-

Mold Handling Crane for AAC Production Line: Reliable Engineered Fixed-Position Lifting Solution

-

-

Hoist & Winch Trolley

-

Casting Electric Wire Rope Hoist

-

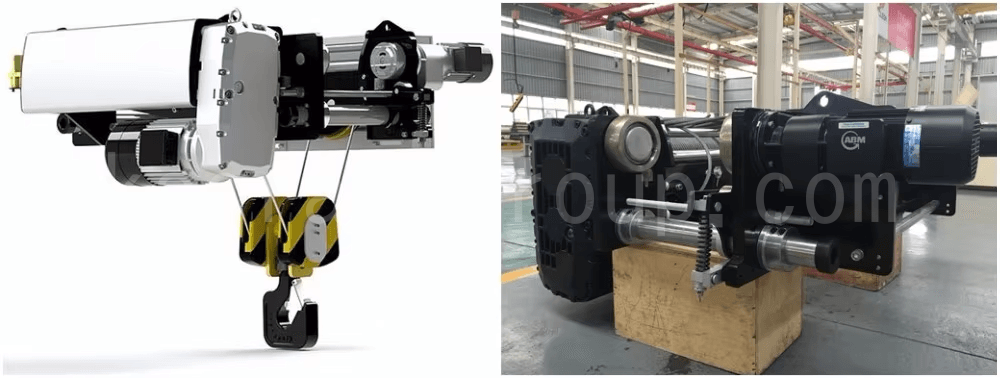

European Model Electric Hoist

-

Explosion-proof Electric Hoist

-

Low-headroom Electric Hoist

-

Electric Chain Hoist

-

2 Types Explosion-Proof Electric Chain Hoists for Hazardous Zones: Gas & Dust Protection

-

2 Types Explosion-Proof Electric Wire Rope Hoists for Industrial Safety: Reliable Gas & Dust-Proof Solutions

-

Manual Hoists for Precision Lifting: Explore 3 Proven Types for Power-Free Operation

-

Air Pneumatic Hoists: 4 Specialized Designs for Precision, Safety, and Harsh Environments

-

HC Type Electric Hoist: Heavy-duty Wire Rope Hoist for Factory Heavy Lifting

-

-

CRANE Spreader

-

Crane Electromagnetic Lifting Magnets

-

Lifting Electromagnet for Turning and Side Hung

-

Lifting Electromagnet for Thick Plate

-

Specialized Electromagnet for Lifting Steel Plates

-

Lifting Electromagnets for Lifting Steel Plates

-

Lifting Electromagnet for Heavy Rail and Profiled Steel

-

Lifting Electromagnet for High Speed Wier(Coiled Bar)

-

Lifting Electromagnet for Rebar and Steel Pipe

-

Lifting Electromagnet for Bundled Rebar and Profiled Steel

-

Lifting Electromagnet for Billet, Girder Billet and Slab

-

Lifting Electromagnet for Steel Scraps

-

- Crane Spreader

- Crane Hook

- Crane Lifting Tongs and Clamps

-

Crane Electromagnetic Lifting Magnets

- CRANE PARTS

- Transfer Cart

Single Girder Overhead Crane: European Design for Unmatched Efficiency and Durability

The design, manufacturing, and inspection of the single girder overhead crane comply with relevant national standards, while also adopting certain foreign standards, such as FEM, DIN, and IEC. The main beam and end beam adopt a welded box-type beam structure, with the lower flange plate serving as the running track for the electric hoist. The main beam and end beam are connected using high-strength bolts, facilitating transportation and on-site installation. The hoisting mechanism employs a new type of electric hoist, featuring a compact structure and easy maintenance.

- Greater Durability: Lightweight design and low wheel pressure effectively improve the stress conditions of the workshop's crane beam system, extending the service life of main load-bearing components to a certain extent.

- Improved Efficiency: The entire crane adopts variable frequency speed control, ensuring smooth operation without impact, with slow speed for heavy loads and fast speed for light loads.

- Low Headroom Height: Compact and innovative structure, small overall dimensions, and large working range.

Single Girder Overhead Crane Specifications

Here you can find the key single beam overhead crane specifications, including capacity, span, lifting height, and working class.

- Lifting capacity: 1t~20t

- Span: 9.5m~24m

- Lifting height: 6m~18m

- Working group: A4、A5

For full details, download the complete specifications PDF.

Single Girder Overhead Crane Price List

The standard specification configuration of the european single beam bridge cranes includes:

- The main girder is european-style square girder, which can be adapted to european-style hoist, CD, MD low headroom hoist, the end girder is european-style end girder, european-style wheels;

- The motor is equipped with German imported motor, and the running mechanism adopts frequency conversion speed regulation.

| Lifting Capacity | Span/m | Lifting Height/m | Price/USD |

|---|---|---|---|

| 1 ton | 9.5-24 | 6-18 | $5,000-9,500 |

| 2 ton | 9.5-24 | 6-18 | $5,200-9,600 |

| 3 ton | 9.5-24 | 6-18 | $5,300-10,300 |

| 5 ton | 9.5-24 | 6-18 | $5,900-11,000 |

| 10 ton | 9.5-24 | 6-18 | $7,800-15,000 |

| 16 ton | 9.5-24 | 6-18 | $11,000-19,000 |

Note: The above is the standard specification single girder overhead crane price list. Industrial Machinery products are subject to market changes and are for reference only.

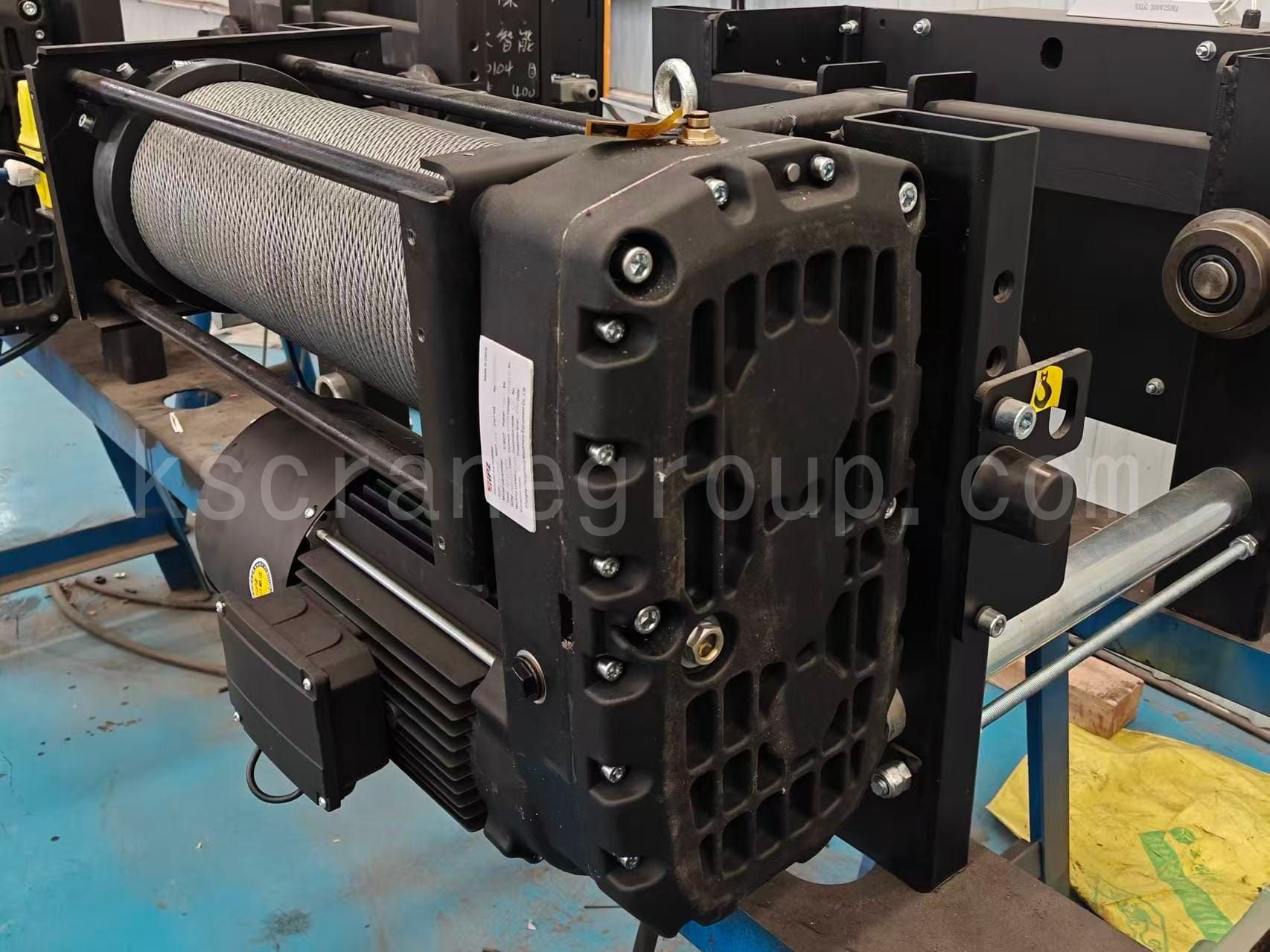

Hoisting Mechanism Features

Utilizes imported German hoisting motors and reducers. The integrated compact design of the hoisting motor, reducer, drum, and lifting limit switch saves user space. The modular design enhances the mechanism’s reliability while effectively reducing maintenance time and costs.

The hoisting mechanism provides faster lifting speeds and a variety of pulley ratio options to choose from. The standard trolley traveling mechanism utilizes variable frequency control, reaching speeds of up to 20 meters per minute. This ensures minimal load sway during trolley movement and precise positioning, making it safe and reliable for hoisting delicate and valuable items.

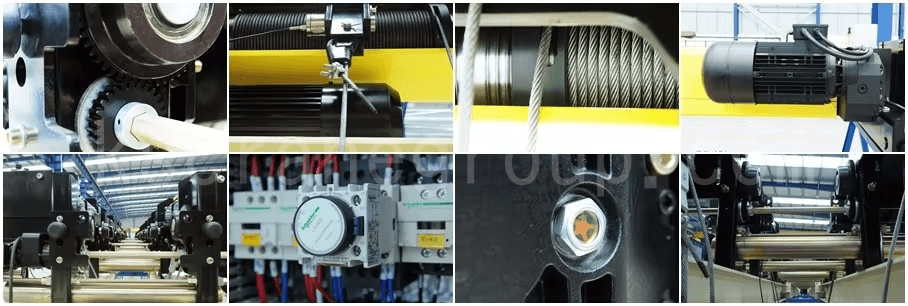

Drum

The drum is crafted from high-quality seamless steel pipes using CNC machining. After precision processing, the rope grooves on the drum, combined with a rope guide, effectively prevent rope loosening and tangling.

Wire Rope

The wire rope is a high-strength imported wire rope with a nominal tensile strength of 2160 kN/mm², offering excellent safety and a long service life.

Rope Guide

The standard rope guide is made from engineering plastic with high wear resistance and self-lubricating properties, significantly reducing wear on the wire rope—a critical load-bearing safety component—thereby enhancing the safety of the hoisting mechanism. Additionally, for varying operational conditions, a heavy-duty rope guide made from ductile cast iron is also available.

Hoisting Motor

The hoisting mechanism employs a dual-winding squirrel-cage variable-pole motor, achieving a 1:6 fast-to-slow speed ratio. The motor housing is made of aluminum alloy through extrusion, providing excellent heat dissipation. A fan is installed at the motor’s end to enhance cooling performance. All hoisting motor windings are embedded with thermistors (or thermal switches) to prevent potential motor overheating. The motor has an insulation rating of Class F and a protection rating of IP54. For variable frequency hoisting motors, an encoder can be installed, typically mounted directly on the fan shaft end of the motor.

Technical Features:

- Low starting current, high torque

- Soft start with excellent acceleration performance

- Long design service life

- Technical parameters comply with FEM and HMI standards

- High speed, low noise

Brake

The hoisting motor is equipped with a dual-disc electromagnetic brake. The brake is integrated at the motor’s end and automatically engages when the motor loses power, preventing load slippage. The brake clearance is self-adjusting through the brake spring after initial setup, requiring no manual adjustment. When the brake pad thickness falls below the set value, an additional monitoring switch automatically triggers an alarm to prompt replacement. The dual-disc electromagnetic brake is safe and reliable, with a braking torque at least 1.8 times the motor’s rated torque. It can withstand up to 1 million braking cycles and requires no maintenance within its safe service life.

Technical Features:

- Fast response, high reliability

- Maintenance-free, self-adjusting

- Dust-proof design, long service life

Reducer

The reducer housing is made of aluminum alloy, offering light weight and corrosion resistance. The fully sealed housing contains semi-grease lubricant, ensuring all gears are adequately lubricated, with no need for lubricant replacement within the designed safe service life. Each gear, surface-hardened and precision-ground, ensures smooth operation of the reducer.

Technical Features:

- Compact size, light weight

- Smooth operation, low noise

- Corrosion-resistant, maintenance-free

Safety Protection

- Upper and Lower Limit Switch: The wire rope electric hoist employs a precise gear-driven limit switch. When the hook reaches the upper or lower limit position, it reliably cuts off the power circuit to stop the motor.

- Overload Protector: The wire rope electric hoist is equipped with an electronic overload protector (with a safety monitor) to ensure the total lifting weight does not exceed the rated capacity of the crane. When the wire rope tension exceeds 105% of the rated value, the overload protection device automatically cuts off the hoisting circuit.

- Safety Monitor: Depending on user requirements, it can perform multiple functions, including calculating the remaining safe working cycles of the hoisting mechanism, tracking cumulative hoisting operation time, recording cumulative overload occurrences, monitoring cumulative hoisting motor start times, providing motor overheating protection and alarms, overload protection and alarms, brake pad thickness alarms, and displaying fault information and maintenance prompts.

Comparison Between KUANGSHAN CRANE HD Single Girder Overhead Crane and LD Single Girder Overhead Crane

Compared with conventional single girder overhead cranes, the European-style single girder crane features lighter overall weight and lower wheel pressure; a compact structure with reduced energy consumption; modular design with intelligent operation; maintenance-free and user-friendly advantages.

HD Single Girder Overhead Crane

LD Single Girder Overhead Crane

- The main beam and end beams adopt a welded box-type structure, connected with high-strength bolts.

- The main beam is formed by rolled steel plates into a U-shaped groove or assembled into a box-type structure.

- Equipped with a “three-in-one” motor with frequency conversion drive, ensuring smooth operation.

- Full aluminum drive housing, compact in size, lightweight, and with excellent heat dissipation. Modular design with direct-drive installation for high precision.

- Unique electromagnetic design effectively reduces current and extends service life.

- Standard thermal switch significantly enhances safety.

- Power input uses heavy-duty connectors, allowing quick connection/disconnection, safe and easy to operate.

- The trolley and crane travelling mechanism is driven by an electric motor connected to a reducer. The reducer's low-speed shaft adopts a centralized drive method, linking to the driven wheels mounted on the trolley frame. The motor features a double-ended output shaft, with a brake installed on one end of the shaft.

- The crane experiences strong impact shocks during starting and stopping, resulting in a high failure rate.

- The hoisting mechanism adopts a new type of electric hoist with a compact structure and easy maintenance. It consists of a dual-speed motor, a hard-tooth surface reducer with an aluminum alloy housing, drum, wire rope, hook, and lifting limit switch. Featuring an integrated compact design with a C-type layout, the motor and drum are arranged in parallel.

- The wire rope electric hoist is an integrated lifting device composed of a motor, reducer, and brake. It operates by winding and unwinding a flexible wire rope on the drum to raise and lower the lifting attachment.

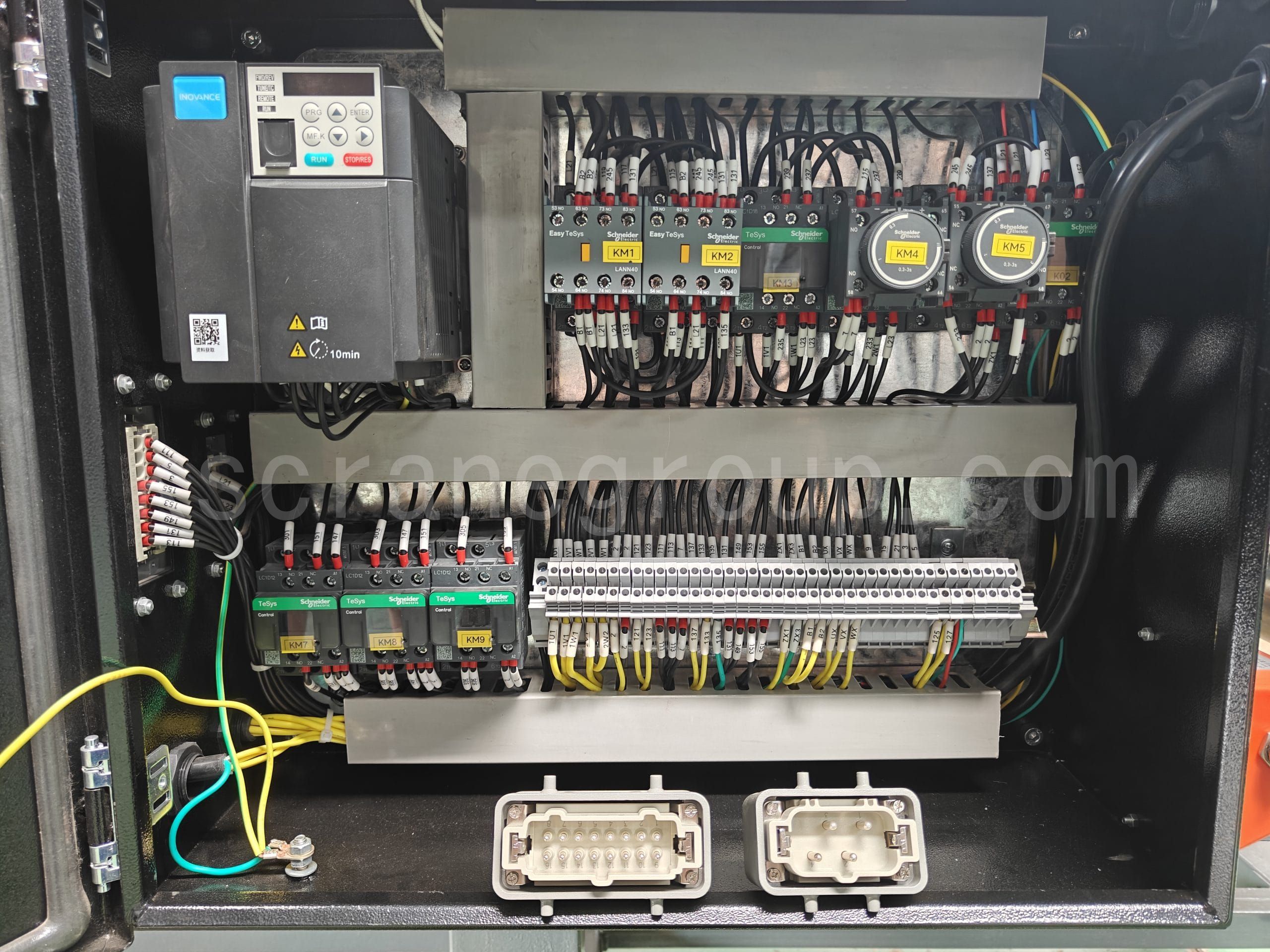

- The main trolley electrical control box adopts a standardized, modular, and integrated design, making replacement and installation easy with a high degree of standardization.

- Wiring is simple and logical, with multiple protection features, protection grade IP54, noise-free, stable performance, and a 120° opening box cover for convenient maintenance.

- The main trolley is equipped with frequency conversion control.

- Requires vehicle-specific design, non-universal, difficult to install, and has a low degree of standardization.

- High noise, unstable performance, and low protection grade.

- The main trolley is not equipped with frequency conversion control.

Single Girder Overhead Crane Installation Process

The video below shows the single girder bridge crane installation process, covering each key step of on-site assembly. It highlights how KUANGSHAN CRANE ensures a safe, efficient, and precise installation.

KUANGSHAN CRANE Single Girder Overhead Crane Cases

KUANGSHAN CRANE's Single-Girder Overhead Crane has been widely applied in multiple countries and regions, including Ethiopia, Sri Lanka, Indonesia, and Saudi Arabia, covering solutions ranging from customized large-span designs to corrosion-resistant marine environment designs, as well as rapid delivery and flexible configurations. These successful cases fully demonstrate KUANGSHAN CRANE's strengths in innovative design, reliable performance, and global service capabilities, earning long-term trust and continued cooperation from clients.

5-Ton HD Type Overhead Crane for Ethiopian Market: Tailored Solution for 27m Span

This is a new customer referred to us by a long-term trusted client from Ethiopia, who has successfully purchased an HD-type single-girder 5-ton overhead crane from our company. Given the crane's span of up to 27 meters, the new customer naturally had concerns about the logistics of transporting such a long main beam. Long-distance transportation of such a large component poses significant challenges. To address this issue, our experienced engineering team devised an innovative solution. We decided to divide the main beam into three segments, each 11.8 meters long. Upon arrival at the installation site, our professional technicians used high-strength bolts and flange plates to precisely connect the segments at the cutting points. This connection method ensures extremely high strength at the joints. We conducted extensive testing and engineering analysis to guarantee the quality of these connections. As a result, the crane's integrity and performance remain unaffected, and the customer can rest assured that there will be no issues with the connection quality.

Model: HD Type Europe Single Girder Overhead Crane

- Capacity: 5 tons

- Span: 27.76m

- Lifting height: 10.5m

- Lifting speed: 0.8/5m/min (slow/fast speed)

- Cross traveling speed: 2-20m/min (VFD speed)

- Long traveling speed: 3-30m/min (VFD speed)

- Main electrical components: Schneider

- Inverter for cross travel and long travel: Schneider

- Motors: Top brand from China

- Crane work duty: FEM 2m

- Control method: Pendant control

- Power supply: 380V 50HZ 3PH

Custom 7.5-Ton HD Type Overhead Crane for Sri Lanka: Designed for Harsh Marine Conditions

A key client from Sri Lanka ordered a 7.5-ton HD-type European single-girder overhead crane. This crane was specifically designed to meet the needs of the client's factory, located near the coast and facing significant corrosion challenges due to the marine environment. To address this issue, we recommended the use of corrosion-resistant coatings to ensure the crane's durability and reliable performance under harsh conditions. This extends the crane's service life and minimizes maintenance requirements.

Model: HD Type Europe Single Girder Overhead Crane

- Capacity: 7.5 tons

- Span: 14,106mm

- Lifting height: 8m

- Lifting speed: 0.8/5m/min (slow/fast speed)

- Cross traveling speed: 2-20m/min (VFD speed)

- Long traveling speed: 3-30m/min (VFD speed)

- Main electrical components: Schneider

- Inverter for cross travel and long travel: Schneider

- Motors: Top brand from China

- Crane work duty: FEM 2m

2 Sets HD Single Girder Overhead Cranes Exported to Indonesia

On November 15, 2024, we received the first inquiry from the client, who expressed their intention to manufacture the main beam themselves and have us provide the remaining components. We provided the client with a quotation. Later, the client's engineer contacted us, and we patiently addressed various questions they had. On December 6, the client informed us that their boss was very satisfied with our pricing and products, leading them to purchase two complete cranes at once.

Crane specification:

- Crane capacity: 3T&5T

- Crane model: HD

- Span length: 9.15m

- Lifting height: 6m

- Work duty: A5

- Power source: 380V/50Hz/3Ph

- Control mode: Pendant + remote control

10 Ton Single Girder Overhead Crane Exports to Saudi Arabia

This is a repeat order from a valued long-term client for two HD-type European single-girder overhead cranes. Our client is a crane distributor in Germany, and our experienced engineers, with their extensive expertise, resolved voltage issues related to the controller and motor for the client. The client has chosen us as their preferred supplier and expressed their intention to place more orders with us in the future.

Model: European single girder overhead crane (without electric hoist)

- Capacity: 10 ton

- Span: 12.825m

- Lift height: 6m

- Long travel speed: 3.2-32m/min

- Control way: pendent control

- Work duty: FEM 2M

- Long travel motor: SEW

- Main electrical component: Schneider

- Inverter brand: Schneider

- Power supply: 380V 60HZ 3PH

Overhead Crane Exported to Saudi Arabia

KUANGSHAN CRANE is honored to announce the successful receipt of a repeat order from a long-term industrial partner in Saudi Arabia, fully demonstrating the trust earned by KUANGSHAN CRANE through its exceptional technology.

Model: HD type Europe single girder overhead crane

- Capacity: 5 ton

- Span: 16.8m

- Lifting height: 15m

- Main lifting speed: 5.3/0.9m/min (fast/slow speed)

- Cross traveling speed: 5-20m/min (VFD speed)

- Long traveling speed: 3-30m/min (VFD speed)

- Crane work duty: FEM 2m

Model: HD type Europe single girder overhead crane

- Capacity: 3 ton

- Span: 17.25m

- Lifting height: 6m

- Main lifting speed: 5.1/0.9m/min (fast/slow speed)

- Cross traveling speed: 2-20m/min (VFD speed)

- Long traveling speed: 3-30m/min (VFD speed)

- Crane work duty: FEM 2m

The control method for both single-girder overhead cranes is remote control + pendant control, with a power supply of 380V, 60Hz, 3-phase. The inverters and main electrical components are from Schneider, and the motors are from SEW.

KUANGSHAN CRANE's Single Girder Overhead Crane combines advanced European technology, modular design, and premium components to deliver a solution that is lightweight, energy-efficient, low-maintenance, and highly reliable. With proven applications across Ethiopia, Sri Lanka, Indonesia, Saudi Arabia, and beyond, our cranes have demonstrated outstanding adaptability in diverse industries and working environments.

If you are looking for a cost-effective, durable, and globally trusted lifting solution, KUANGSHAN CRANE is your reliable partner to support your projects with world-class quality and service.

Get in Touch

- Free and fast quote for the product.

- Provide you our product catalog.

- Your local crane projects from our company.

- Become our agent and earn commission.

- Any questions, contact us.

.png?w=200&h=134)