- EQUIPMENT

-

special cranes

-

Garbage Grab Crane

-

Foundry Overhead Crane

-

Explosion-proof Overhead Crane

-

Tongs Overhead Crane

-

Overhead Crane with Carrier-beam

-

Electromagnetic Overhead Cranes

-

Diesel Hydraulic Straddle Carrier: Flexible Operation and Affordable Solution for Container Handling

-

Upper Spillway Gate Gantry Crane: Reliable Solution for Dam Gate Hoisting and Hydropower Station Operations

-

Harbour Portal Crane: Powerful and Intelligent Solutions for Efficient Port Handling

-

Coke Pot Crane for CDQ: Exceptional Heavy-Duty Red-Hot Coke Handling

-

Emergency Rescue Specialized Crane for Water-Rescue Simulation: Engineered for Lifesaving Training

-

Intelligent Grab Bucket Overhead Crane: Powerful, Precise and Unmanned Bulk Material Handling Solution

-

Custom Multi-Point Suspension Overhead Crane for Large-Span and Load-Sensitive Industrial Buildings

-

Electrolytic Copper Cranes: Specialized in Efficient Cathode Plate Tank Loading and Transfer

-

Nuclear Polar Cranes: Multi-Function Lifting Machinery For Nuclear Power Plants

-

-

Industry Crane

-

Industry Crane

-

Tundish Cranes

-

Slab Cranes

-

Scrap Cranes

-

Billet Cranes

-

Coil,Bar and Plate Handling Cranes

-

Cement And Precast Crane

-

Power Station Crane

-

Ladle Cranes

-

Paper Industry Cranes

-

Waste to Energy Cranes and Biomass Cranes

-

Tailored Overhead Cranes for Aerospace: High Precision, Efficience, Safety and Reliability

-

Anode Baking Multifunctional Cranes: Versatile, High-Temp Resistant & Smart-Controlled Must-Have for Electrolytic Aluminum Industry

-

Multifunctional Crane For Electrolytic Aluminum: Fulfills All Aluminum Electrolysis Processes, Boosts Plant Efficiency

-

Warehouse Stacker Crane for AS/RS: High-Efficiency, Reliable, Fully Automated Storage

-

Slab Handling Overhead Crane: Metallurgical-Grade Crane for Continuous Casting and Slab Yards

-

Anode Carbon Block Stacking Cranes: 6-Layer Stacking, A Lifting Solution for Carbon Plants’ Efficient Transfer

-

Quenching Crane for Heat Treatment: Process-Oriented Overhead Crane Solution

-

Safe & Stable Scrap Charging Overhead Crane for Metallurgical Feeding Operations

-

-

Hoist & Winch Trolley

-

Casting Electric Wire Rope Hoist

-

European Model Electric Hoist

-

Explosion-proof Electric Hoist

-

Low-headroom Electric Hoist

-

Electric Chain Hoist

-

2 Types Explosion-Proof Electric Chain Hoists for Hazardous Zones: Gas & Dust Protection

-

2 Types Explosion-Proof Electric Wire Rope Hoists for Industrial Safety: Reliable Gas & Dust-Proof Solutions

-

Manual Hoists for Precision Lifting: Explore 3 Proven Types for Power-Free Operation

-

Air Pneumatic Hoists: 4 Specialized Designs for Precision, Safety, and Harsh Environments

-

HC Type Electric Hoist: Heavy-duty Wire Rope Hoist for Factory Heavy Lifting

-

-

CRANE Spreader

-

Crane Electromagnetic Lifting Magnets

-

Lifting Electromagnet for Turning and Side Hung

-

Lifting Electromagnet for Thick Plate

-

Specialized Electromagnet for Lifting Steel Plates

-

Lifting Electromagnets for Lifting Steel Plates

-

Lifting Electromagnet for Heavy Rail and Profiled Steel

-

Lifting Electromagnet for High Speed Wier(Coiled Bar)

-

Lifting Electromagnet for Rebar and Steel Pipe

-

Lifting Electromagnet for Bundled Rebar and Profiled Steel

-

Lifting Electromagnet for Billet, Girder Billet and Slab

-

Lifting Electromagnet for Steel Scraps

-

- Crane Spreader

- Crane Hook

- Crane Lifting Tongs and Clamps

-

Crane Electromagnetic Lifting Magnets

- CRANE PARTS

- Transfer Cart

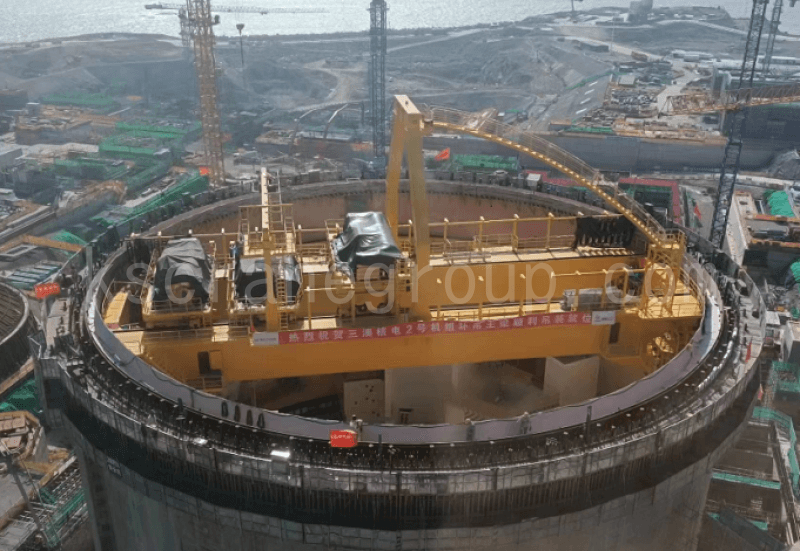

Nuclear Polar Cranes: Multi-Function Lifting Machinery For Nuclear Power Plants

Nuclear polar cranes, commonly referred to as nuclear ring cranes, are a special type of heavy-duty overhead bridge crane designed specifically for the containment buildings of nuclear power plants. Their core function is to serve lifting operations throughout the entire nuclear power generation process. They typically operate on a circular track installed in the upper part of the containment and reactor buildings, enabling full 360° coverage.

Nuclear Polar Cranes Structure

The nuclear polar crane is composed of multiple coordinated mechanisms, each serving a distinct function:

- Main Hoisting Mechanism: Performs core lifting operations, including the hoisting of heavy equipment within the reactor building and routine maintenance tasks.

- Maintenance Gantry: Assists with localized lifting operations during equipment maintenance activities.

- Containment Shell Inspection Platform: Used for the inspection and maintenance of the containment dome.

- Central Arch Girder: Used for the installation of the ring collector and the mounting/dismantling of the installation trolley.

Main Functions of Nuclear Polar Cranes

- During nuclear power plant construction: To install and transport key components within the reactor building, including steam generators, reactor pressure vessels, pressurizers, and other light-duty equipment.

- During plant operation: To handle the loading and unloading of equipment such as pressure vessel heads and internal components during refueling outages, as well as the removal and replacement of fuel assemblies and reactor heads.

- For equipment maintenance and replacement throughout the operational life of the plant.

- During decommissioning: To transport equipment within the reactor building after the plant is retired from service.

Features of Nuclear Polar Cranes: High-Grade, Multi-Purpose Cranes for Nuclear Power Plants

Nuclear polar cranes are advanced, multi-function cranes designed specifically for use in nuclear power plants. Their key features include:

- Versatile Lifting Capabilities: They integrate the main hoisting mechanism, auxiliary hoists, and a maintenance jib crane, enabling them to meet a wide range of lifting requirements.

- Circular Operation: The crane travels along a circular track mounted on a support saddle. This track, formed by multiple joined circular arc segments, provides full 360° coverage around the reactor.

- Safe and Reliable Structural Design: The crane incorporates a fail-safe design where the system remains safely operational even in the event of a single component failure.

- High-Duty Classification: All major mechanisms (except some maintenance devices) are designed for high-duty operation, ensuring durability and performance.

- Robust Box Girder Construction: Key structural components such as the bridge girder, end carriages, ring beam, and central arch girder utilize box girder design. The main girder is fabricated as a single, continuous unit (not segmented), providing superior strength and rigidity.

- High-Strength Steel Materials: Primary load-bearing members are constructed using steel with a minimum grade of Q345 per GB/T 1591. Secondary load-bearing members use steel with mechanical properties not inferior to Q235 per GB/T 700. All load-bearing members preferably utilize killed or semi-killed steel for enhanced performance.

Core Parameters of Nuclear Polar Cranes:

- Trolley Load Capacity: 115 t ~ 360 t

- Circular Track Diameter: 35 m ~ 45 m

- Slewing Angle: 360°

- Power Supply: 3-Phase AC

Nuclear Polar Cranes: Multi-Layered Nuclear Safety System

Equipment used in nuclear power plants is critical to public safety, necessitating the highest grade of protective measures. In compliance with the industry standard JB/T 12214-2015 (Polar Cranes for Nuclear Power Plants), the following technical requirements are specified for the crane’s components:

- Broken Shaft Support for Drum: The hoisting drum assembly is equipped with a broken shaft support device when handling hazardous loads. This device prevents the drum from dropping more than 10 mm in the event of a shaft fracture, thereby averting a load drop. The electrical control system is designed to automatically detect such a shaft or gear shaft fracture and initiate a safe shutdown.

- Broken Axle Support for Wheels & Anti-Derailment: Wheel axles and the support shafts for balancing devices are fitted with a support mechanism to limit the drop to a maximum of 25 mm should an axle fracture occur. Additionally, both the crane bridge and trolley are equipped with anti-derailment devices.

- Overspeed Protection:* The main hoisting mechanism incorporates two independent overspeed protection systems that are effective during high-speed operation under a weak magnetic field with no load. Should an overspeed condition occur, the crane will automatically engage its brakes.

- Overload & Underload Protection: In an overload situation, the hoisting mechanism is prevented from lifting further and is only permitted to lower the load. Conversely, in an underload condition, the hoisting mechanism is prevented from initiating a lowering operation.

Nuclear Polar Cranes: Professional Installation, Precision Delivery

Our delivery ensures precision from the ground up, guaranteeing performance and reliability for decades of critical service.

- High-Precision Track System: Utilizing nuclear-grade wear-resistant materials and millimeter-level precision positioning, we ensure that the circular track’s horizontal and vertical alignment is controlled within a ±1 mm tolerance. This foundational accuracy guarantees the crane’s smooth, quiet 360° operation and significantly extends its service life.

- Digitalized Bridge Assembly: Through advanced 3D laser scanning and digital pre-assembly technology, we identify and eliminate all potential fit-up interferences in a virtual environment. This enables successful on-site assembly in a single lift, dramatically reducing critical path timelines.

- Intelligent Hoisting Mechanism: Calibration is integrated into the installation process. Equipped with high-precision sensors, the system actively senses and suppresses load swing in real-time, reducing swing amplitude by over 50%. This significantly enhances placement accuracy and operational safety.

- Smart Electrical System: The electrical system undergoes 100% pre-commissioning prior to installation. Featuring intelligent power distribution and a remote operations & maintenance platform, it enables real-time status monitoring, minute-level fault diagnosis, and energy efficiency optimization. This ensures lifelong system reliability and can improve maintenance efficiency by up to 30%.

Simulation of Key Installation Steps for the Nuclear Polar Crane

Get in Touch

- Free and fast quote for the product.

- Provide you our product catalog.

- Your local crane projects from our company.

- Become our agent and earn commission.

- Any questions, contact us.

.png?w=200&h=134)