- EQUIPMENT

-

special cranes

-

Garbage Grab Crane

-

Foundry Overhead Crane

-

Explosion-proof Overhead Crane

-

Tongs Overhead Crane

-

Overhead Crane with Carrier-beam

-

Electromagnetic Overhead Cranes

-

Diesel Hydraulic Straddle Carrier: Flexible Operation and Affordable Solution for Container Handling

-

Upper Spillway Gate Gantry Crane: Reliable Solution for Dam Gate Hoisting and Hydropower Station Operations

-

Harbour Portal Crane: Powerful and Intelligent Solutions for Efficient Port Handling

-

Coke Pot Crane for CDQ: Exceptional Heavy-Duty Red-Hot Coke Handling

-

Emergency Rescue Specialized Crane for Water-Rescue Simulation: Engineered for Lifesaving Training

-

Intelligent Grab Bucket Overhead Crane: Powerful, Precise and Unmanned Bulk Material Handling Solution

-

Custom Multi-Point Suspension Overhead Crane for Large-Span and Load-Sensitive Industrial Buildings

-

Electrolytic Copper Cranes: Specialized in Efficient Cathode Plate Tank Loading and Transfer

-

Nuclear Polar Cranes: Multi-Function Lifting Machinery For Nuclear Power Plants

-

-

Industry Crane

-

Industry Crane

-

Tundish Cranes

-

Slab Cranes

-

Scrap Cranes

-

Billet Cranes

-

Coil,Bar and Plate Handling Cranes

-

Cement And Precast Crane

-

Power Station Crane

-

Ladle Cranes

-

Paper Industry Cranes

-

Waste to Energy Cranes and Biomass Cranes

-

Tailored Overhead Cranes for Aerospace: High Precision, Efficience, Safety and Reliability

-

Anode Baking Multifunctional Cranes: Versatile, High-Temp Resistant & Smart-Controlled Must-Have for Electrolytic Aluminum Industry

-

Multifunctional Crane For Electrolytic Aluminum: Fulfills All Aluminum Electrolysis Processes, Boosts Plant Efficiency

-

Warehouse Stacker Crane for AS/RS: High-Efficiency, Reliable, Fully Automated Storage

-

Slab Handling Overhead Crane: Metallurgical-Grade Crane for Continuous Casting and Slab Yards

-

Anode Carbon Block Stacking Cranes: 6-Layer Stacking, A Lifting Solution for Carbon Plants’ Efficient Transfer

-

Quenching Crane for Heat Treatment: Process-Oriented Overhead Crane Solution

-

Safe & Stable Scrap Charging Overhead Crane for Metallurgical Feeding Operations

-

Forging Overhead Crane: Reliable Lifting Equipment for Heavy-Duty Forging Workshops

-

Mold Handling Crane for AAC Production Line: Reliable Engineered Fixed-Position Lifting Solution

-

Pickling Overhead Cranes: For Acid Mist Environments in Non-ferrous Metal Smelting

-

-

Hoist & Winch Trolley

-

Casting Electric Wire Rope Hoist

-

European Model Electric Hoist

-

Explosion-proof Electric Hoist

-

Low-headroom Electric Hoist

-

Electric Chain Hoist

-

2 Types Explosion-Proof Electric Chain Hoists for Hazardous Zones: Gas & Dust Protection

-

2 Types Explosion-Proof Electric Wire Rope Hoists for Industrial Safety: Reliable Gas & Dust-Proof Solutions

-

Manual Hoists for Precision Lifting: Explore 3 Proven Types for Power-Free Operation

-

Air Pneumatic Hoists: 4 Specialized Designs for Precision, Safety, and Harsh Environments

-

HC Type Electric Hoist: Heavy-duty Wire Rope Hoist for Factory Heavy Lifting

-

-

CRANE Spreader

-

Crane Electromagnetic Lifting Magnets

-

Lifting Electromagnet for Turning and Side Hung

-

Lifting Electromagnet for Thick Plate

-

Specialized Electromagnet for Lifting Steel Plates

-

Lifting Electromagnets for Lifting Steel Plates

-

Lifting Electromagnet for Heavy Rail and Profiled Steel

-

Lifting Electromagnet for High Speed Wier(Coiled Bar)

-

Lifting Electromagnet for Rebar and Steel Pipe

-

Lifting Electromagnet for Bundled Rebar and Profiled Steel

-

Lifting Electromagnet for Billet, Girder Billet and Slab

-

Lifting Electromagnet for Steel Scraps

-

- Crane Spreader

- Crane Hook

- Crane Lifting Tongs and Clamps

-

Crane Electromagnetic Lifting Magnets

- CRANE PARTS

- Transfer Cart

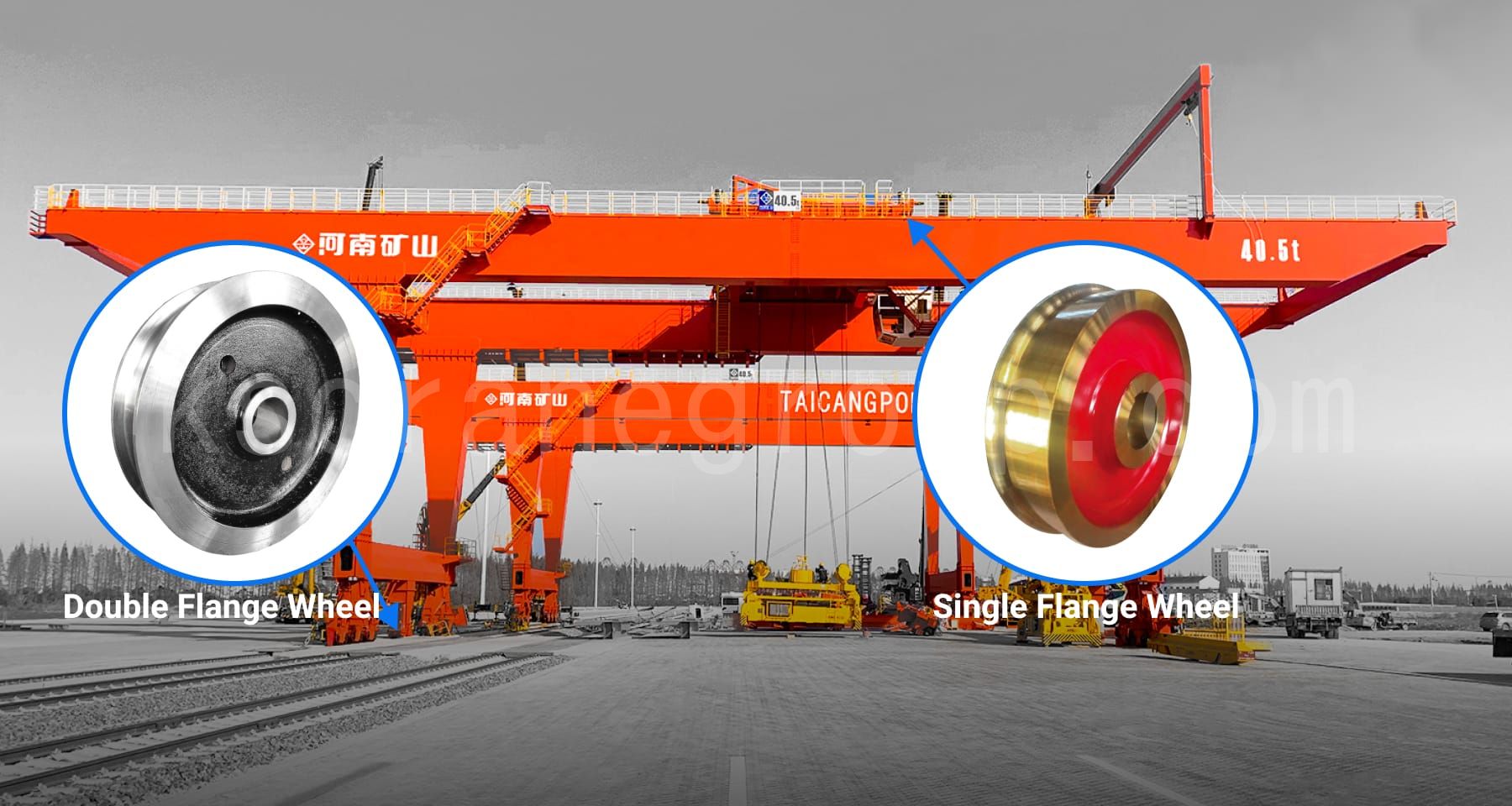

Gantry Crane Wheel: The Ultimate Guide to Types, Applications, and High-Performance Wheel Assemblies

The gantry crane wheel is one of the key components of a gantry crane's traveling mechanism. It plays a crucial role in supporting the overall weight of the crane, guiding its movement along the rail, and transmitting driving force.

Although its appearance seems simple, the wheel's design determines whether the entire gantry crane can operate smoothly, safely, and reliably over a long period. Whether it's a single girder gantry crane or a heavy-duty double girder gantry crane, the design, material selection, and installation precision of the wheel system directly affect the overall performance and service life of the equipment.

In a gantry crane, the wheel system is mainly distributed in two operating mechanisms:

- Crane Traveling Mechanism: Responsible for the longitudinal movement of the entire crane along the ground rails.

- Trolley Traveling Mechanism: Responsible for the lateral movement of the hoisting trolley along the main beam.

Different operating mechanisms impose distinct structural and performance requirements on the wheels.

Types of Gantry Crane Wheels

Gantry crane wheels can be classified according to their flange structure into single flange wheels, double flange wheels, and flangeless wheels.

Structural Features: Has a flange on one side, providing directional guidance while allowing lateral movement with reduced friction against the rail.

Application: Used on the trolley traveling mechanism, where it runs laterally along the main beam to ensure smooth movement and minimize rail wear.

Structural Features: Equipped with flanges on both sides to prevent derailment and provide more stable guidance.

Application: Installed on the crane traveling mechanism, which moves longitudinally along the ground or runway beam. Ideal for heavy-duty and long-travel applications.

Structural Features: Designed without flanges, completely eliminating flange-to-rail friction.

Application: Commonly used on semi-gantry cranes that operate without rails, where the wheel runs directly on a steel plate surface.

Application of Gantry Crane Wheels in Cranes

In gantry cranes, different types of wheels perform distinct operational roles. To help visualize their distribution and function, the illustration below shows the typical installation positions of single flange, double flange, and flangeless wheels in gantry cranes.

- Single Flange Wheel: Typically mounted on the trolley traveling mechanism, allowing the trolley to move laterally along the main beam. The single-side flange provides guidance, ensuring the trolley maintains alignment during high-frequency reciprocating motion.

- Double Flange Wheel: Commonly used in the crane traveling mechanism (beneath the end beams), responsible for the longitudinal movement of the entire crane along ground rails. The double flanges enhance guidance and prevent derailment, making them ideal for heavy loads and long-distance travel.

- Flangeless Wheel: Mainly applied to semi-gantry cranes operating without rails, where the wheel runs directly on a flat steel plate. This design allows for flexible movement and smoother travel.

This structural division ensures that the gantry crane maintains stable, smooth, and safe motion across different directions of operation.

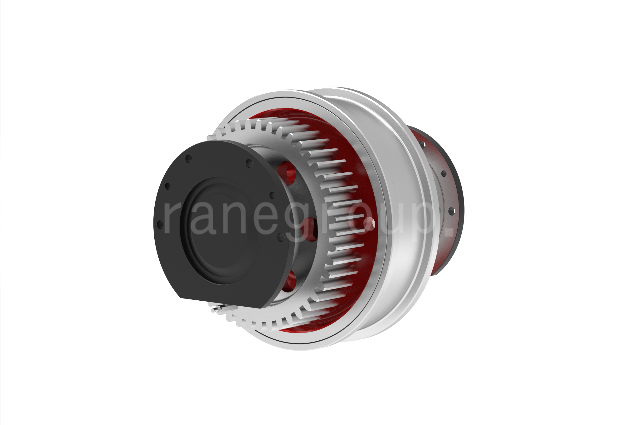

Types of Gantry Crane Wheel Block Assemblies

Gantry crane wheels are typically assembled with components such as axles, bearings, bearing housings, seals, and mounting bases to form wheel block assemblies. These assemblies serve as the connection between the wheels and the drive mechanism, bearing the load, transmitting driving force, and ensuring smooth operation — making them a core component of the gantry crane's traveling mechanism.

The wheel block assemblies can be categorized by structure into:

- Made of materials such as 42CrMo, ZG50SiMn, 65Mn, and ZG340–640;

- Simple structure, easy installation, and convenient maintenance;

- Strong support rigidity and high cost performance;

- Suitable for both trolley and crane traveling mechanisms.

- Forged from 42CrMo and 65Mn with a wear-resistant surface;

- Compact, modular structure for easy installation;

- High transmission efficiency and large load-bearing capacity, with optional precision positioning;

- Commonly applied in European-type gantry cranes (FEM / DIN standard structures).

- The bearing box adopts a 45° split design;

- Installation and maintenance can be performed without full disassembly, effectively reducing downtime;

- High wear resistance and excellent impact performance.

- Made of ZG50SiMn, 42CrMo, 65Mn, and other high-strength materials.

- High transmission efficiency and large wheel load capacity.

- Mainly used in industries such as ports and construction machinery.

Below are the parameter ranges and technical data for commonly used gantry crane wheel assemblies.

You can download the detailed PDF technical datasheet to view specific models, wheel diameters, bearing specifications, and installation dimensions.

Applications of Gantry Crane Wheel Block Assemblies

Selection and Customization Service

KUANGSHAN CRANE can design matching wheel assemblies based on the rail model, crane type, duty class, and working environment provided by the customer.

Available Specifications:

- Wheel Diameter: 160mm – 1000mm

- Material Options: 42CrMo / 65Mn / ZG50SiMn / ZG340–640

- Structural Types: L-Type, 45° Split, Round Bearing Box

- Mounting Interface: Keyed Shaft / Splined Shaft / Bolted Connection

- Surface Treatment: Painting / Phosphating / Galvanizing

Customization Capabilities:

- European or Chinese standard mounting dimensions;

- Support for non-standard rail gauge designs;

- Smart wheel assemblies with encoders or correction devices;

- Optional sealed bearings or high-temperature-resistant bearings.

How to Choose the Right Gantry Crane Wheel?

When selecting gantry crane wheels, consider the following factors comprehensively:

- Load and Operating Frequency: For heavy-duty or high-frequency use, forged steel wheels are recommended.

- Rail Type: Different rail models (such as P43, QU70, QU80) require matching flange dimensions.

- Operating Environment: Corrosive, explosive, or dusty environments may require special surface treatments or stainless steel wheels.

- Drive System Compatibility: Ensure precise matching with the reducer, bearing seat, and coupling.

A professional manufacturer can provide customized wheel assembly solutions to ensure proper installation dimensions, fitting accuracy, and balanced operation.

KUANGSHAN CRANE Advantages

- Integrated production line for forging, heat treatment, machining, and testing;

- Over 20 years of experience in manufacturing crane wheel assemblies;

- Exported to over 50 countries, serving industries such as ports, metallurgy, and shipbuilding;

- Certified by ISO, CE, and FEM international standards;

- Each wheel assembly includes a material and flaw detection report.

KUANGSHAN CRANE Wheel Production Line

All Kuangshan products are equipped with forged wheels as standard, covering all types of cranes.

The production process integrates heating, conveying, forging, rolling, heat treatment, and continuous machining — achieving fast production cycles, high efficiency, and short delivery times.

High-quality raw materials are carefully selected, and a 10,000-ton press applies strong pressure to forge a tough core.

The result is superior performance, dense structure, refined grains, and greatly enhanced strength, toughness, and fatigue life of the material.

KUANGSHAN CRANE Wheel Export Cases

Conclusion

Gantry Crane Wheel is the most critical load-bearing and guiding component in a gantry crane system.

Its high-strength materials, precision machining, and optimized design not only enhance crane operating stability but also significantly extend service life.

With extensive manufacturing experience and rigorous quality control, KUANGSHAN CRANE provides reliable and durable wheel and wheel assembly solutions for customers worldwide. For any inquiries or customization needs regarding gantry crane wheels, our professional crane engineers are available 24/7 to provide one-on-one assistance.

Get in Touch

- Free and fast quote for the product.

- Provide you our product catalog.

- Your local crane projects from our company.

- Become our agent and earn commission.

- Any questions, contact us.

.png?w=200&h=134)